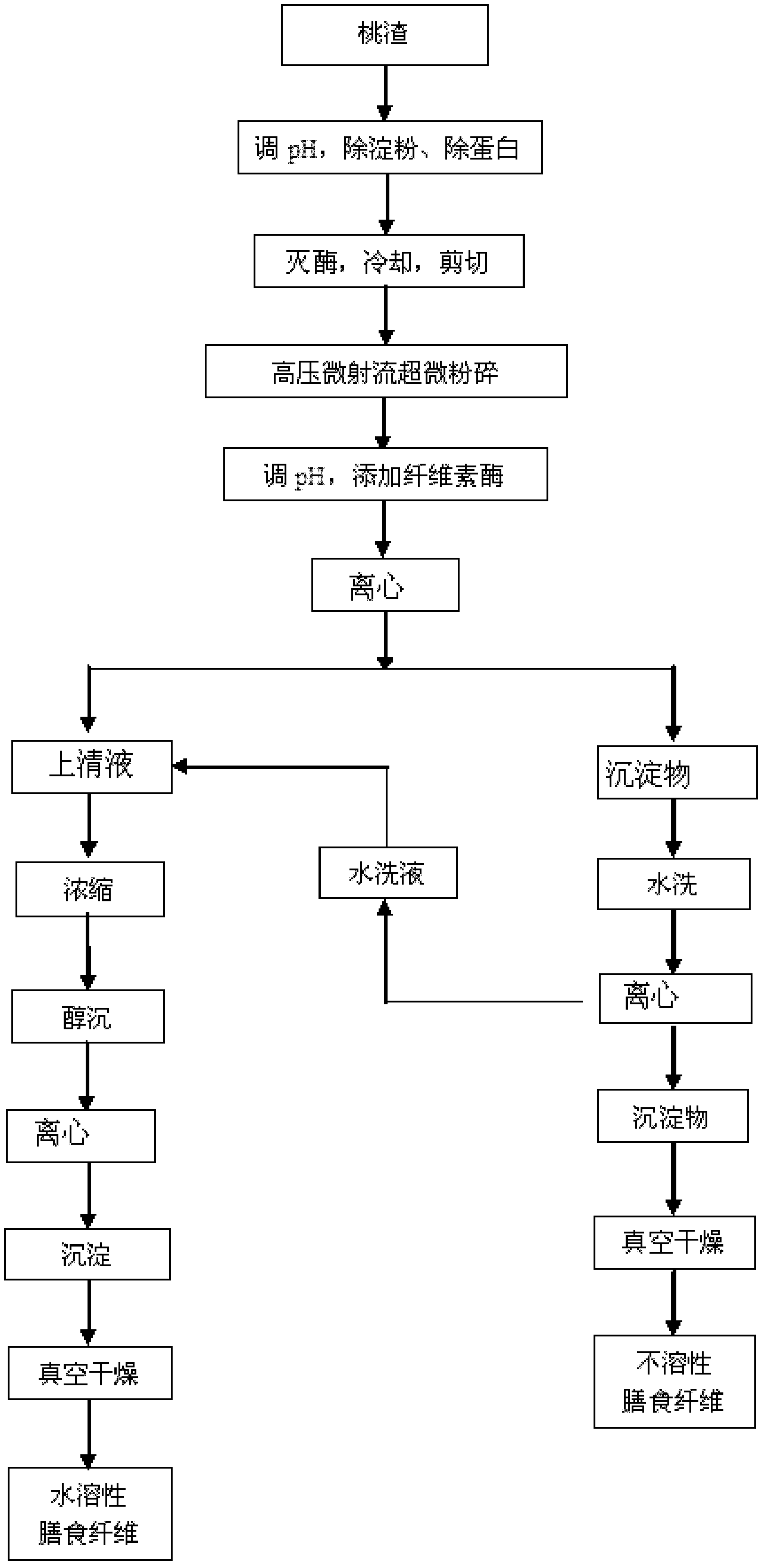

Method for extracting fruit dreg dietary fiber through high-pressure microfluidization ultramicro crushing and enzymolysis coupling

A high-pressure micro-jet and ultrafine pulverization technology, which is applied in food preparation, food science, application, etc., can solve the problems of lack of effective combination, low extraction efficiency, and low product activity, so as to change the composition and structure and improve the extraction rate , the effect of preventing obesity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Take 50 g of peach residue (water content 70%) left after squeezing the juice, add water to disperse, the ratio of peach residue to water is 1:5, stir evenly, adjust the pH to 6 with 1mol / l NaOH solution, and make peach Slurry.

[0033] 2) Removal of starch: add high temperature resistant α-amylase (enzyme activity: 70,000-80,000 U / g) to the peach pulp pulp, the amount of enzyme added is 0.1% of the mass of the peach pulp pulp, and stir at 95°C Enzyme hydrolysis for 30min.

[0034] 3) Protein removal: after cooling the enzymatically hydrolyzed peach pulp to 40°C, add neutral protease (enzyme activity: 0.6-2.0 AU / g), the amount of enzyme added is 0.016% of the mass of the enzymatically hydrolyzed peach pulp. Stir and enzymatically hydrolyze at 60°C for 30 minutes.

[0035] 4) Enzyme inactivation: inactivate the enzyme in a 95°C water bath for 2 minutes, and cool to room temperature.

[0036] 5) Shearing: Treat the enzyme-inactivated peach residue pulp with a high-s...

Embodiment 2

[0043] 1) Take 100 g of peach residue (water content 80%) left after squeezing the juice, add water to disperse, the ratio of peach residue to water is 1:4, stir evenly, adjust the pH to 6.5 with 1mol / l NaOH solution, and make peach Slurry.

[0044] 2) Removal of starch: Add high-temperature-resistant α-amylase (enzyme activity: 70,000 to 80,000 U / g) to the peach pulp, the amount of enzyme added is 0.12% of the mass of the peach pulp, and the enzyme is stirred at 90°C Solution 40min.

[0045] 3) Protein removal: after cooling the enzymatically hydrolyzed peach pulp to 45°C, add neutral protease (enzyme activity: 0.6-2.0AU / g), the amount of enzyme added is 0.01% of the mass of the enzymatically hydrolyzed peach pulp. Stir and enzymatically hydrolyze at 55°C for 40 minutes.

[0046] 4) Enzyme inactivation: inactivate the enzyme in a 95°C water bath for 2 minutes, and cool to room temperature.

[0047] 5) Shearing: Treat the enzyme-inactivated peach residue pulp with a high-sp...

Embodiment 3

[0054] 1) Take 500 g of peach residue (water content 90%) left after squeezing the juice, add water to disperse, the mass ratio of peach residue to water is 1:3, stir evenly, adjust the pH to 5.5 with 1mol / l NaOH solution, and prepare Peach pulp.

[0055] 2) Removal of starch: Add high-temperature-resistant α-amylase (enzyme activity: 70,000 to 80,000 U / g) into the peach pulp, the amount of enzyme added is 0.2% of the mass of the peach pulp, and the enzyme is stirred at 85°C Solution 60min.

[0056] 3) Protein removal: after cooling the enzymatically hydrolyzed peach pulp to 55°C, add neutral protease (enzyme activity: 0.6-2.0AU / g), the amount of enzyme added is 0.02% of the mass of the peach pulp, at 65°C Enzymolysis under stirring for 30min.

[0057] 4) Enzyme inactivation: inactivate the enzyme in a 95°C water bath for 2 minutes, and cool to room temperature.

[0058] 5) Shearing: the enzyme-inactivated peach pulp was treated with a high-speed shearer for 15 minutes at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Water holding capacity | aaaaa | aaaaa |

| Oil holding power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com