Dual Zone Wireless Pulp Washer

a pulp washer and wireless technology, applied in the direction of centrifuges, separation processes, filtration separation, etc., can solve the problem of limited rotational speed of wire thickeners or washers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

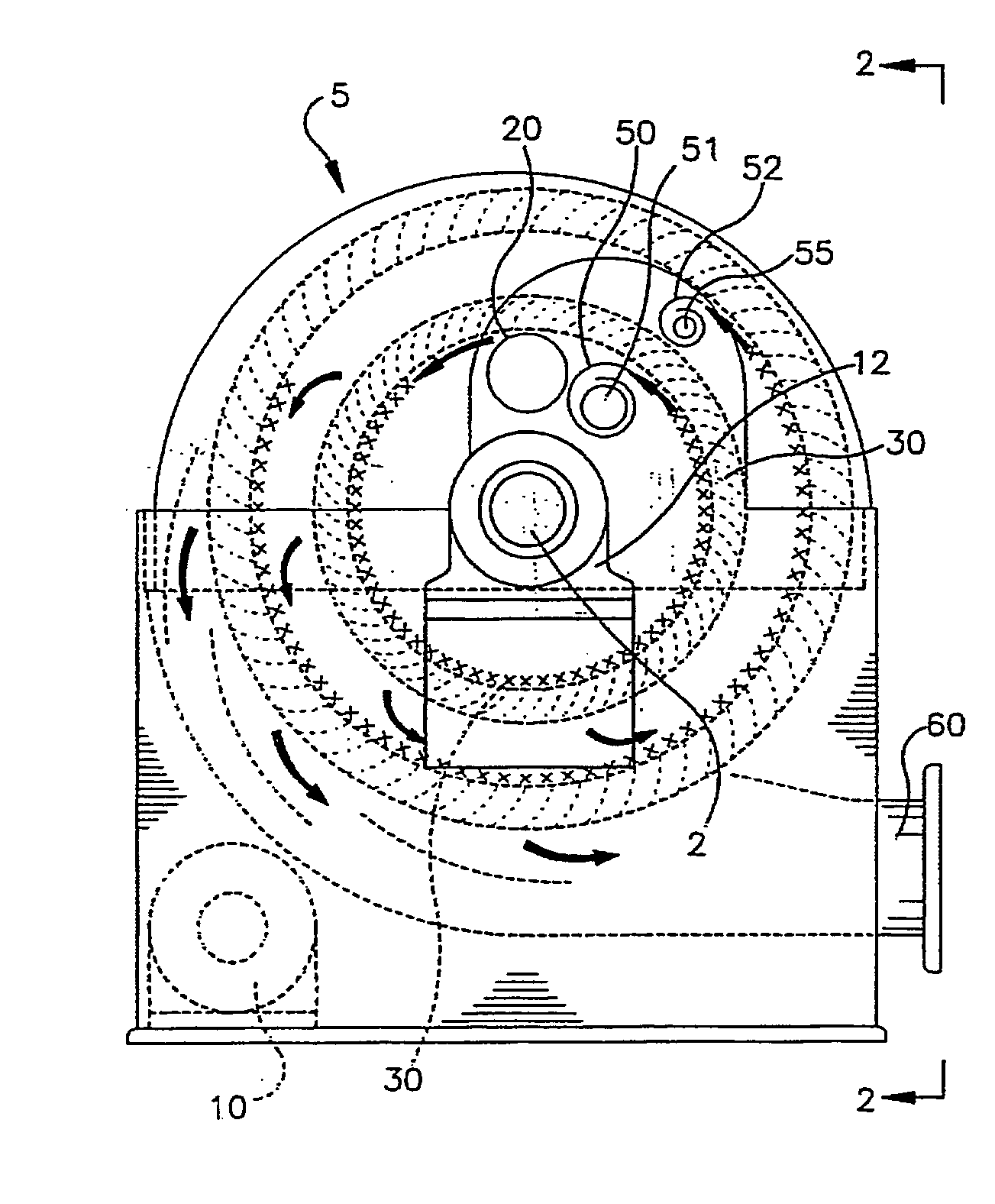

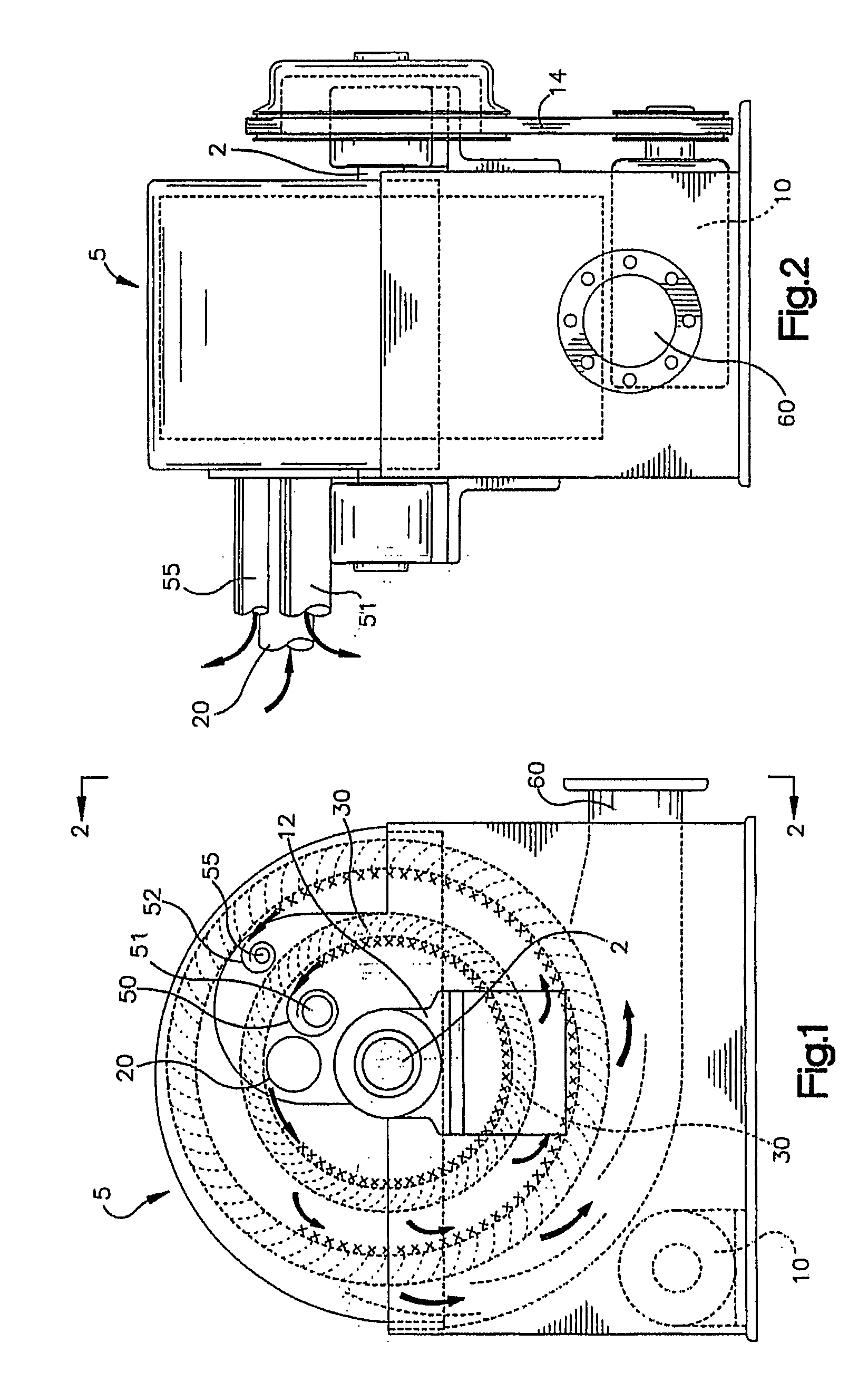

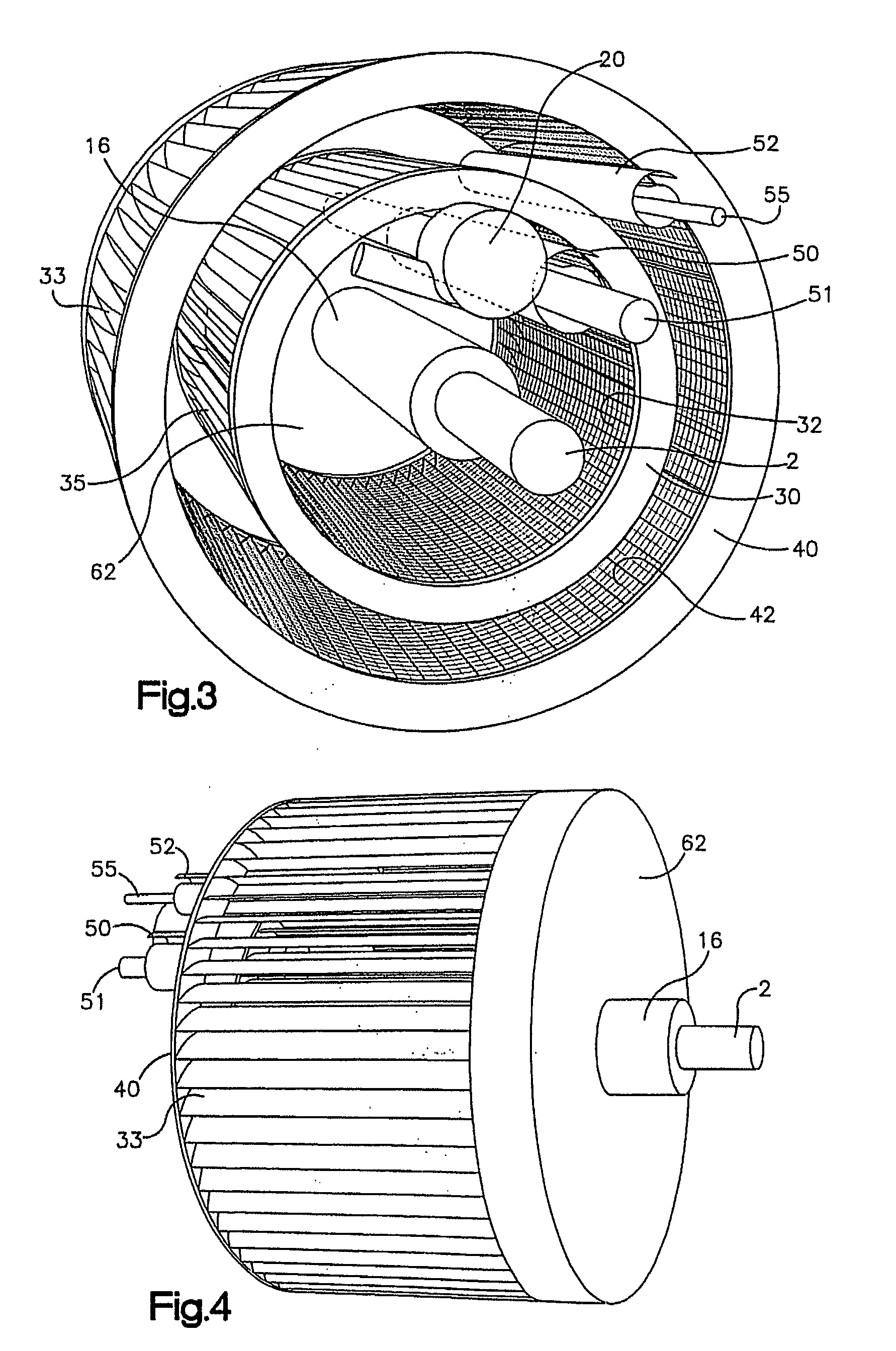

[0020] The invention will be described with reference to the drawings. FIG. 1 illustrates a structure of a pulp thickening or dewatering apparatus 5. The structure operates with a motor 10 and includes a headbox 20 for delivering feedstock and a primary cylindrical filter 30 for thickening the pulp.

[0021] Feedstock is delivered to the apparatus 5 similarly to the prior art thickeners or washers. The headbox 20, shown in FIG. 3, delivers a jet of feedstock onto an inner surface 32 of the primary cylindrical filter 30. Feedstock to be thickened or dewatered is fed to the headbox 20 by a feedline (not shown) from a typical stock supply pump (not shown).

[0022] The motor 10, shown in FIGS. 1 and 2, drives axle 2 housed in bearing journal 12, shown in FIG. 4. The motor 10 rotates the primary cylindrical filter 30 through belt 14. Headbox 20 delivers the feedstock to the inner surface 32. Centrifugal force is created by the rotation of the cylindrical filter 30 and controlled by the set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lengths | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| centrifugal force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com