Excellent-demoulding-performance high-wear-resistant wet-method polyurethane resin used for labour protection gloves, and preparation method thereof

A technology of wet-process polyurethane and labor protection gloves, which is applied in the chemical field, can solve the problems of decreased wear resistance of gloves, and achieve the effects of improved wear resistance, low price, and small cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

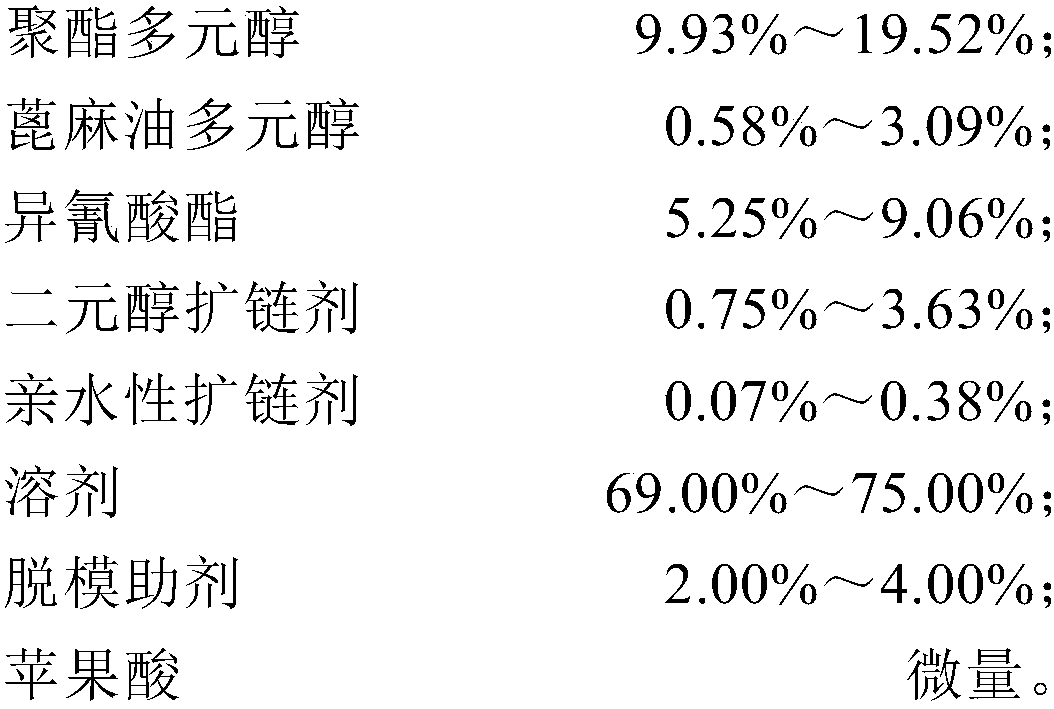

Method used

Image

Examples

Embodiment 1

[0027]

[0028]

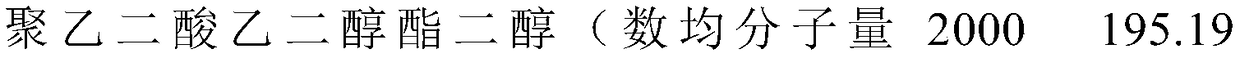

[0029] Put 195.19kg of polyethylene oxalate diol (number average molecular weight 2000g / mol) and 133.54kg of N,N-dimethylformamide into the reaction kettle, heat up to 40-50°C, stir well and add 22.69 The reaction temperature of kg diphenylmethane diisocyanate is controlled at 65-85°C, and the reaction time is 1.5-2.5h. After the viscosity of the reaction liquid reaches 220-260Pa·s / 50°C, 220.91kg N,N-dimethylformamide is added 10.27kg of castor oil diol (number-average molecular weight 2000g / mol) and 11.04kg of ethylene glycol and 0.99kg of 2,2-dihydroxypropionic acid are put into after stirring evenly, and 48.10kg of xylene methane is put into 48.10kg of xylene after mixing and reacting for 30-45min For diisocyanate, the reaction temperature is controlled at 65-85°C. During the reaction, the remaining MDI and the remaining N,N-dimethylformamide in the formula are continuously added until the final viscosity is 300-350Pa·s at 25°C. A small amount of mal...

Embodiment 2

[0031]

[0032] Put 174.84kg of polybutylene oxalate diol (number average molecular weight 2000g / mol) and 119.62kg of N,N-dimethylformamide into the reaction kettle, heat up to 40-50°C, stir well and add 20.32 The reaction temperature of kg diphenylmethane diisocyanate is controlled at 65-85°C, and the reaction time is 1.5-2.5h. After the viscosity of the reaction liquid reaches 220-260Pa·s / 50°C, 234.83kg N,N-dimethylformamide is added After stirring evenly, 30.86kg of castor oil diol (number-average molecular weight 1500g / mol) and 10.83kg of ethylene glycol and 0.98kg of 2,2-dihydroxypropionic acid were put into the mixture, and 50.65kg of xylene methane was put into the mixture for 30-45min. For diisocyanate, the reaction temperature is controlled at 65-85°C. During the reaction, the remaining MDI and the remaining N,N-dimethylformamide in the formula are continuously added until the final viscosity is 300-350Pa·s at 25°C. A small amount of malic acid terminates the react...

Embodiment 3

[0034]

[0035] Put 126.61kg of polyethylene oxalate diol (number average molecular weight 2000g / mol) and 86.62kg of N,N-dimethylformamide into the reaction kettle, heat up to 40-50°C, stir well and add 14.72 The reaction temperature of kg diphenylmethane diisocyanate is controlled at 65-85°C, and the reaction time is 1.5-2.5h. After the viscosity of the reaction solution reaches 160-200Pa·s / 50°C, 170.05kg N,N-dimethylformamide is added After stirring evenly, 22.34kg of castor oil diol (number-average molecular weight 2000g / mol) and 11.56kg of butanediol and 0.72kg of 2,2-dihydroxypropionic acid were put into it, and the xylene methane of 36.67kg was put into it after mixing evenly for 30-45min. For diisocyanate, the reaction temperature is controlled at 65-85°C. During the reaction, the remaining MDI and the remaining N,N-dimethylformamide in the formula are continuously added until the final viscosity is 220-280Pa·s at 25°C. A small amount of malic acid terminates the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com