Method and device for manufacturing and forming metal material additives

A technology of additive manufacturing and metal materials, applied in the field of material processing, can solve problems such as research difficulties in micro-melting casting technology, achieve low processing cost, less internal defects, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

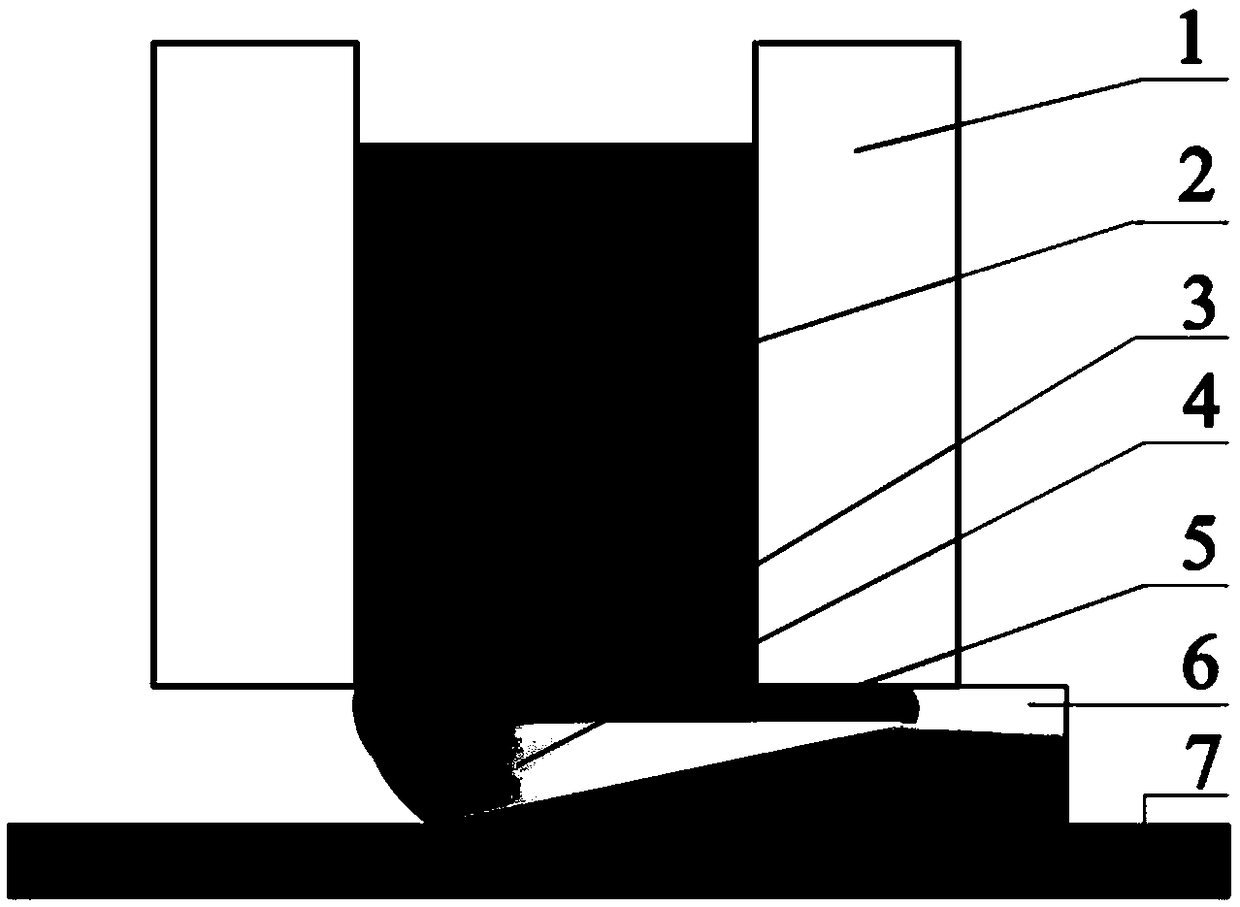

[0024] The metal material additive manufacturing molding method of the present invention comprises the following steps:

[0025] 1) Obtain the flowing liquid material from the smelting furnace and introduce it into the middle flow channel with the outlet below;

[0026] 2) By controlling the temperature and flow velocity of the liquid material, the liquid material entering the middle flow channel is gradually transformed into a fluid in which the liquid-solid two-phase coexists and its temperature is distributed with a high gradient and a low gradient;

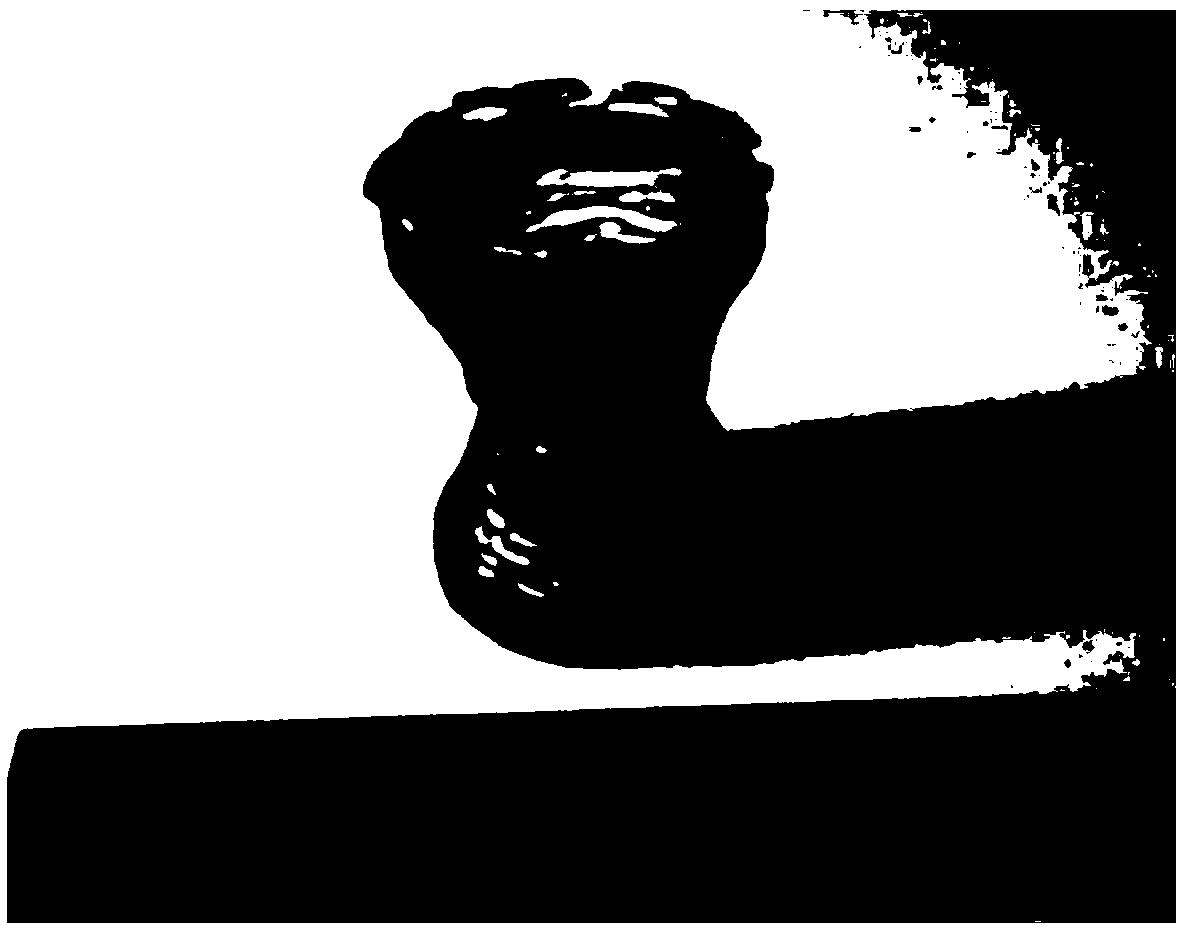

[0027] 3) Press the above-mentioned fluid material through the discharge port into the open forming area between its lower part and the substrate (crystallizer) or the accumulation layer attached to it, and use surface tension to constrain it in this space;

[0028] 4) While the fluid in contact with it is directional solidified in the direction of the incoming flow, the substrate (crystallizer) is moved parallel to the outlet...

Embodiment 2

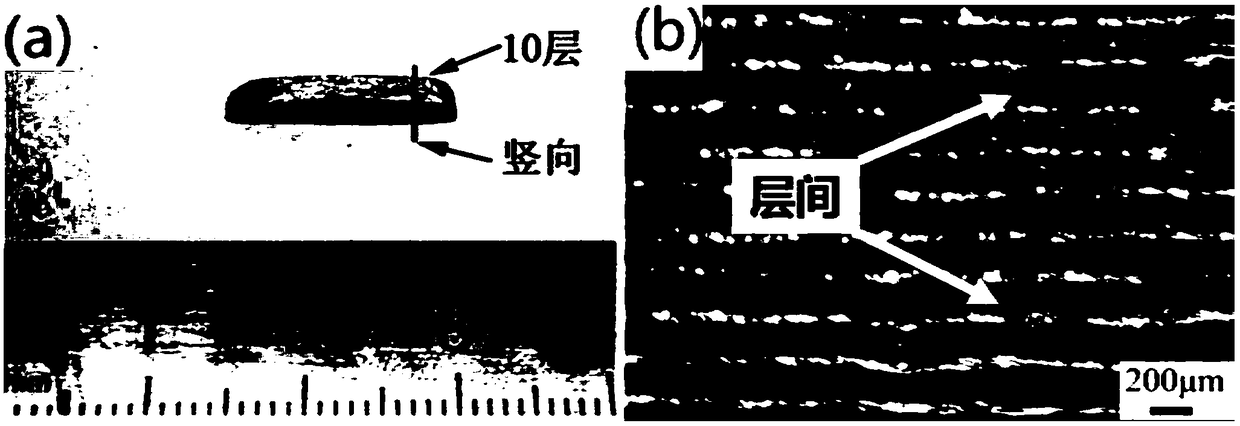

[0032] The metal material additive manufacturing molding method of this embodiment differs from Embodiment 1 in that: in order to prepare a metal member with a complex structure and a thickness perpendicular to the tangential direction greater than the thickness of the tangential single-layer structure, according to the performance of the member and the Accurate design requirements, design the slicing direction and slicing thickness of the three-dimensional digital slicing graphics of the parts to be manufactured, and set the movement track of the crystallizer, process and accumulate the above-mentioned solidified structure layer by layer and achieve a good interlayer interface Combination; substrate (crystallizer) The movement speed of the crystallizer is controlled within the range of no more than 0.5-20 cm / s.

[0033] The movement speed of the crystallizer is controlled within the range of no more than 0.5-20 cm / s. This speed range blocks and destroys the growth of primary d...

Embodiment 3

[0036] The metal material additive manufacturing forming method of this embodiment is different from Embodiment 1 and Embodiment 2 in that: the temperature and flow velocity of the liquid material are controlled to make the liquid metal material a fluid with better fluidity, and at the same time The fluid has a certain viscosity, which can make the fluid perfectly formed; for the non-eutectic alloy, control its solid phase ratio to not exceed 35%; for the eutectic alloy, control the fluid at the outlet to have a certain fluidity.

[0037] In this way, the metal fluid material required for the additive manufacturing of metal materials is prepared. Usually, the semi-solid metal melt has a certain viscosity and fluidity, and the alloy raw material of the metal material additive manufacturing forming method of the present invention is based on the semi-solid raw material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com