Thermal-insulation baffle plate for liquid metal cooling and oriented solidification casting equipment

A liquid metal cooling and heat-insulating baffle technology is applied in the field of heat-insulating baffles, which can solve the problems of complicated manufacturing process, difficult to fix, fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

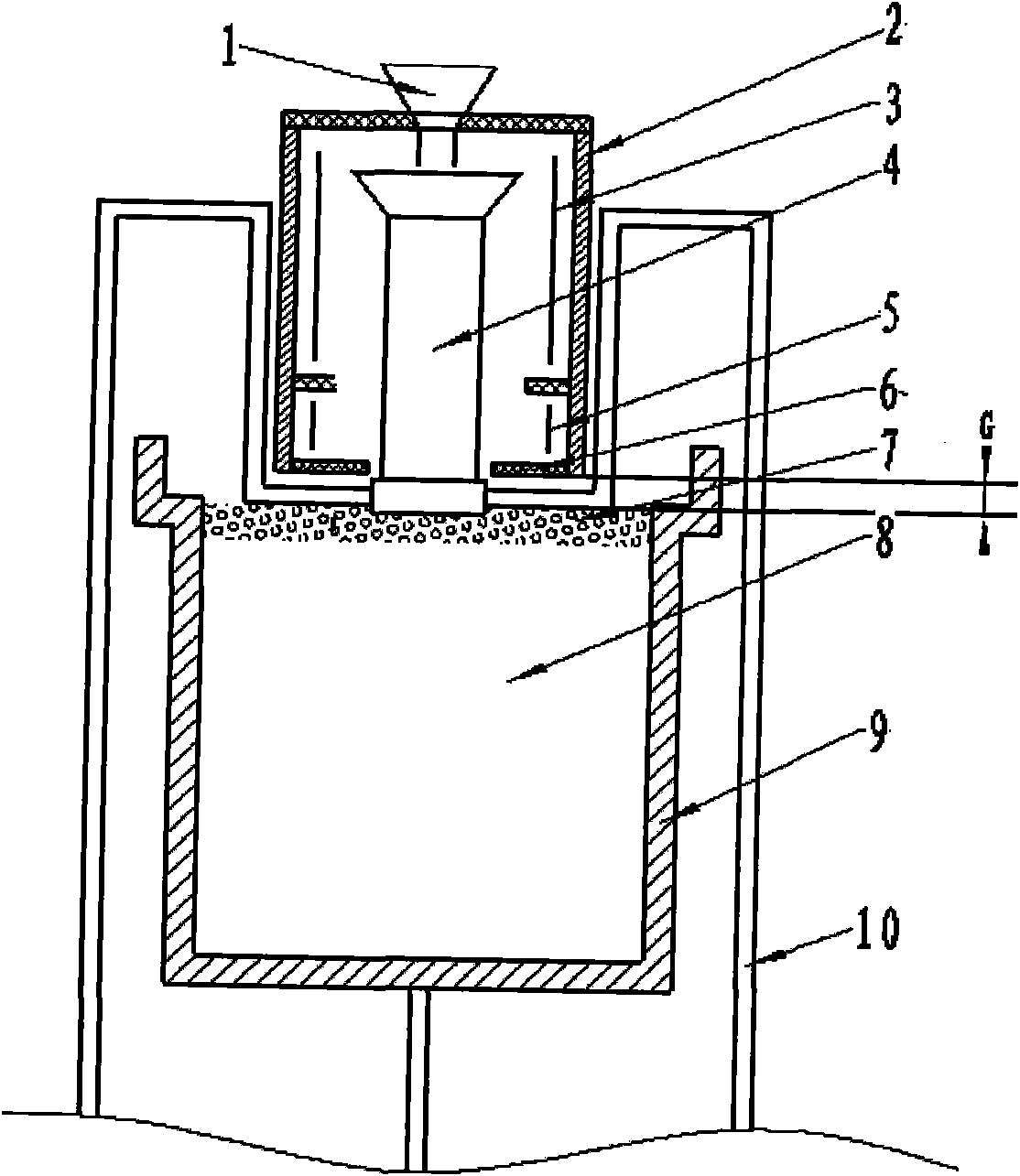

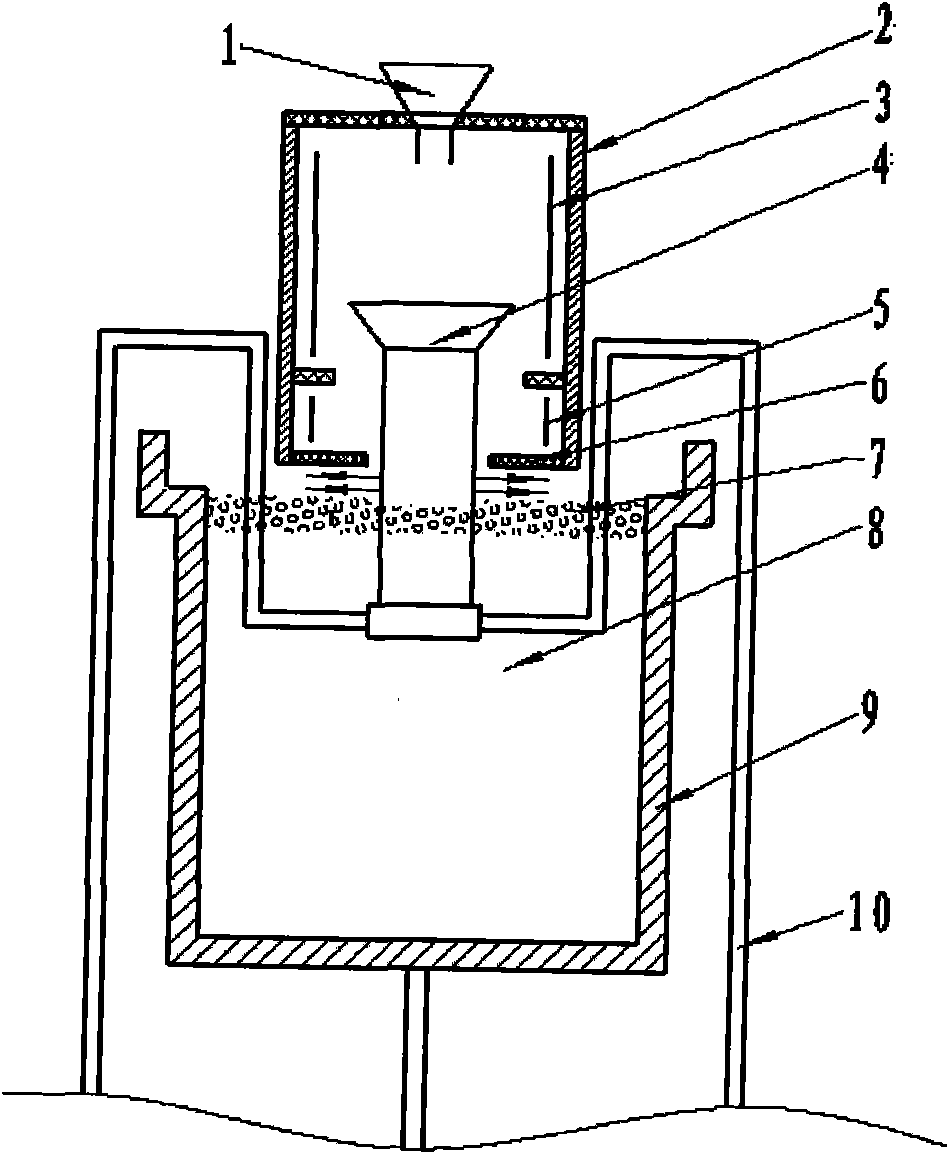

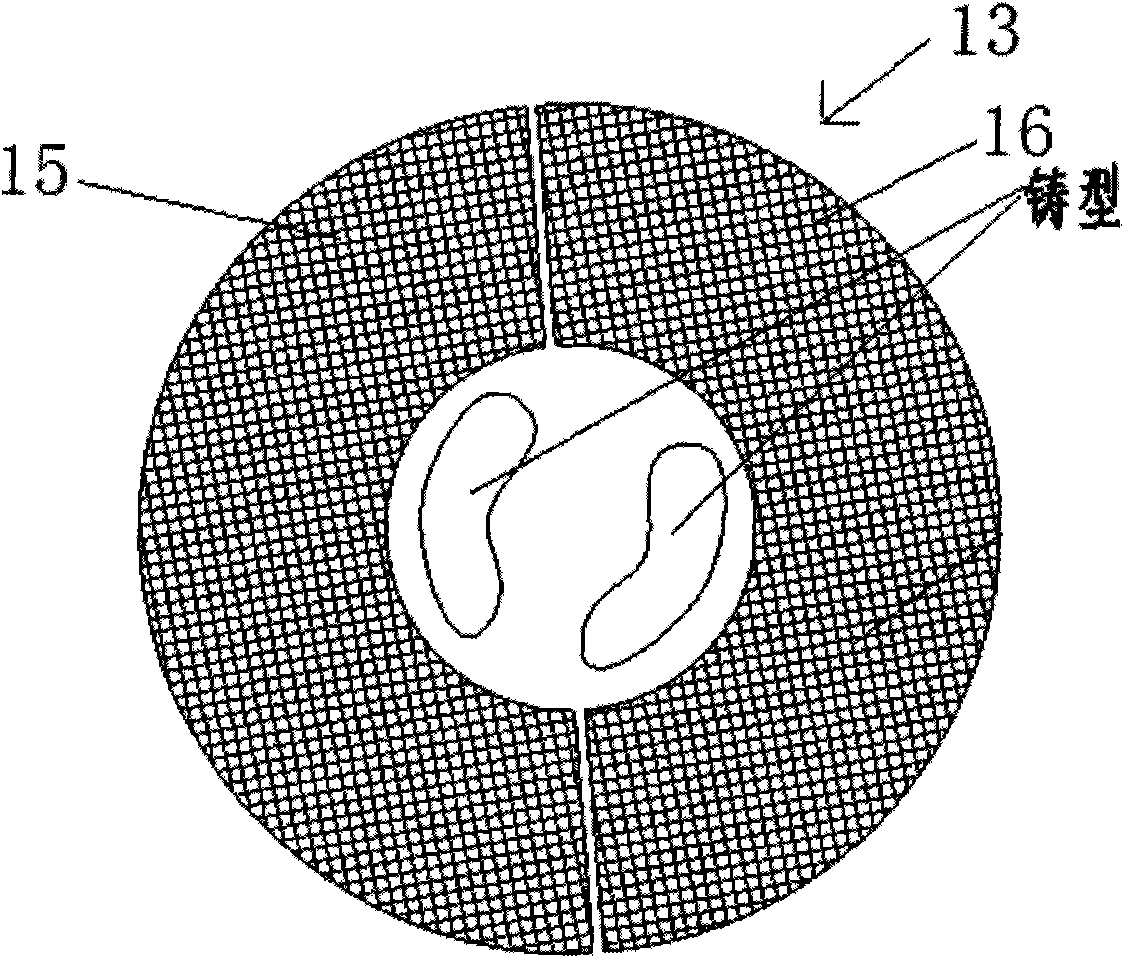

[0017] A heat insulation baffle for liquid metal cooling directional solidification casting equipment, which is an annular baffle 13, the annular baffle 13 can move left and right in the horizontal plane, and the annular baffle 13 is composed of a semi-annular baffle 15 and a semi-annular baffle 16 Composed of splicing, the semi-annular baffle 16 has the same structure as the semi-annular baffle 15, and is made of zirconia or silicon wafer sandwiched aluminum silicate fiber felt.

[0018] The principle of use of the heat insulation baffle of the present invention:

[0019] In the previous LMC process, a fixed heat insulation baffle was only installed at the bottom of the heating chamber holding furnace to prevent heat from being lost from the heating area to the cooling area, and a floating baffle was set on the surface of the liquid metal cooling medium to further prevent heat from the heating area to the cooling area. The region dissipates and increases the temperature gradi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com