Bamboo pulp denatured productive technology

A production process, bamboo pulp technology, applied in the field of bamboo fiber viscose pulp production process, can solve the problems of poor reaction performance, environmental pollution, low cellulose percentage content, etc., and achieve the effect of reducing the discharge of production wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

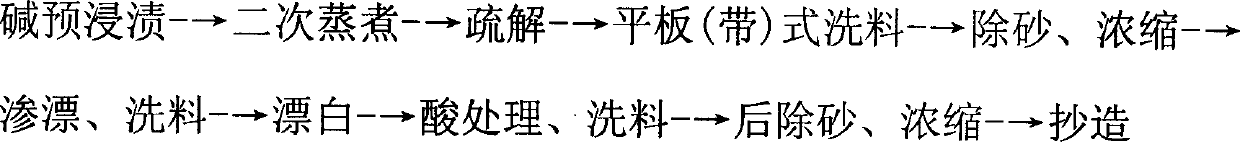

[0024] As shown in the figure, the process flow chart of the present invention, the specific process is by: 1, alkali pre-impregnation; 2, secondary cooking; Bleaching and washing materials; 7. Bleaching; 8. Acid treatment and washing materials; 9. Post-sand removal and concentration; 10. Copying. in:

[0025] 1. Alkali pre-impregnation, the insoluble bamboo pulp products are opened and removed by the cotton opener, and then fed to the screw press after cyclone separation and alkali spraying to squeeze the insoluble bamboo pulp fibers after crushing and alkali pre-impregnation Penetration is to prepare for improving the purity of cellulose A and reducing the degree of polymerization in the denatured production of bamboo pulp, and to lay the foundation for the cooking uniformity of the second cooking.

[0026] Main technical parameters: the amount of alkali (NaOH) used is 19-26%, the bath ratio is 1:3.75-1:3.90, and the temperature of feeding into the steaming ball is ≥80°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com