Flexible nanocellulose-graphene composite membrane and preparation method thereof

A composite technology of nanocellulose and graphene, applied in chemical instruments and methods, materials for heat exchange, etc., can solve the problems of poor mechanical properties such as strength and toughness of pure graphite film, poor compatibility between graphene and silicone rubber, etc. , to achieve the effects of good mechanical properties, excellent flexibility and bending resistance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

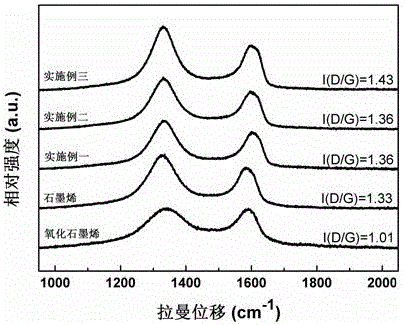

Embodiment 1

[0020] A kind of preparation method of flexible nanocellulose-graphene composite film of the present embodiment, comprises the following steps:

[0021] (1). 0.0075g of graphene oxide and 0.1425g of nanocellulose were added to the dispersant respectively, and the graphene oxide dispersion liquid with a concentration of 0.075mg / ml and the nanocellulose dispersion with a concentration of 1.425mg / ml were prepared respectively. solution, ultrasonically dispersed for 1 h, then mixed the above graphene oxide dispersion with the above nanocellulose dispersion at a volume ratio of 1:1, continued stirring and ultrasonication for 0.5 h, to obtain nanocellulose-graphite oxide with a concentration of 0.75 mg / ml The first dispersion liquid of vinyl, described dispersant is deionized water;

[0022] (2). Add a reducing agent to the first dispersion of nanocellulose-graphene oxide obtained in the above step (1), raise the temperature to 90°C, stir for 5 hours, and stir evenly to obtain the s...

Embodiment 2

[0026] The preparation method of a kind of flexible nanocellulose-graphene composite membrane of the present embodiment comprises the following steps:

[0027] (1). 0.03g of graphene oxide and 0.12g of nanocellulose were added to the dispersant respectively, and the graphene oxide dispersion with a concentration of 0.3mg / ml and the nanocellulose with a concentration of 1.2mg / ml were prepared respectively. Dispersion, ultrasonic dispersion for 1h, then mix the above graphene oxide dispersion with the above nanocellulose dispersion at a volume ratio of 1:1, continue stirring and ultrasonication for 0.5h, to obtain a concentration of 0.75mg / ml of nanocellulose-oxidized The first dispersion liquid of graphene, described dispersant is deionized water;

[0028] (2). Add a reducing agent to the first dispersion of nanocellulose-graphene oxide obtained in the above step (1), raise the temperature to 95°C, stir for 2 hours, and stir evenly to obtain the second dispersion of nanocellulo...

Embodiment 3

[0032] A kind of preparation method of flexible nanocellulose-graphene composite film of the present embodiment, comprises the following steps:

[0033](1). 0.06g of graphene oxide and 0.14g of nanocellulose were added to the dispersant respectively, and the graphene oxide dispersion with a concentration of 0.6mg / ml and the nanocellulose with a concentration of 1.4mg / ml were prepared respectively. Dispersion, ultrasonic dispersion for 1h, then the above-mentioned graphene oxide dispersion and the above-mentioned nanocellulose dispersion were mixed at a volume ratio of 1:1, continued stirring and ultrasonication for 0.5h, to obtain nanocellulose-graphite oxide with a concentration of 1mg / ml The first dispersion liquid of vinyl, described dispersant is deionized water;

[0034] (2). Add a reducing agent to the first dispersion of nanocellulose-graphene oxide obtained in the above step (1), raise the temperature to 90°C, stir for 6 hours, and stir evenly to obtain the second disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com