Counter-pressure casting process for ZL424 aluminum alloy castings

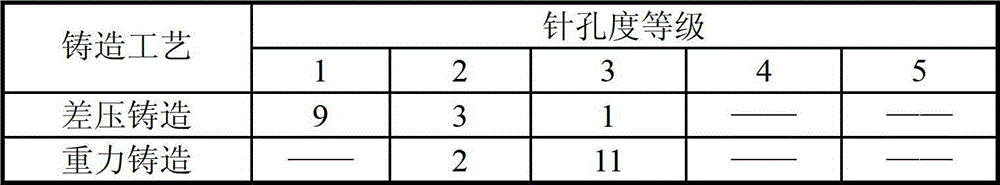

A ZL424, aluminum alloy casting technology, applied in the field of metal casting technology, can solve the problems of weak thickness sensitivity, poor casting process, low alloy fluidity, etc., to reduce pinhole defects, improve casting quality, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following describes the embodiment of the present invention in detail in conjunction with the data. It should be noted that the embodiment is descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0048] A ZL424 aluminum alloy casting differential pressure casting process, comprising the following steps:

[0049] ⑴. Casting alloy alloy ingredients

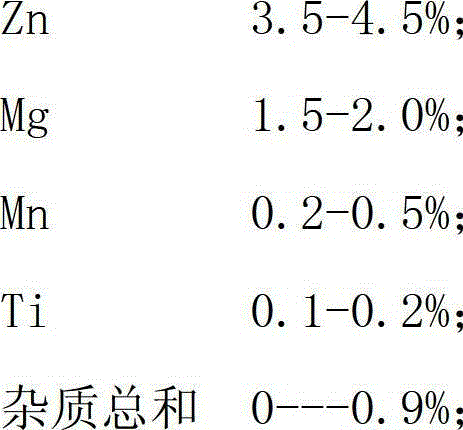

[0050] The batching of casting alloy comprises Zn, Mg, Mn, Ti and Al, and the weight percent of each batching is:

[0051]

[0052] The balance is Al.

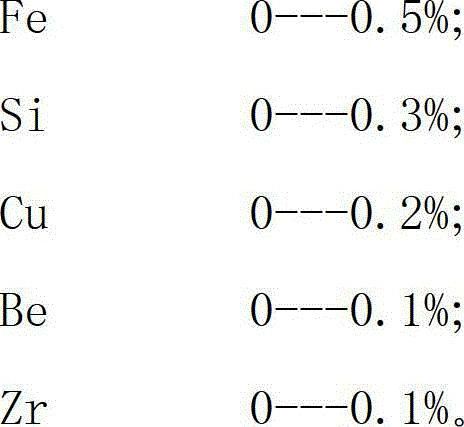

[0053] Above-mentioned impurity comprises Fe, Si, Cu, Be and Zr, and each impurity accounts for the percentage by weight of alloy batching gross weight as:

[0054]

[0055] ⑵. The alloy is smelted by secondary refining and intermediate purification

[0056] 1) Preparation of smelting tools: the main smelting equipment is an intermediate frequency induction furnace, commonly used smelting tools such as skimming spoons, samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com