Air-cooled semi-continuous casting system and method of high-activity alloy

A high-activity, semi-continuous technology, applied in the field of metallurgy, can solve problems such as easy splashing and volatilization, explosion at the casting site, toxicity of organic coolants, etc., and achieve the effects of promoting solidification and cooling, preventing leakage, and increasing the solidification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

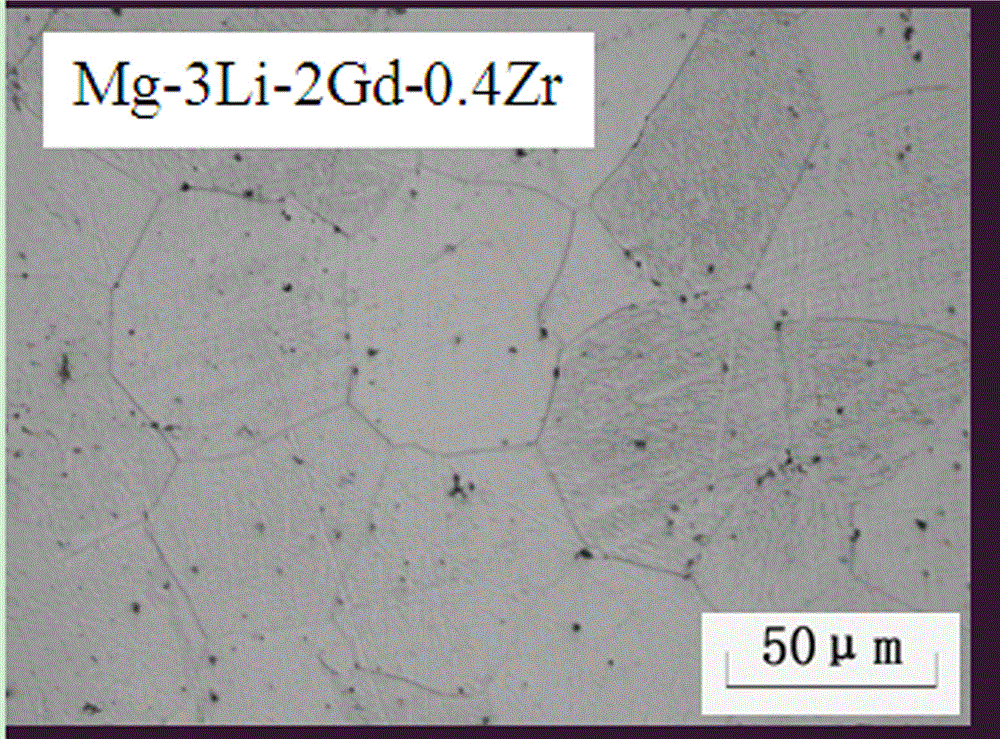

Embodiment 1

[0037] A high-activity alloy air-cooled semi-continuous casting system, the structure diagram is as follows figure 1 As shown, it includes a water-cooled crystallizer 1, an air injection device 2, a gas cooling device 3, an air tank 6 and a casting device, wherein the water-cooled crystallizer 1 is located above the air injection device 2; the air injection device 2 consists of an air injection ring 9, an air nozzle 8 and a guide The air nozzle 8 is arranged on the air injection ring 9, and the air deflector 10 is located directly below the air nozzle 8; the air injection device 2 is connected with the gas cooling device 3 and the gas tank 6 in turn.

[0038] In above-mentioned system, also be provided with gas compressor 5 and gas drier 4, as figure 2 As shown, the gas compressor 5 is connected to the gas dryer 4 through the air guide pipe 11, and the gas dryer 4 is connected to the gas storage tank 6; wherein the gas compressor is used to provide compressed gas for the seco...

Embodiment 2

[0049] A high-activity alloy air-cooled semi-continuous casting system, the structure of which is the same as that of Embodiment 1.

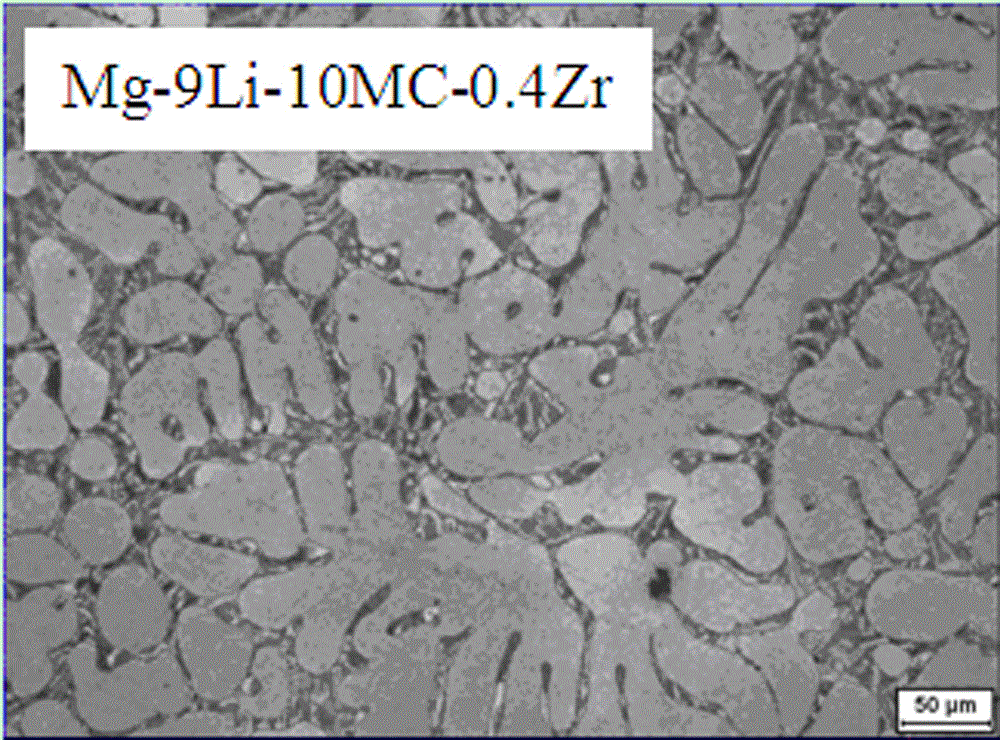

[0050] The air-cooled semi-continuous casting method of Mg-9Li-10MC-0.4Zr alloy adopts the above-mentioned system, and carries out according to the following process steps:

[0051] (1) First check the airtightness and patency of all pipelines in the above system, and adjust the angle between the nozzle angle and the horizontal direction to be 40°;

[0052] (2) Extend the dummy ingot into the water-cooled crystallizer, and the height of the probe into the water-cooled crystallizer is 10mm, remove the water and moisture on the inner wall of the crystallizer and the upper surface of the dummy ingot, and seal the dummy ingot and the crystallizer with a dry asbestos rope The gap between the inner walls; the smelted Mg-9Li-10MC-0.4Zr alloy melt is guided into the cavity formed by the crystallizer and the dummy ingot under the protection of a mixed ga...

Embodiment 3

[0056] A high-activity alloy air-cooled semi-continuous casting system, the structure of which is the same as that of Embodiment 1.

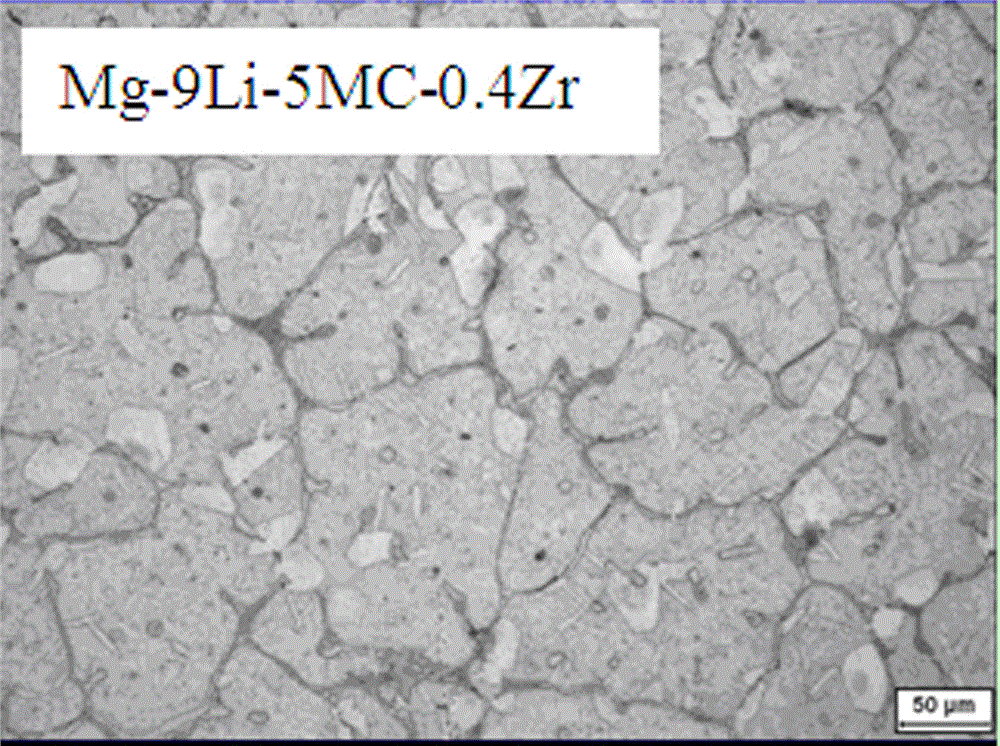

[0057] The air-cooled semi-continuous casting method of Mg-9Li-5MC-0.4Zr alloy adopts the above-mentioned system, and carries out according to the following process steps:

[0058] (1) First check the airtightness and patency of all pipelines in the above system, and adjust the angle between the nozzle angle and the horizontal direction to 60°;

[0059] (2) Extend the dummy ingot into the water-cooled crystallizer, and the height of the probe into the water-cooled crystallizer is 8mm, remove the water and moisture on the inner wall of the crystallizer and the upper surface of the dummy ingot, and seal the dummy ingot and the crystallizer with a dry asbestos rope The gap between the inner walls; the smelted Mg-9Li-5MC-0.4Zr alloy melt is guided into the cavity formed by the crystallizer and the dummy ingot under the protection of a mixed gas of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com