3D printing metal-complex-structure supporting slurry, metal slurry and printing method

A complex structure, 3D printing technology, applied in the field of 3D printing technology and craftsmanship, can solve the problems of high price and disadvantage of metal materials, limit the freedom and complexity of printing modeling, and achieve good metal product quality, high strength and density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

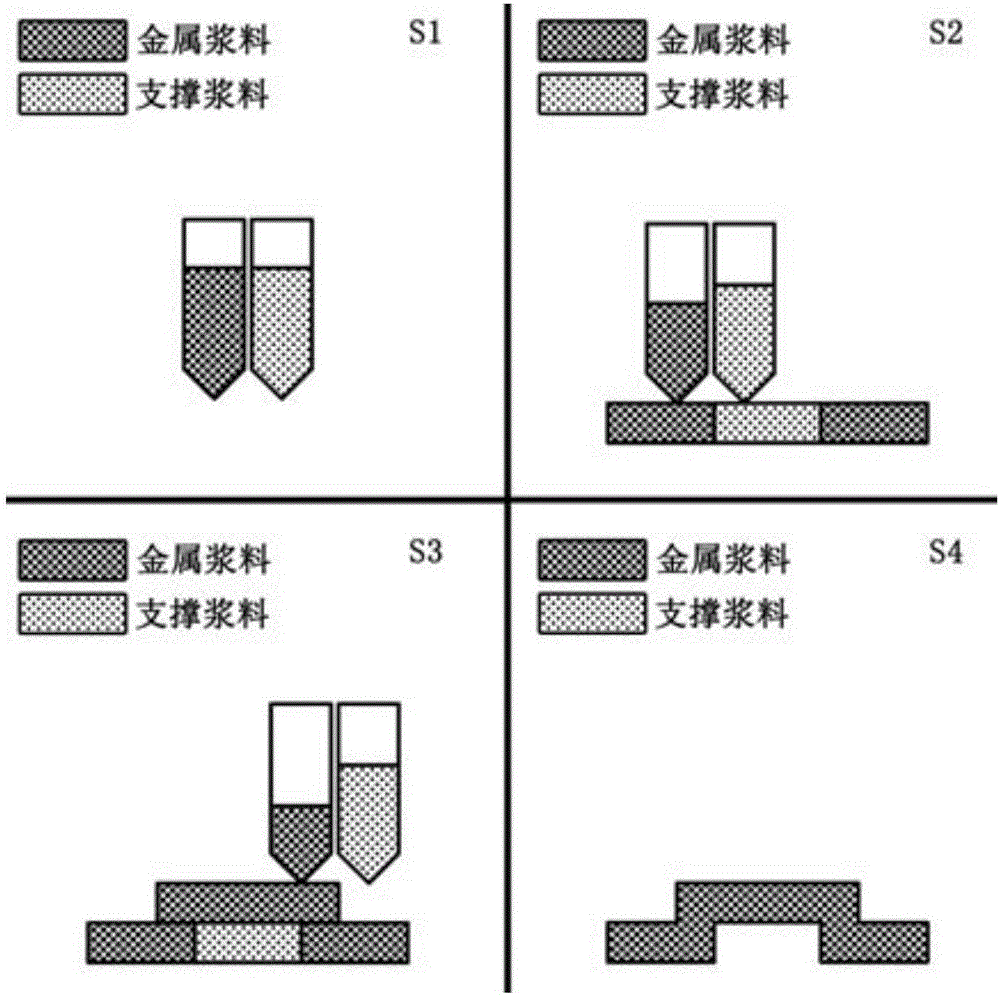

[0075] The present invention will be further described below in conjunction with drawings and embodiments.

[0076] The present invention provides a support slurry for 3D printing metal complex structures, and the support slurry adopts one of the following formulas:

[0077] (r1) Paraffin wax and carnauba wax with a mass and number ratio of 70±29:30±29;

[0078] (r2) paraffin wax, microcrystalline wax and methyl ethyl ketone with a ratio of parts by mass of 70±19:20±10:10±9;

[0079] (r3) Polypropylene, microcrystalline wax and stearic acid with a mass-number ratio of 57±40:32±30:11±10;

[0080] (r4) Paraffin wax, polyethylene, beeswax and stearic acid with a ratio of parts by mass of 43±21:23±10:33±10:2±1;

[0081] (r5) Paraffin wax, polypropylene, carnauba wax and stearic acid with a mass-number ratio of 63±34:20±19:15±14:2±1;

[0082] (r6) Paraffin wax, polyethylene, carnauba wax and stearic acid with a mass-number ratio of 63±34:20±19:15±14:2±1;

[0083] (r7) Paraffin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com