Method for preparing high-nitrogen steel through combination of pressurized induction and protective-atmosphere electro-slag remelting

A technology of pressure induction and protective atmosphere, applied in the field of high nitrogen steel smelting, can solve problems such as affecting the overall quality of steel, potential safety hazards, and complex pressurized slag furnace equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

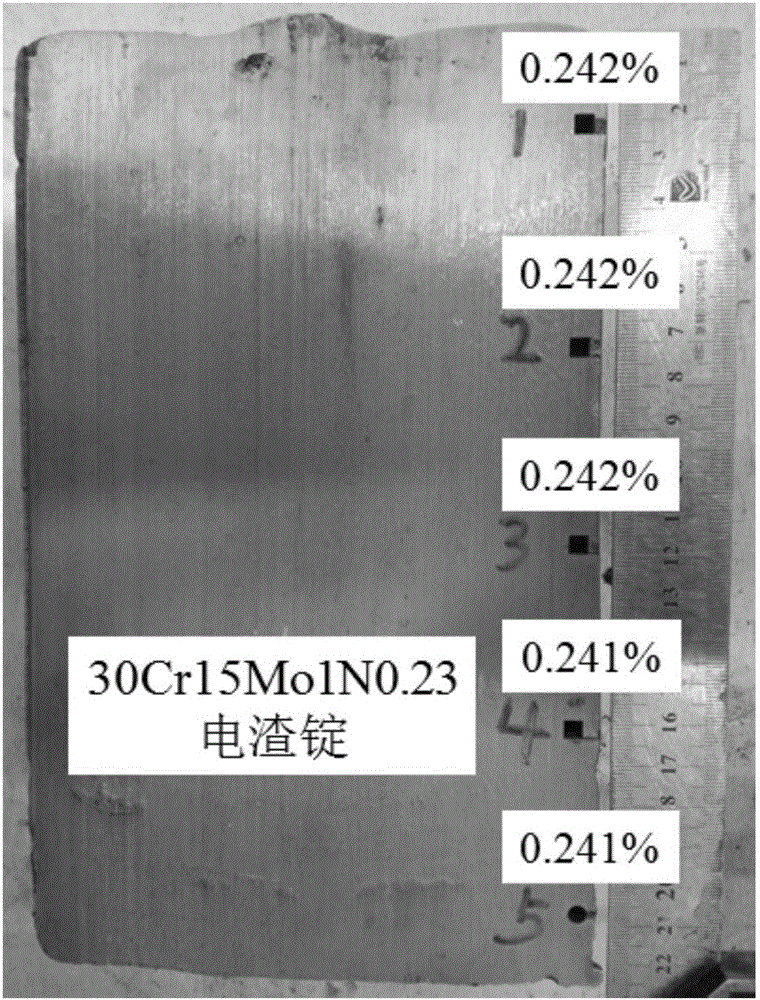

Embodiment 1

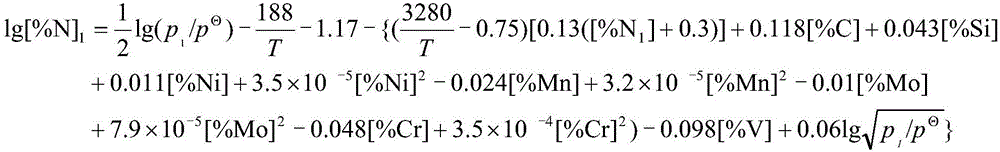

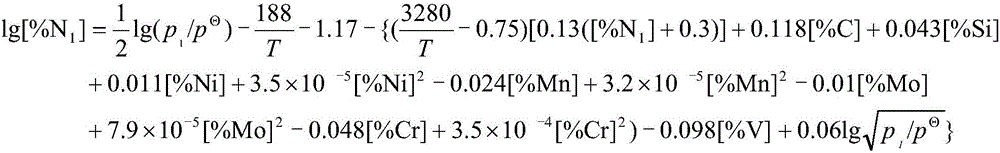

[0069] According to the nitrogen content in the target composition of high nitrogen steel, utilize formula ① to determine the nitrogen content of ingot; Described high nitrogen steel is high nitrogen martensitic steel, and its target composition is: C 0.3%, Mn 0.5 %, Cr 15%, Si 0.4%, Mo 1%, Ni 0.1%, N 0.25%, and the balance is Fe; the smelting pressure p of the pressure induction melting process is calculated by formula ② 1 ;Calculate casting pressure p by formula ③ 2 ;

[0070] Combining the composition of the target steel type, the composition of the smelting raw materials and the weight of the steel ingot to be smelted, calculate the weight of various raw materials required, and prepare the smelting raw materials;

[0071] Prepare raw materials for smelting; put industrial pure iron and chromium-containing components in the crucible of a pressurized induction furnace, and put molybdenum-containing components; put graphite and industrial silicon in the feeding bin, and put ...

Embodiment 2

[0086] Method is with embodiment 1, and difference is:

[0087] (1) The target composition of high nitrogen steel is: C 0.1%, Mn 5%, Cr 12%, Si 1%, Mo 3%, N 0.3%, Ni 1%, V 0.5%, and the balance is Fe;

[0088] Prepare raw materials for smelting; put industrial pure iron and chromium-containing components in the crucible of a pressurized induction furnace, put molybdenum-containing components and metallic nickel; put graphite and industrial silicon in the feeding bin, put vanadium-containing components, manganese-containing components composition and nickel-magnesium alloy; the chromium-containing composition is ferrochrome alloy, the molybdenum-containing composition is molybdenum-iron alloy, the manganese-containing composition is electrolytic manganese, and the vanadium-containing composition is vanadium-iron alloy;

[0089] (2) After all the smelting raw materials in the crucible of the pressurized induction furnace are melted, argon gas is introduced into the furnace to 30...

Embodiment 3

[0099] Method is with embodiment 1, and difference is:

[0100] (1) The target composition of high nitrogen steel is: C 0.6%, Cr 18%, Si 0.1%, N 0.35%, Ni2%, Mn 0.5%, V 1%, and the balance is Fe;

[0101] Prepare raw materials for smelting; put industrial pure iron and chromium-containing components in the crucible of the pressurized induction furnace, and put metal nickel; put graphite, industrial silicon and manganese-containing components in the feeding bin, and put vanadium-containing components and nickel-magnesium alloy; the chromium-containing component is metal chromium, the manganese-containing component is metal manganese, and the vanadium-containing component is metal vanadium;

[0102] (2) After all the smelting raw materials in the crucible of the pressurized induction furnace are melted, argon gas is introduced into the furnace to 50kPa, and 80% of the total mass of graphite is added from the feeding bin to the crucible; after adding the manganese-containing comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com