Nano silicon dioxide and basalt fiber synergistically enhanced recycled concrete and preparation method thereof

A nano-silica, basalt fiber technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of low tensile strength, high brittleness, easy shrinkage, etc. The effect of dense structure and enhanced bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

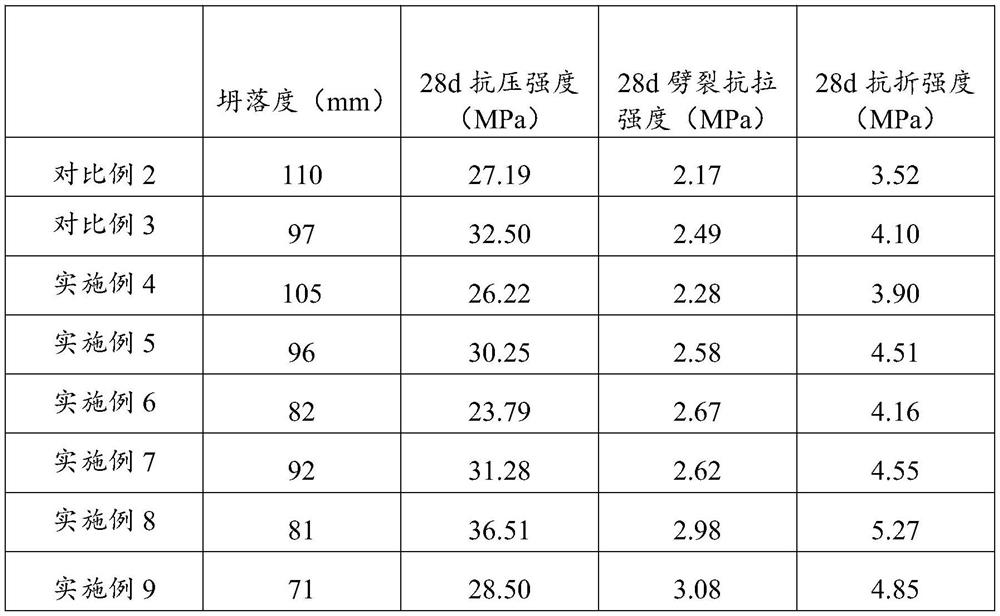

Examples

Embodiment 1

[0037] 1. Preparation

[0038] The waste concrete test blocks were crushed and screened to obtain recycled coarse aggregates, and coarse aggregates with a particle size range of 5 to 20 mm were selected, and then soaked in a nano-silica solution with a concentration of 1% for 48 hours, then removed and dried. Obtain modified concrete coarse aggregate.

[0039] 2. Performance test

[0040] According to "Inspection Method of Cement Mortar Strength (ISO Method)" (GB-T14685-2011), "Quality Standard and Inspection Method of Crushed Stone or Pebble for Ordinary Concrete" (JGJ53-92), the pressure of modified recycled coarse aggregate was measured. Crushing value, water absorption, apparent density are: 12.82%, 5.87%, 2659Kg / m 3 .

Embodiment 2

[0042] 1. Preparation

[0043] The waste concrete test block is crushed and sieved to obtain recycled coarse aggregate, and coarse aggregate with a particle size range of 5 to 20 mm is selected, and then soaked in a nano-silica solution with a concentration of 2% for 48 hours, then taken out and dried. Obtain modified concrete coarse aggregate.

[0044] 2. Performance test

[0045] According to "Inspection Method of Cement Mortar Strength (ISO Method)" (GB-T14685-2011), "Quality Standard and Inspection Method of Crushed Stone or Pebble for Ordinary Concrete" (JGJ53-92), the pressure of modified recycled coarse aggregate was measured. Crushing value, water absorption rate, apparent density are: 11.99%, 4.987%, 2667Kg / m 3 .

Embodiment 3

[0047] 1. Preparation

[0048] The waste concrete test block was crushed and sieved to obtain recycled coarse aggregate, and coarse aggregate with a particle size range of 5 to 20 mm was selected, and then soaked in a nano-silica solution with a concentration of 3% for 48 hours, then removed and dried. Obtain modified concrete coarse aggregate.

[0049] 2. Performance test

[0050] According to "Inspection Method of Cement Mortar Strength (ISO Method)" (GB-T14685-2011), "Quality Standard and Inspection Method of Crushed Stone or Pebble for Ordinary Concrete" (JGJ53-92), the pressure of modified recycled coarse aggregate was measured. Crushing value, water absorption, apparent density are: 11.42%, 4.95%, 2672Kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com