Preparation method of polylactic acid/nano-cellulose composite material

A nanocellulose and composite material technology is applied in the field of preparation of polylactic acid/nanocellulose composite materials to achieve the effects of improving interfacial adhesion, convenient and quick preparation, and solving the problem of uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

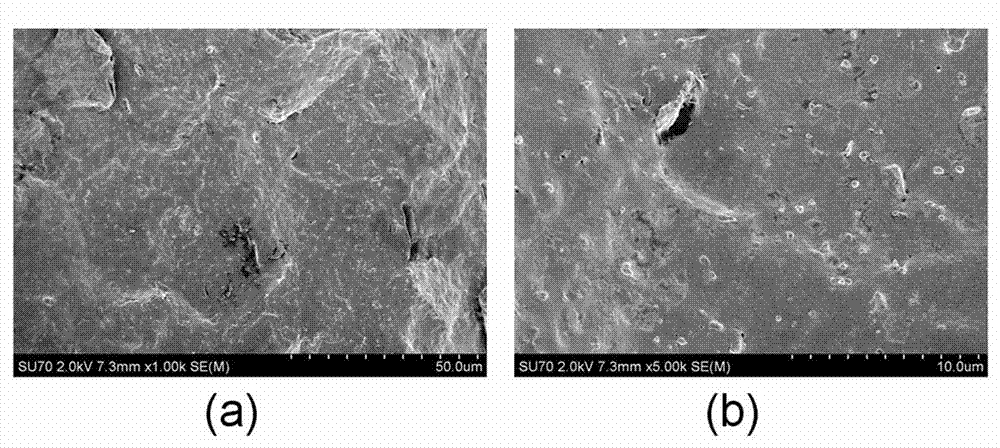

Image

Examples

Embodiment 1

[0018] A kind of preparation method of polylactic acid / nanocellulose composite material, described polylactic acid / nanocellulose composite material comprises each component of following percentage by weight: polylactic acid 84%, nanocellulose 6%, polyethylene glycol 10% , the preparation method comprises the following steps:

[0019] (1) Preparation of nanocellulose suspension by acid hydrolysis: Prepare an aqueous solution of microcrystalline cellulose (5 g of microcrystalline cellulose) with a mass percentage of 10%, and then add it dropwise to the aqueous solution of microcrystalline cellulose while stirring in an ice-water bath Concentrated sulfuric acid until the concentration of sulfuric acid reaches 50%, stir and react at 40°C for 1.5h, centrifuge the resulting suspension at 12000rpm for 10min, remove the supernatant, repeat five times, and ultrasonicate the centrifuged sample 3 times in an ice-water bath, each time Sonicate for 10 minutes, and then adjust the pH value ...

Embodiment 2

[0023] A preparation method of polylactic acid / nanocellulose composite material, said polylactic acid / nanocellulose composite material comprises the following components in weight percentage: polylactic acid 88%, nanocellulose 2%, polyethylene glycol 10% , the preparation method comprises the following steps:

[0024] (1) Preparation of nanocellulose suspension by acid hydrolysis: Prepare an aqueous solution of microcrystalline cellulose (5 g of microcrystalline cellulose) with a mass percentage of 10%, and then add it dropwise to the aqueous solution of microcrystalline cellulose while stirring in an ice-water bath Concentrated sulfuric acid until the concentration of sulfuric acid reaches 50%, stir and react at 40°C for 1.5h, centrifuge the resulting suspension at 12000rpm for 10min, remove the supernatant, repeat five times, and ultrasonicate the centrifuged sample 3 times in an ice-water bath, each time Sonicate for 10 minutes, and then adjust the pH value to neutral with ...

Embodiment 3

[0028] A kind of preparation method of polylactic acid / nanocellulose composite material, described polylactic acid / nanocellulose composite material comprises each component of following percentage by weight: polylactic acid 88%, nanocellulose 6%, polyethylene glycol 6% , the preparation method comprises the following steps:

[0029] (1) Preparation of nanocellulose suspension by acid hydrolysis: Prepare an aqueous solution of microcrystalline cellulose (10 g of microcrystalline cellulose) with a mass percentage of 10%, and then add it dropwise to the aqueous solution of microcrystalline cellulose while stirring in an ice-water bath Concentrated sulfuric acid until the concentration of sulfuric acid reaches 50%, stir and react at 40°C for 1.5h, centrifuge the resulting suspension at 12000rpm for 10min, remove the supernatant, repeat five times, and ultrasonicate the centrifuged sample 3 times in an ice-water bath, each time Sonicate for 10 minutes, and then adjust the pH value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com