'Puer' caffeine and processing method

A technology of Pu-erh tea essence and processing method, applied in the direction of tea extraction and the like, can solve the problems of poor quality of tea essence (paste), large loss of effective components and aroma, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

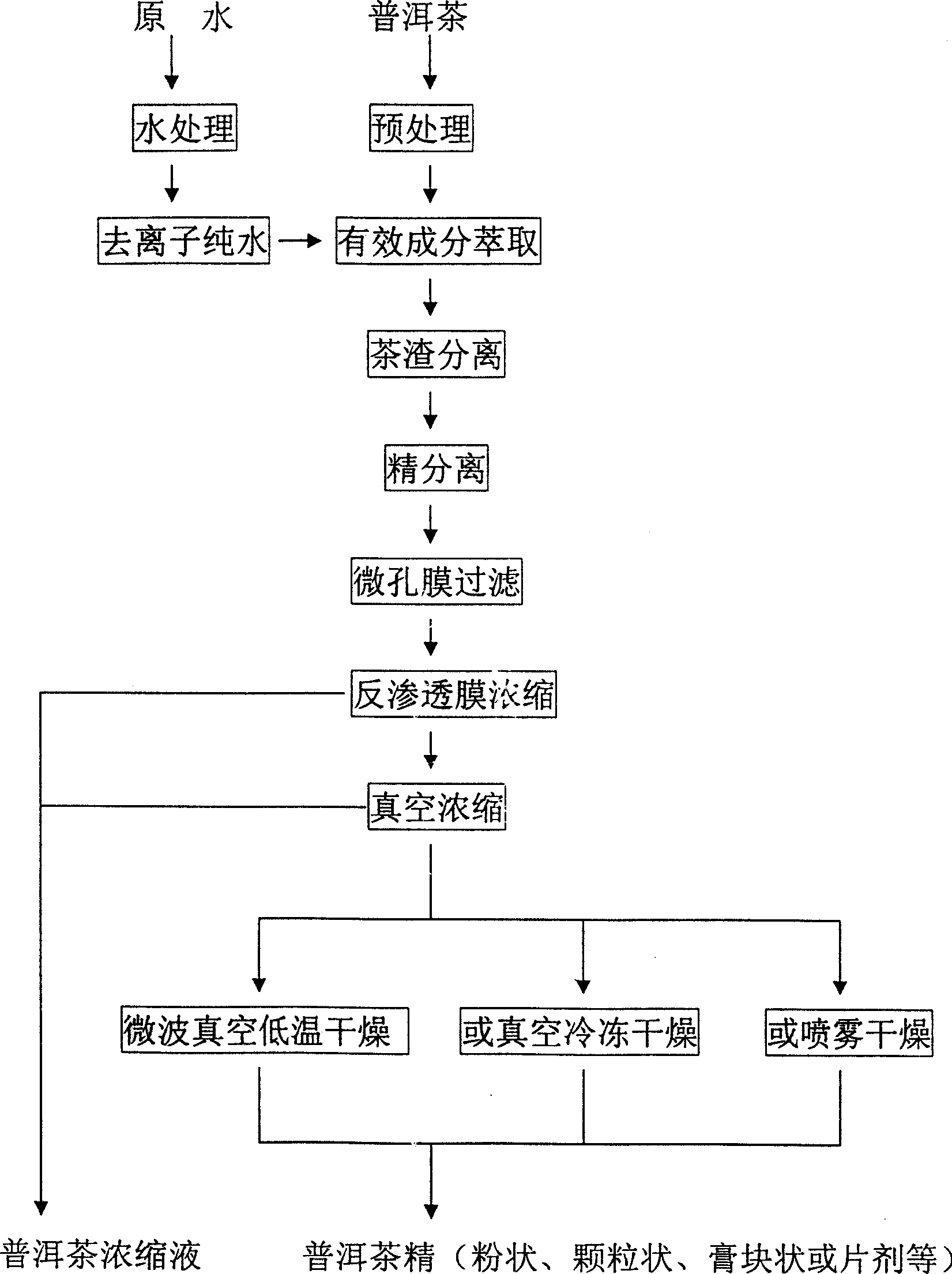

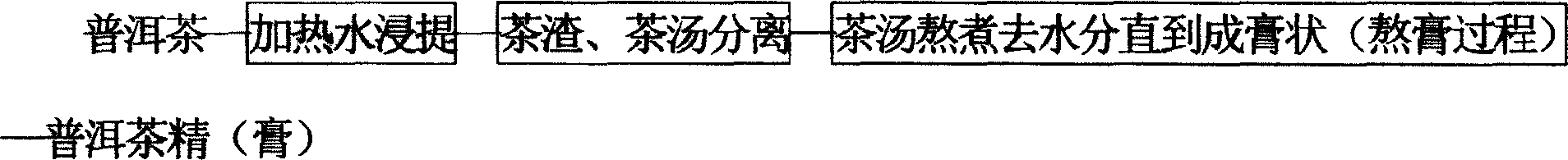

Method used

Image

Examples

Embodiment 1

[0026] 1. Puer tea is pretreated. Sorting out the non-tea substances such as grass, wood chips and other impurities in the Pu-erh tea used, and crushing the tea leaves with a pulverizer, and the fineness is required to reach 8 mesh or less;

[0027] 2. Treat the water used in the extraction process to obtain deionized pure water.

[0028] 3. 10 kg of tea leaves obtained by pretreatment and 80 kg of process water are extracted at 55°C. The extraction was carried out twice, 60 minutes each. The tea soup filtered out after the two extractions was combined and cooled to room temperature to obtain a rough filtrate of the tea soup.

[0029] 4. Carry out fine separation of the coarse filtrate of the tea soup after cooling, and filter with a precision membrane to further remove fine particles in the tea leaves. The pore size of the precision membrane filter is 3-10 μm to obtain the fine filtrate of the tea soup.

[0030] 5. Filter the refined filtrate with a microporous membrane, w...

Embodiment 2

[0037] The processing method of Pu'er tea essence is basically the same as embodiment one, only slightly different in quantity. 30 kg of tea leaves obtained by pretreatment and 360 kg of process water were extracted at 80°C. Extraction was carried out 3 times, 40 minutes each. The tea soup filtered out after three extractions was combined and cooled to room temperature to obtain a rough filtrate of the tea soup. The refined purified liquid is concentrated with a reverse osmosis membrane to obtain a concentrated tea soup with a solid content of about 12%. The tea soup concentrated by the reverse osmosis membrane is then concentrated under vacuum and reduced pressure, and the tea soup is concentrated to a solid content of about 25% at a low temperature of about 45°C. Put the concentrated liquid into a forming vessel, carry out microwave vacuum low-temperature drying, control the drying time, and finally obtain the concentrated Pu'er tea essence or Pu'er tea essence powder.

...

Embodiment 3

[0041] The same steps are omitted, and 50 kg of tea leaves obtained by pretreatment and 750 kg of process water are extracted at 95°C. Extraction was performed 4 times, 15 minutes each. The tea soup filtered out after the 4 extractions was combined and cooled to room temperature to obtain a rough filtrate of the tea soup. Concentrate the refined purified liquid with a reverse osmosis membrane to obtain a concentrated tea soup with a solid content of about 15%. The tea soup concentrated by the reverse osmosis membrane is then concentrated under vacuum and reduced pressure, and the tea soup is concentrated to a solid content of about 30% at a low temperature of about 50°C. Put the concentrated liquid into a forming vessel, carry out microwave vacuum low-temperature drying, control the drying time, and finally obtain the concentrated Pu'er tea essence or Pu'er tea essence powder.

[0042] The Pu'er tea paste block is obtained by adding 1% dextrin to 99% Pu'er tea essence concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com