Patents

Literature

35results about How to "Avoid exposure to oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glaze-crawling-proof protection coating for immersion type water gap slag line and preparation method of glaze-crawling-proof protection coating

The invention discloses a glaze-crawling-proof protection coating for an immersion type water gap slag line and a preparation method of the glaze-crawling-proof protection coating. The coating is prepared from a main material, water and dextrin; the main material is prepared from the following components in percentage by weight: 62 percent to 66 percent of tabular corundum, 15 percent to 17 percent of Suzhou clay, 3 percent to 5 percent of bentonite, 12 percent to 16 percent of active aluminum oxide and 0.5 percent to 1 percent of sodium silicate; the weight ratio of the water to the dextrin to the main material is (31 to 33):(0.6 to 0.8):100. The glaze-crawling-proof protection coating disclosed by the invention can be used for effectively preventing an anti-oxidization coating of the immersion type water gap slag line part from generating glaze crawling, so that the strength and anti-corrosion performance of the immersion type water gap slag line are improved, and the service life of an immersion type water gap can be prolonged for 2.5 hours to 3.5 hours.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

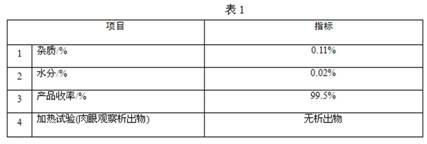

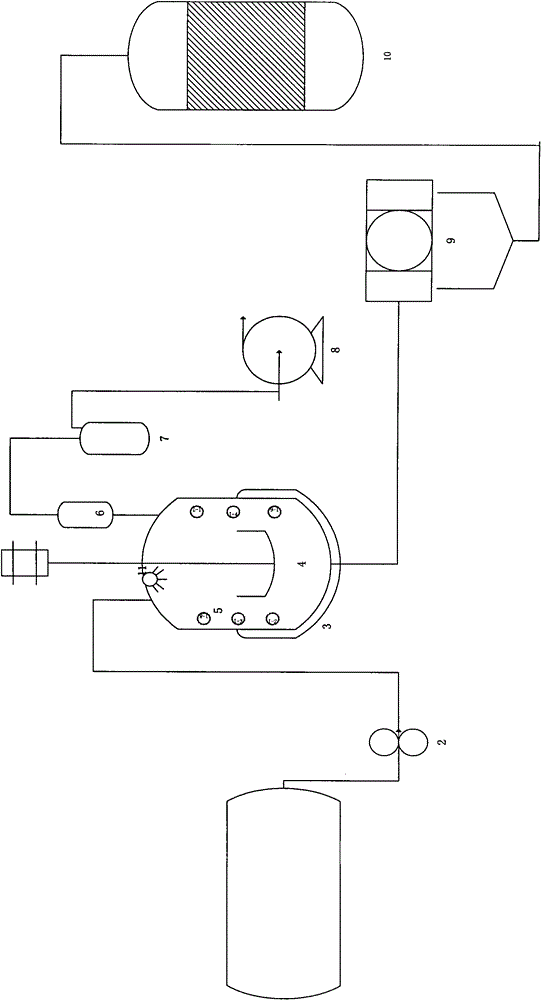

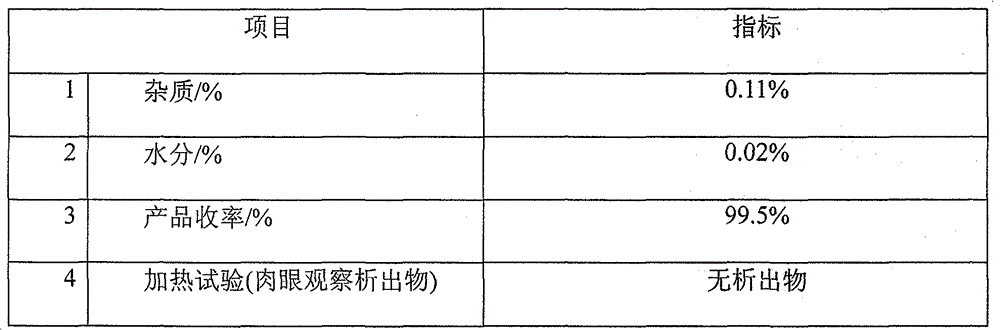

Novel dry-method degumming method for abandoned oil

InactiveCN102071103ASave waterSimple operating conditionsFatty-oils/fats refiningPhosphoric acidColloid

The invention mainly aims to solve the problems caused by degumming in the process of processing abandoned oil serving as raw materials. By dry-method degumming, the series of problems can be solved effectively. The method comprises the following steps of: adding a certain amount of acid (strong phosphoric acid: citric acid is 2:1) into a material system, and reacting at the temperature of 100 and 115 DEG C for 55 to 85 minutes, so that phospholipid in the abandoned oil serving as the raw materials is flocculated to form large granular flocculate; stirring a mixture, which serves as an adsorbent, of quantitative silica gel and carclazyte continuously for 50 and 80 minutes under the vacuum degree of between 0.080 and 0.098 Mpa, wherein the addition of the adsorbent is between 0.5 and 2.0 percent; and cooling the integral material system to a certain extent, filtering the hot material system, and filtering out colloid and part of pigments by adsorption. The process has a simple operational condition, does not generate oil foot, is less in pollution, can improve the yield of products by over 2 percent, achieves the discoloring effect while degumming, and improves the quality of oils obviously.

Owner:湖南欣林生物油脂工程技术有限公司

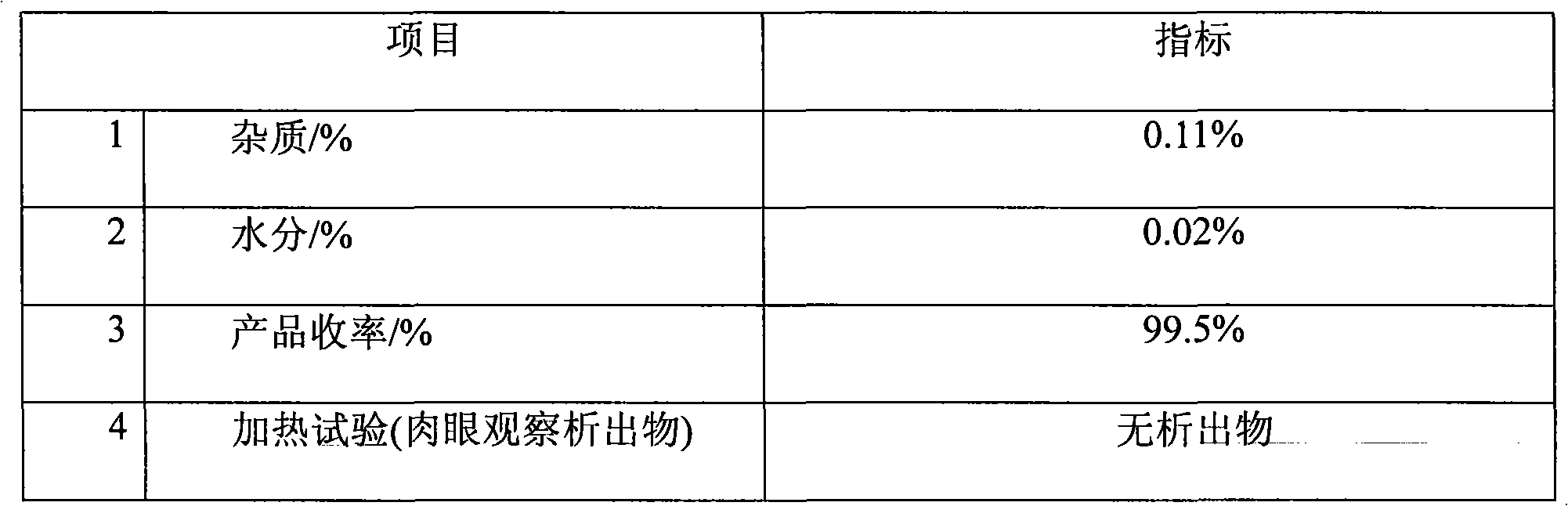

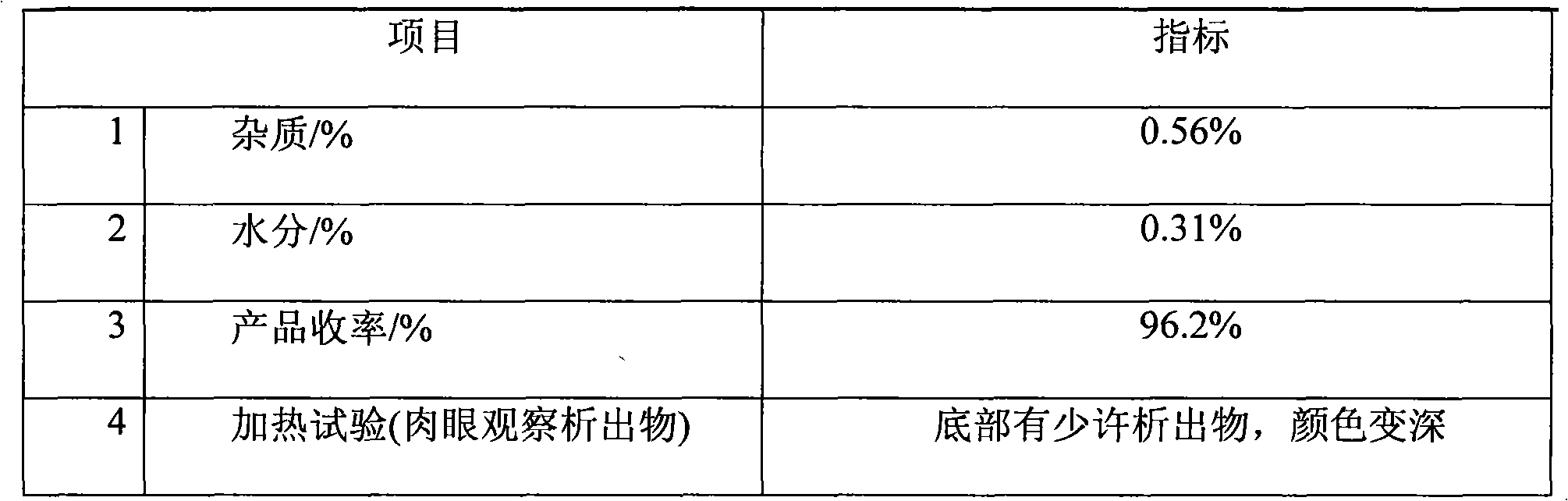

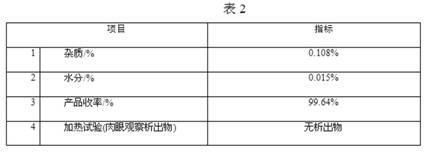

Dry degumming method of raw abandoned oil used for producing biodiesel

InactiveCN102304420AHas a decolorizing effectImprove qualityFatty oils/acids recovery from wasteFatty-oils/fats refiningBiodieselO-Phosphoric Acid

The invention discloses a dry degumming method of raw abandoned oil used for producing biodiesel. The method comprises steps that: (1) the abandoned oil is dehydrated; (2) a composite acid with a weight of 0.2 to 1.0% of that of the abandoned oil is added to the abandoned oil, wherein the composite acid is composed of strong phosphoric acid and citric acid according to a ratio of 2:1; the mixture is subject to a reaction for 50 to 90min under a reaction temperature of 100 to 120 DEG C, such that phospholipids form macro flocculating constituents; (3) a degumming absorbent with a mass of 0.5 to 2.0% of that of the raw materials is added to the raw materials; a vacuum degree is controlled at 0.080 to 0.098Mpa, a temperature is controlled at 110 to 130 DEG C, and the mixture is stirred for 30 to 60 min with a rate of 50 to 70r / min; (4) the mixture is processed through press filtration, and an obtained filtrate is a production raw material of biodiesel. The method provided by the invention has advantages of simple technology, high yield, and low production cost. Also, the method is energy saving and environment friendly.

Owner:HUNAN ACAD OF FORESTRY

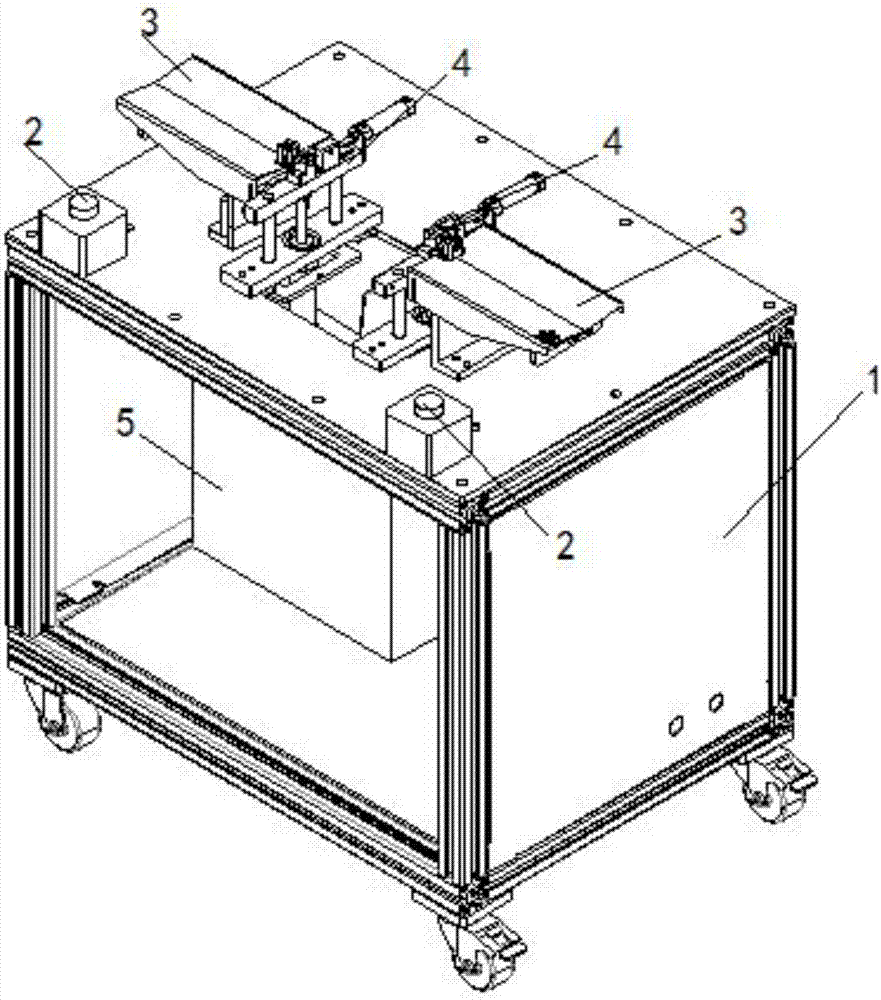

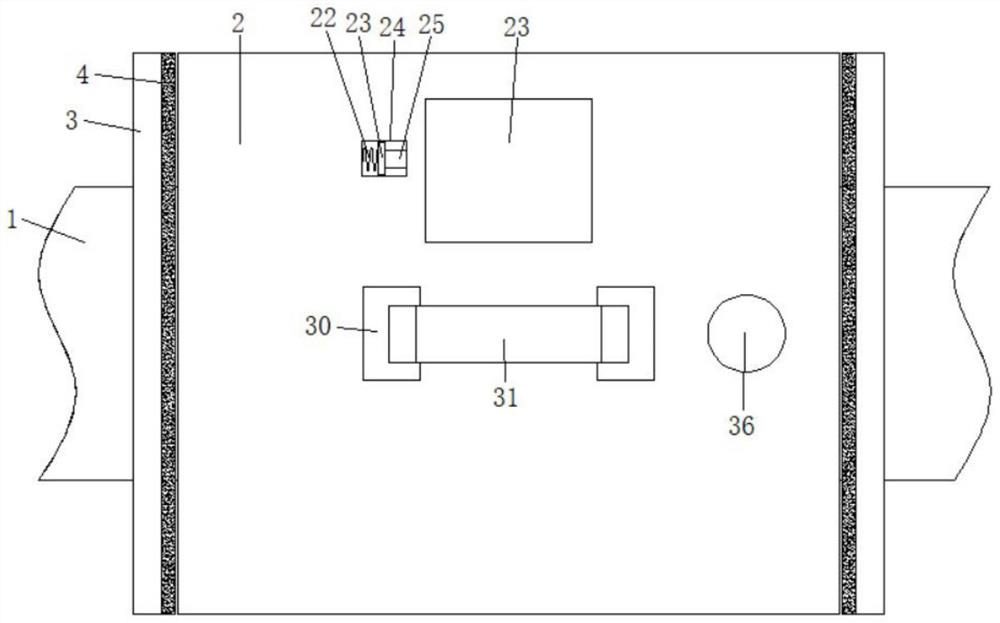

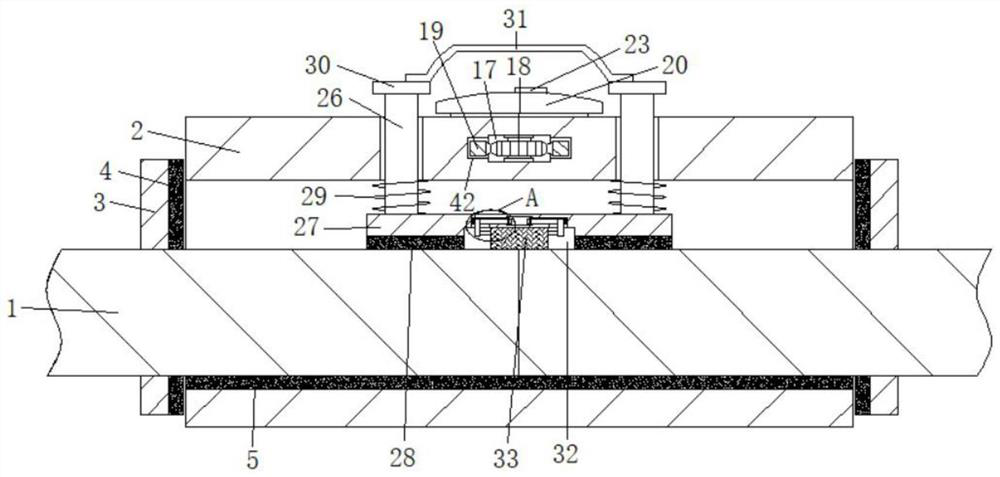

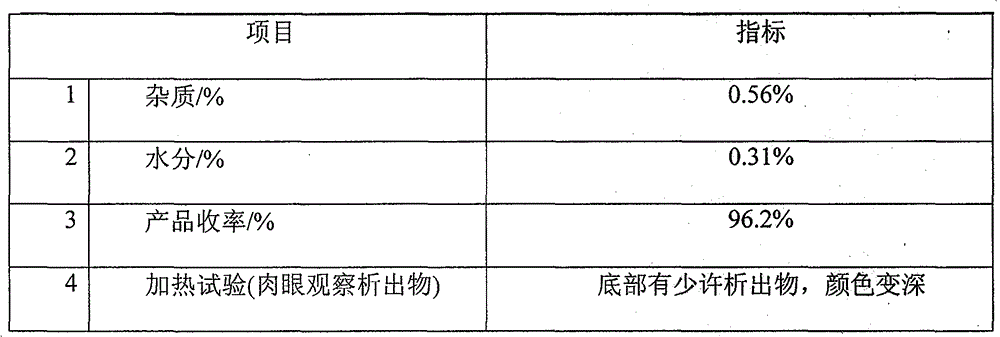

Novel seedling grafting device and grafting method thereof

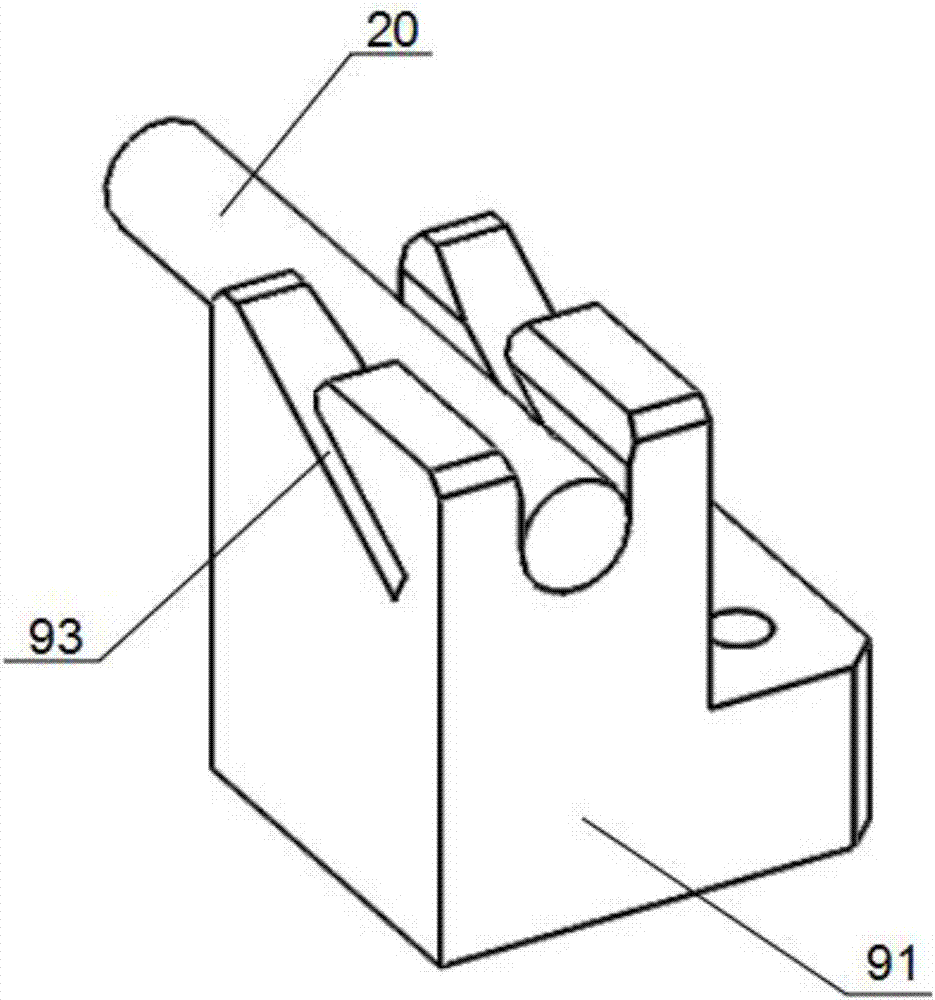

The invention provides a novel seedling grafting device and a grafting method thereof. The novel seedling grafting device comprises a rack, a clamping mechanism and a shearing mechanism, wherein the rack comprises a clamping mechanism mounting plate, the clamping mechanism comprises a clamping jaw air cylinder, a clamp head, a guide column and a seedling combining air cylinder, the clamping jaw air cylinder is installed on the clamping mechanism mounting plate, and drives the clamp head to conduct opening motion and closing motion, the seedling combining air cylinder is installed on the clamping mechanism mounting plate, and forward pushes the clamp head and the clamping jaw air cylinder, and the shearing mechanism comprises an abutting lifting air cylinder, a shearing air cylinder, a blade and a seedling placing groove; the shearing mechanism is arranged in front of the clamping mechanism, the abutting lifting air cylinder drives the shearing mechanism to move up and down, the seedling placing groove corresponds to the opening of the clamp head, the blade is arranged beside the seedling placing groove, and the shearing air cylinder drives the blade to move toward the seedling placing groove. According to the novel seedling grafting device, through the adoption of the clamping mechanism and the shearing mechanism, grafting can be completed within a short time, and the survival rate after grafting can be drastically increased.

Owner:SUZHOU XIAOYAN AUTOMATION EQUIP

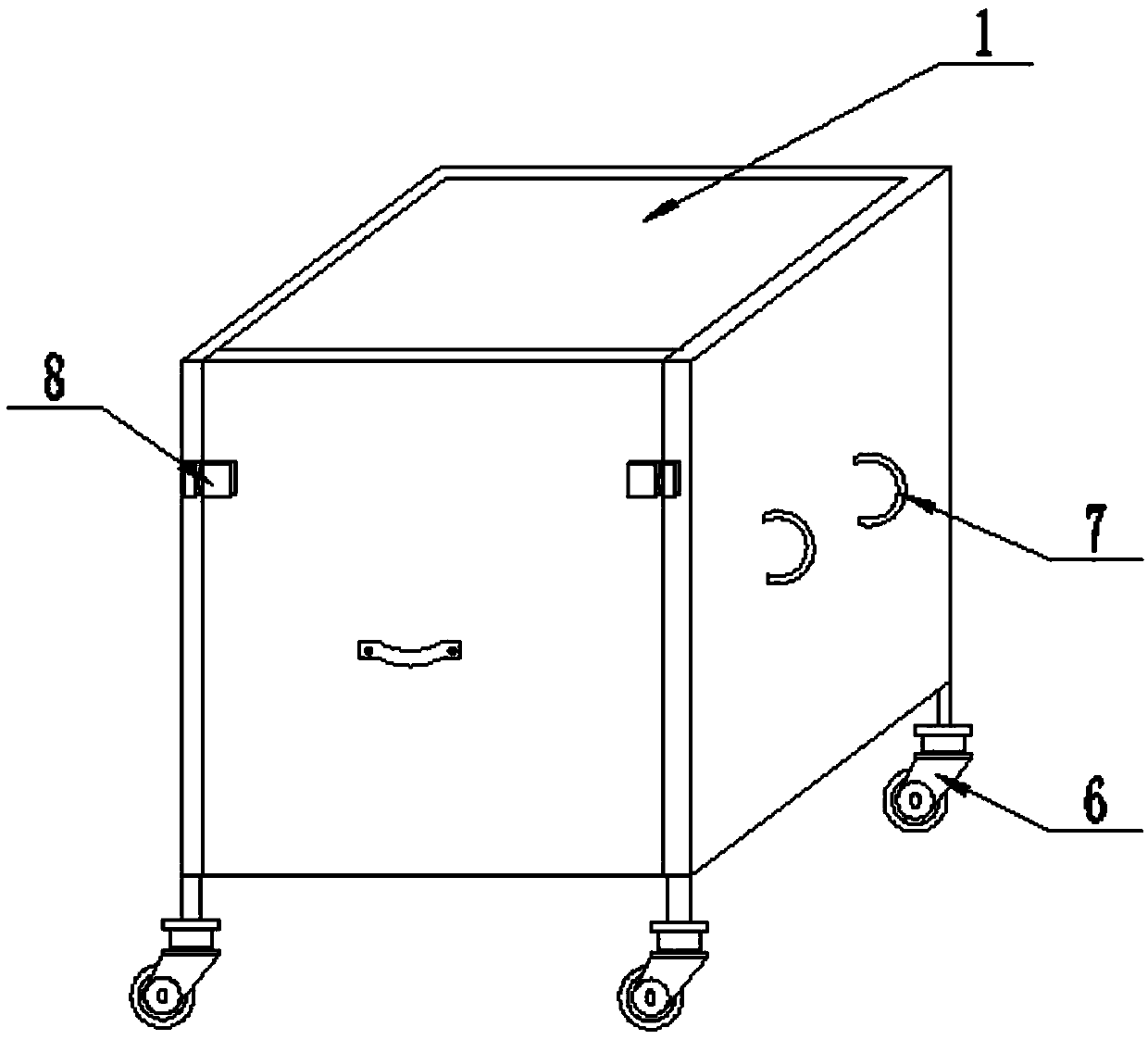

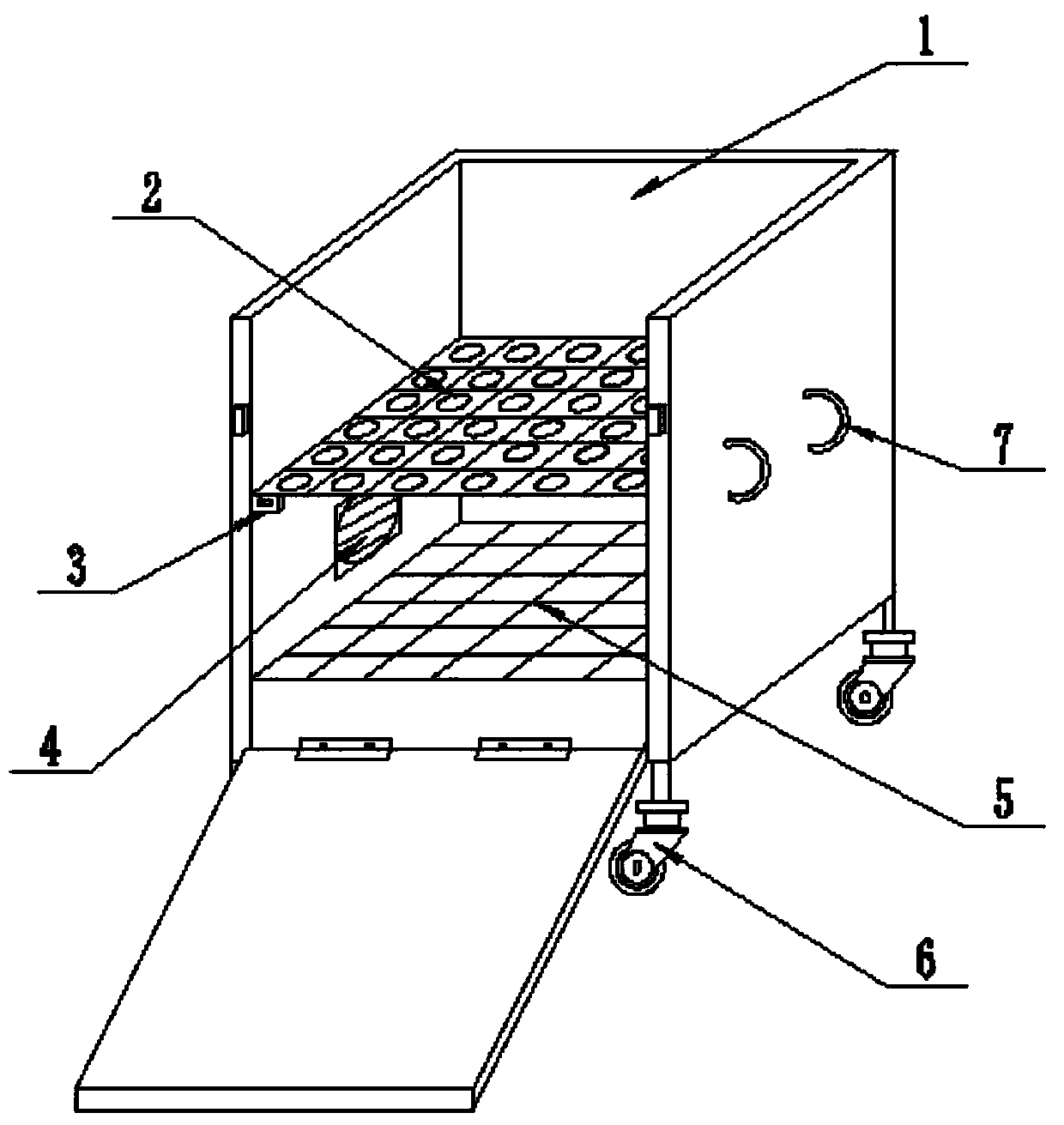

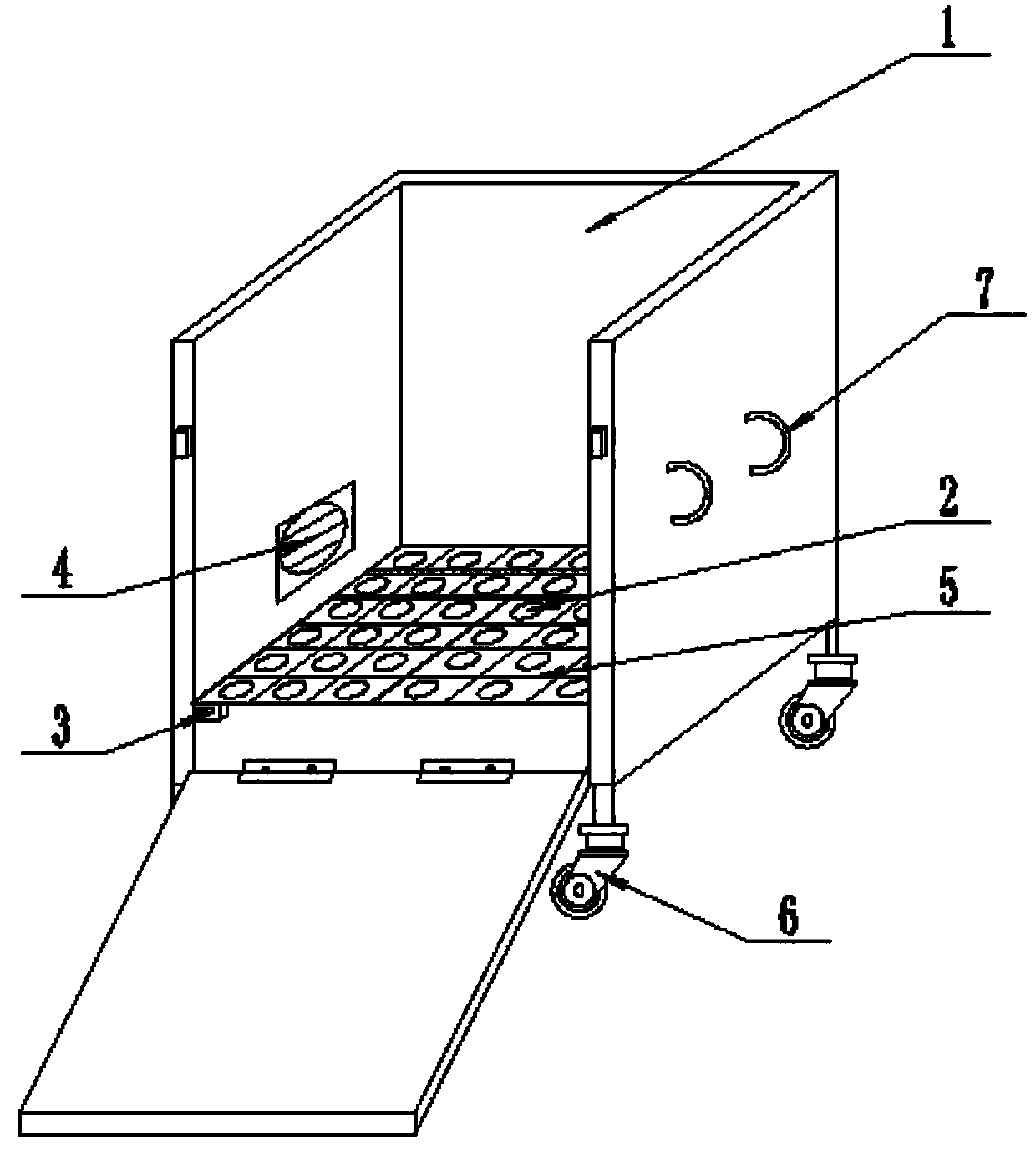

Multifunctional storage box with cellular board structure and used for storing copper tubes vertically

ActiveCN104192432AInsert firmlyLeave a gapContainers preventing decayContainer handlesChinese charactersStorage management

The invention discloses a multifunctional storage box with a cellular board structure and used for storing copper tubes vertically. The multifunctional storage box structurally comprises a box body, a pair of opposite side walls of the box body are opening-closing side walls hinged to a base, the other pair of side walls are fixed side walls fixedly connected with the base, the portion, close to the upper side, of the inside of the box body is provided with a cellular insertion plate used for allowing the copper tubes to be vertically inserted in, the portion, close to the lower side, of the inside of the box body is provided with an insertion plate with holes shaped like a Chinese character 'jing', the cellular insertion plate is connected with a counting sensor, and the box body is further provided with a dehumidifier. The multifunctional storage box with the cellular board structure and used for storing the copper tubes vertically can prevent oxidation and rust, has a counting function and facilitating storage management.

Owner:安徽金三环工程建设有限公司

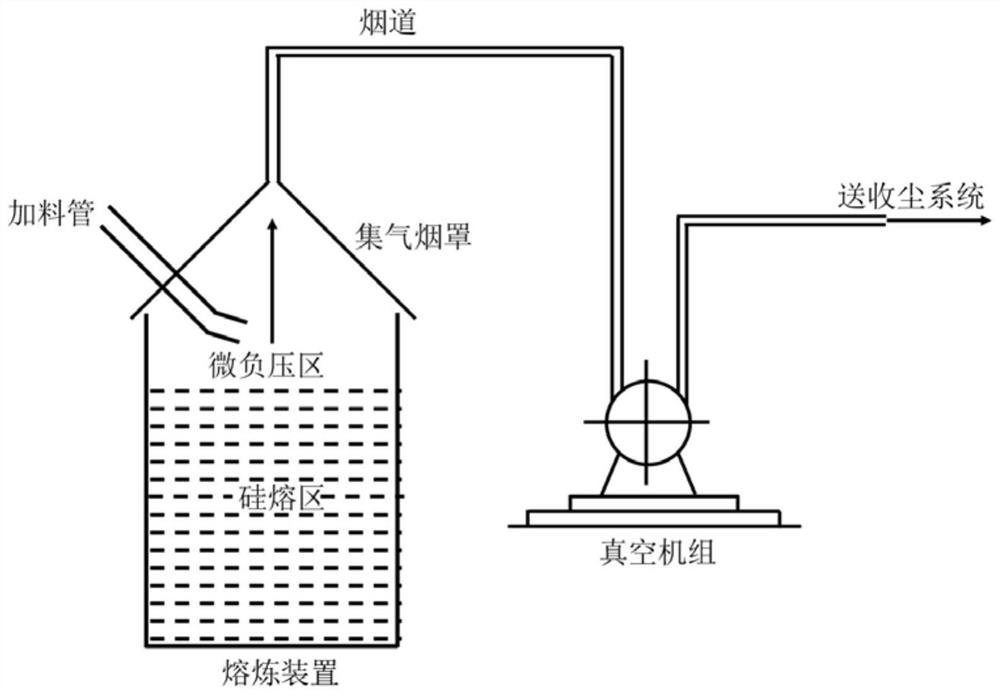

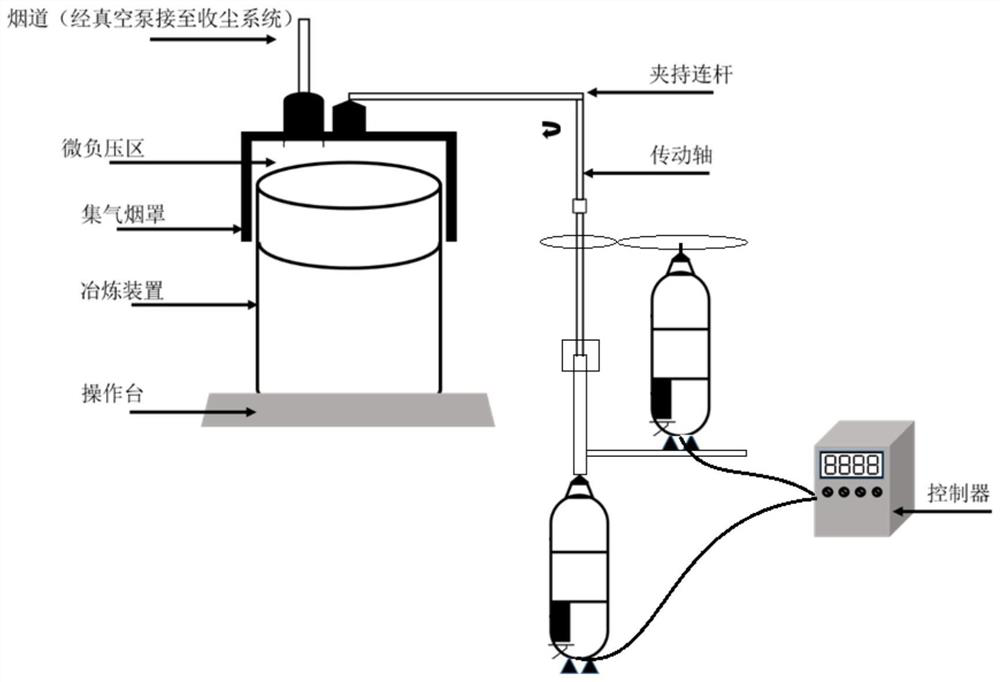

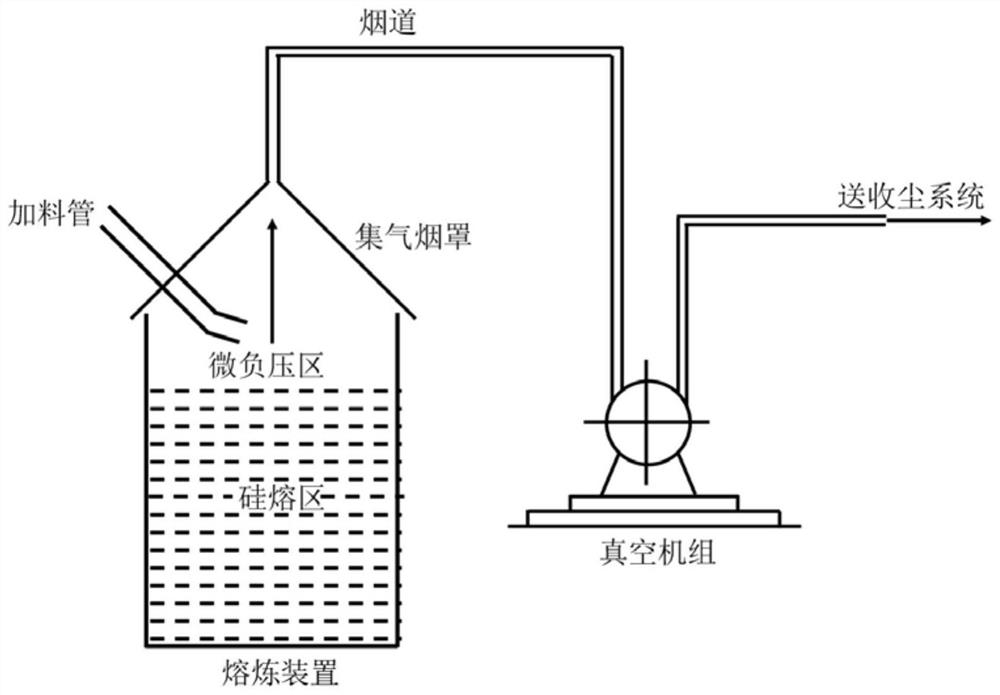

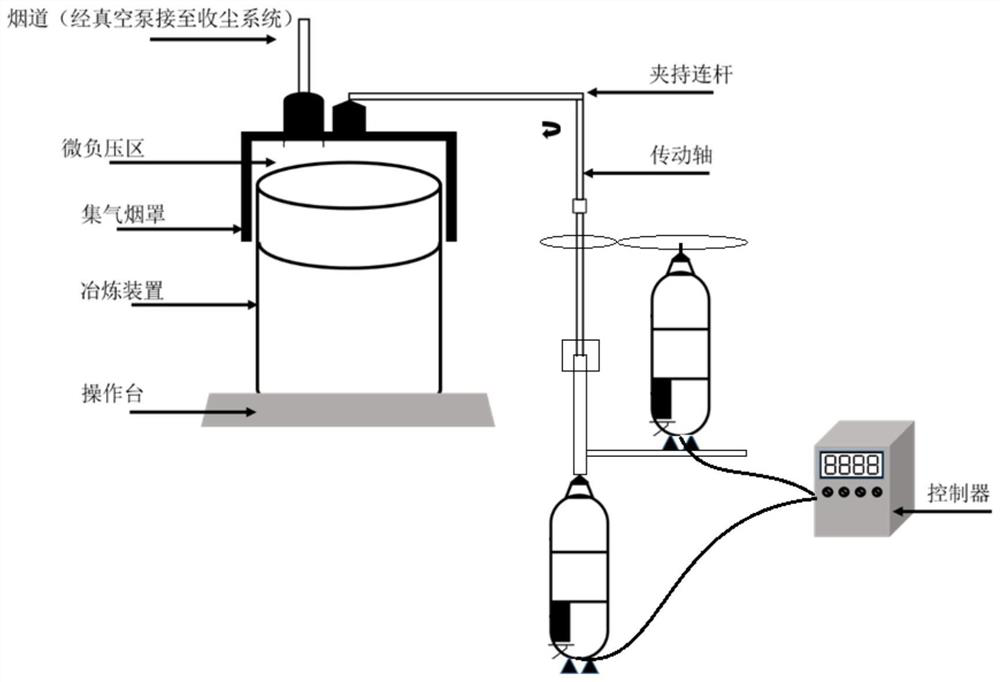

Method for smelting silicon wafer cutting waste under micro-negative pressure

ActiveCN111792647AHigh recovery ratePrevent oxidationSilicon compoundsRefining (metallurgy)Smelting process

The invention relates to a method for smelting silicon wafer cutting waste under micro-negative pressure, belonging to the technical field of silicon regeneration and recovery by pyrometallurgy of silicon wafer cutting waste. The invention aims to solve the problems that silicon powder is easy to oxidize in the smelting process and impurity removal efficiency is low in the smelting process due tothe existence of moisture in the pyrometallurgy silicon recovery process of silicon wafer cutting waste. According to the invention, a micro-negative pressure device is moved to a position over a smelting furnace opening, and a vacuum device of the micro-negative pressure device is started to enable silicon wafer cutting waste to undergo micro-negative pressure smelting, so oxidation loss of superfine silicon powder in the smelting process is avoided, volatile impurities in silicon are removed, and synchronous refining of silicon melt is achieved. According to the invention, a micro-negative pressure environment is created above the silicon melt, so smoke can be prevented from escaping in the silicon smelting process, and the environmental influence is reduced. The method is simple in equipment requirement, easy to operate, friendly to environment and suitable for large-scale industrial production.

Owner:KUNMING UNIV OF SCI & TECH

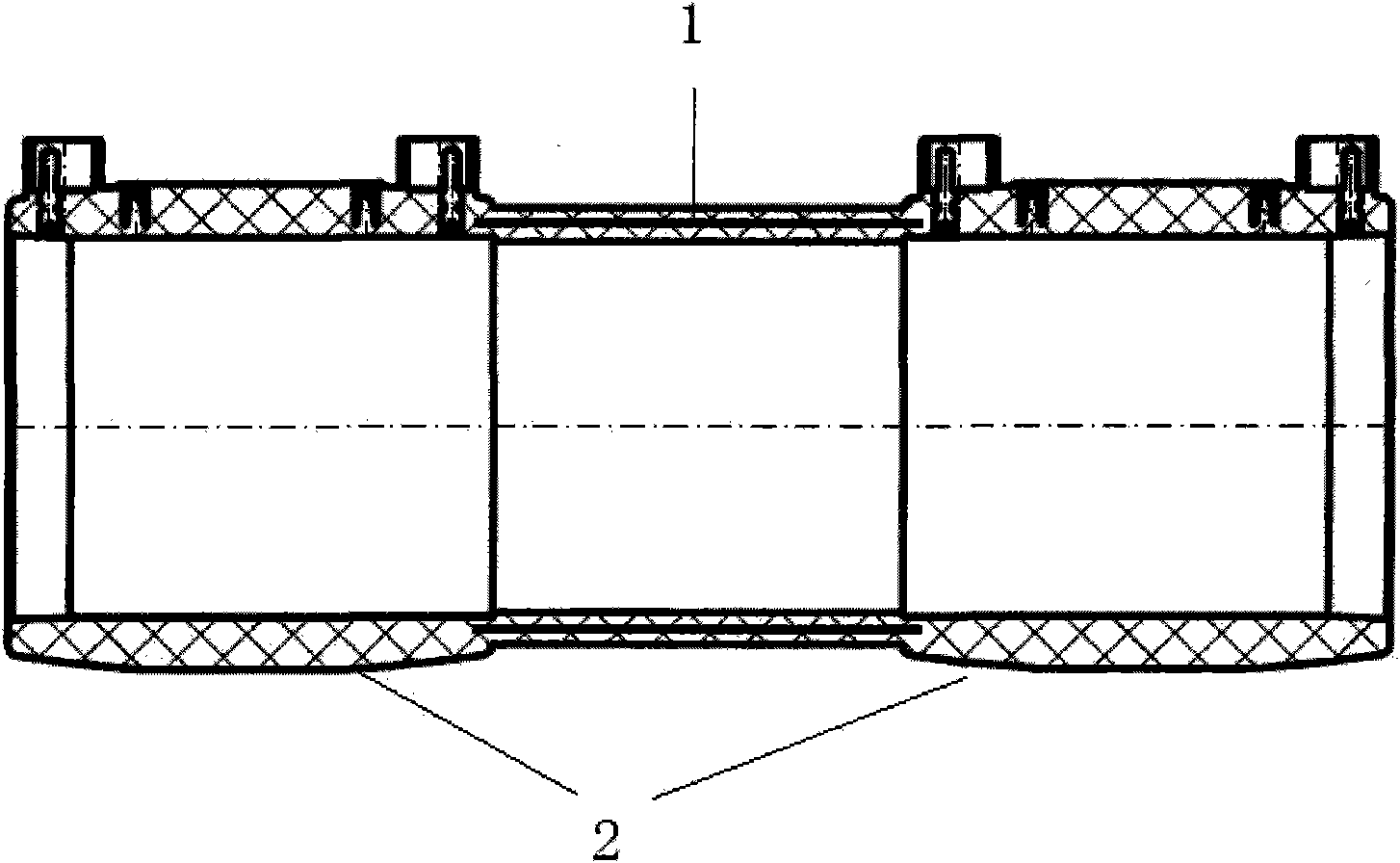

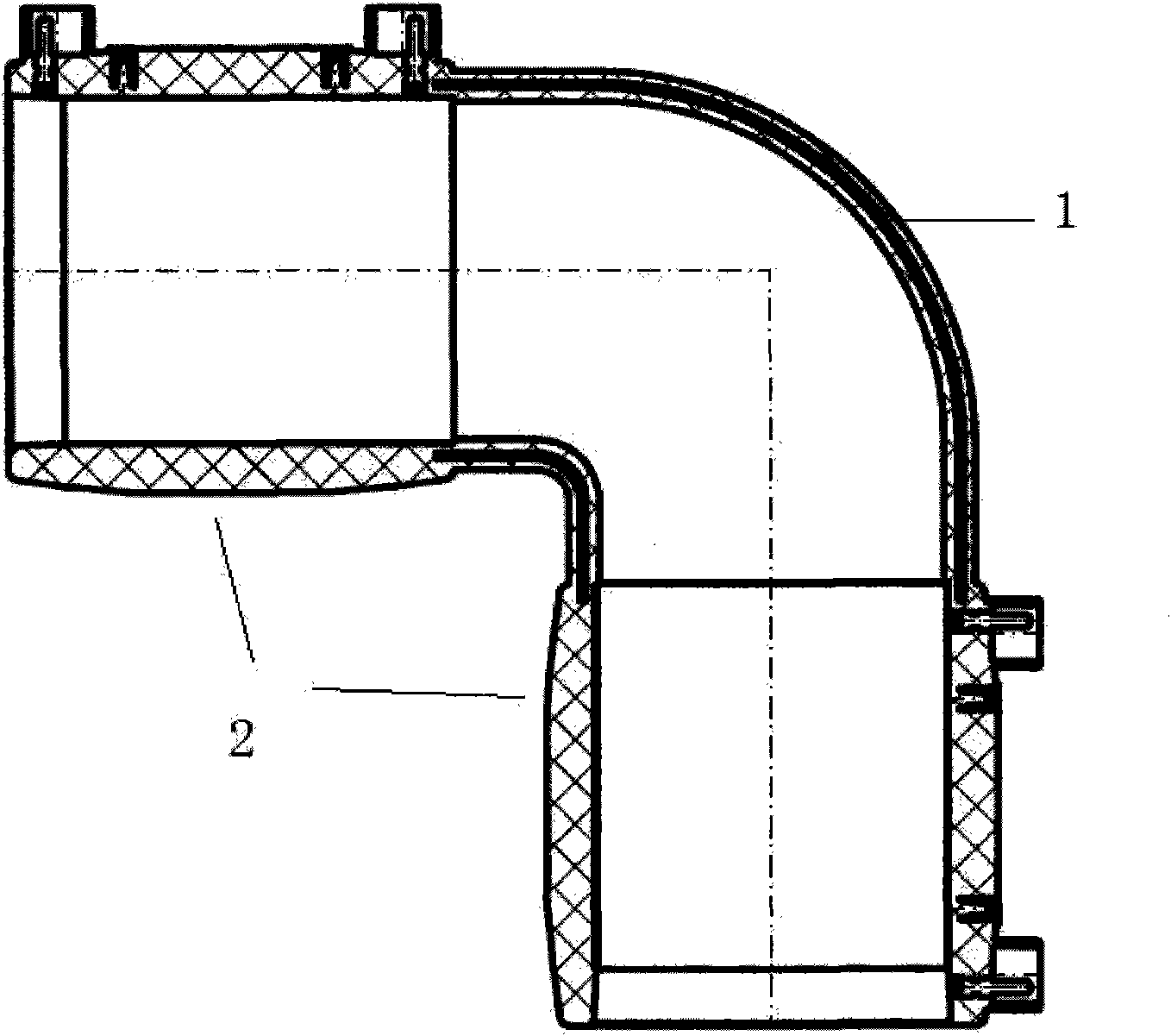

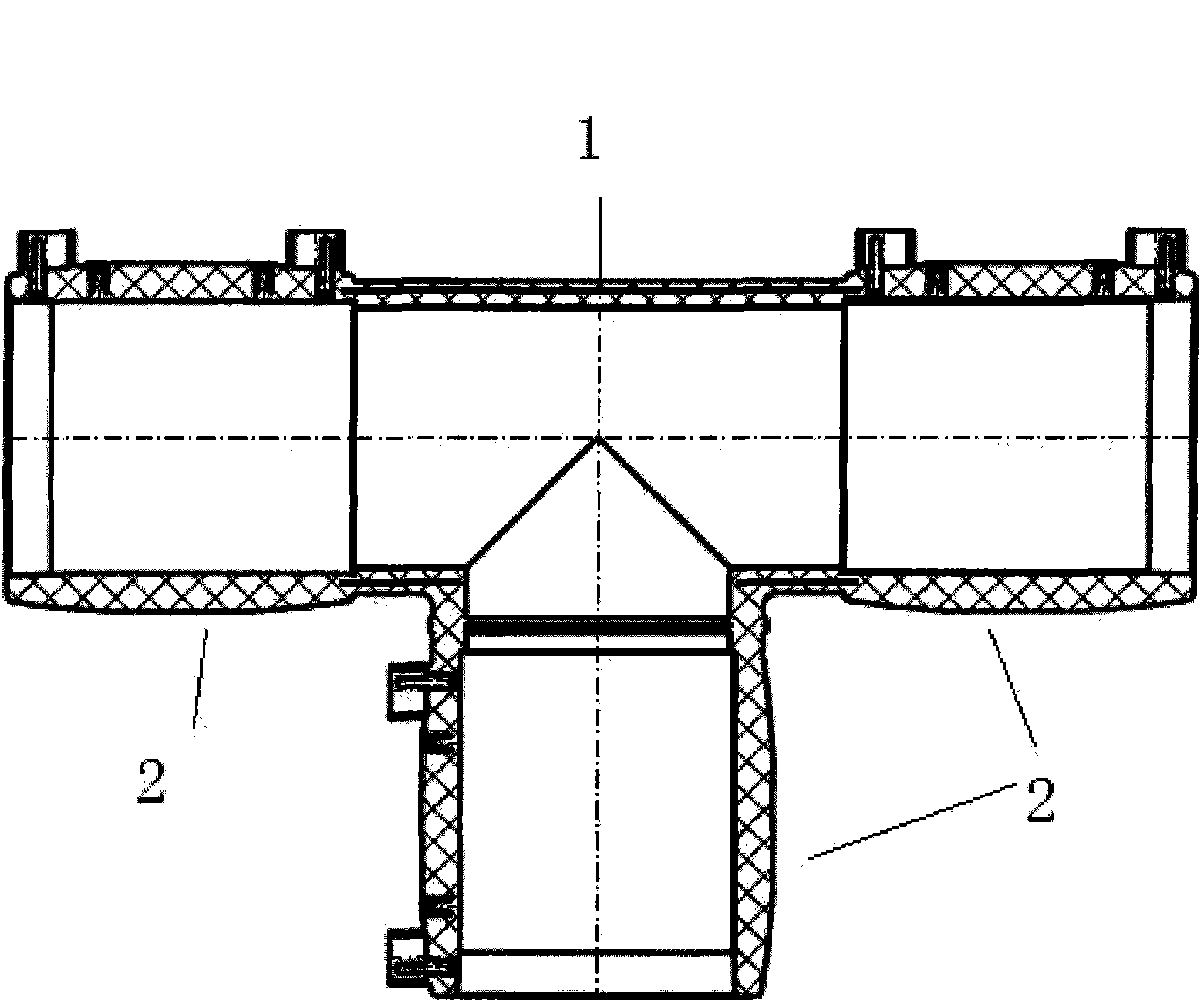

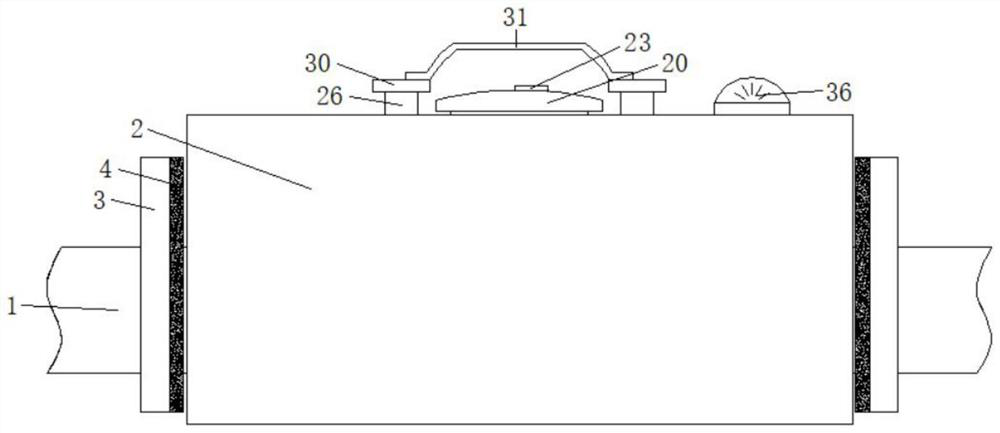

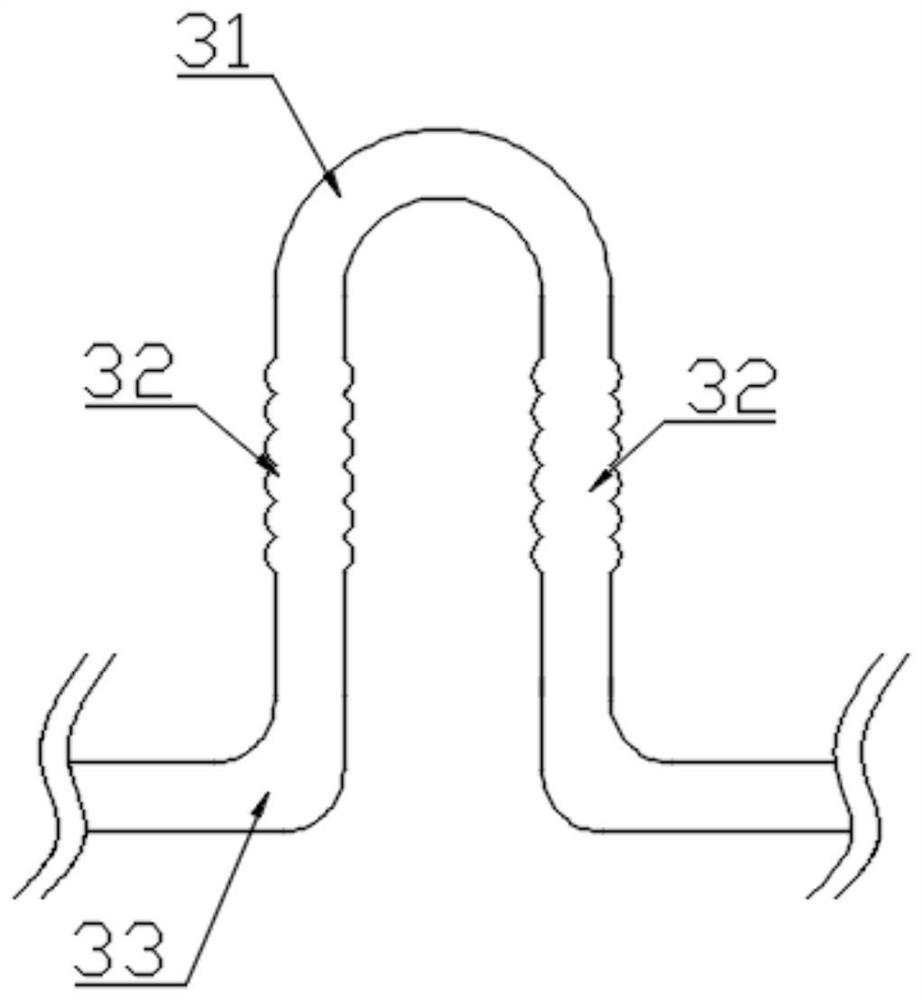

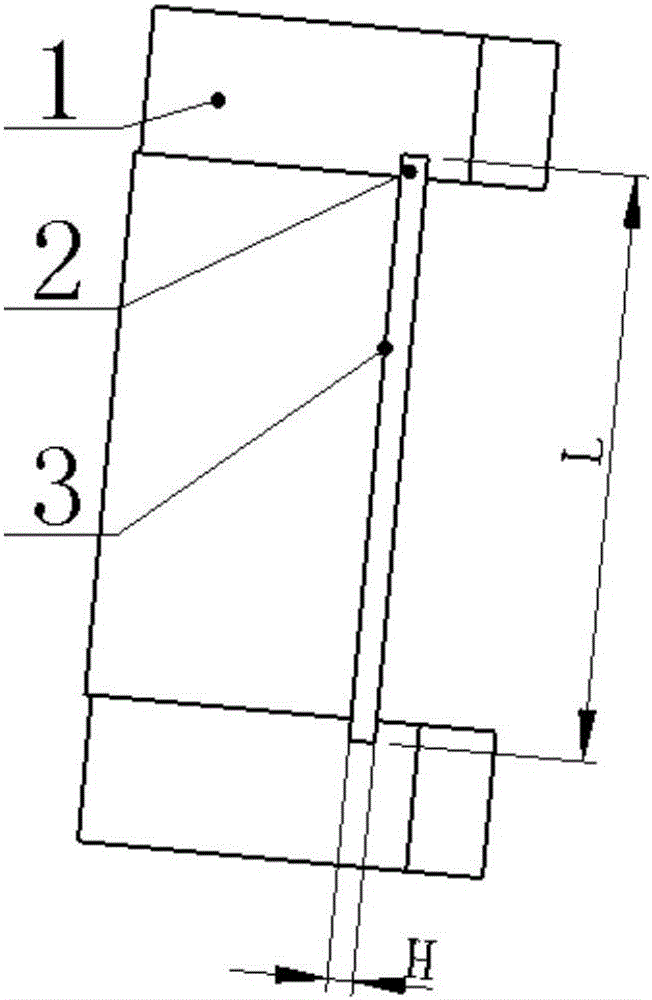

Connection tube of steel wire mesh framework composite tube and manufacturing method thereof

InactiveCN101672404AGood dimensional stabilityDisadvantages of Avoiding Unreasonable ShrinkagePipe connection arrangementsState of artElectricity

The invention relates to a connection tube of a steel wire mesh framework composite tube and a manufacturing method thereof. The connection tube of the steel wire mesh framework composite tube comprises a steel wire mesh framework composite tube main body (1) and electric welding fittings (2). The connection tube of the steel wire mesh framework composite tube is characterized in that each connection port of the steel wire mesh framework composite tube main body (1) and the electric melting tube (2) are fused into a whole by an injection molding technology. Because the electric melting tube and the steel wire mesh framework composite tube main body are formed integrally by a secondary injection molding process in advance, the size stability of the tube is better, and the defect of unreasonable contraction of the wall thickness, caused by the condition that the electric melting tube and a composite tube of the prior art are separated and can be installed only when being matched, is avoided; the invention can also regulate the formed tube secondarily to match with a size tolerance, the connection mode is safe and firm, and the interface strength is high.

Owner:GUANGDONG LIANSU TECH INDAL

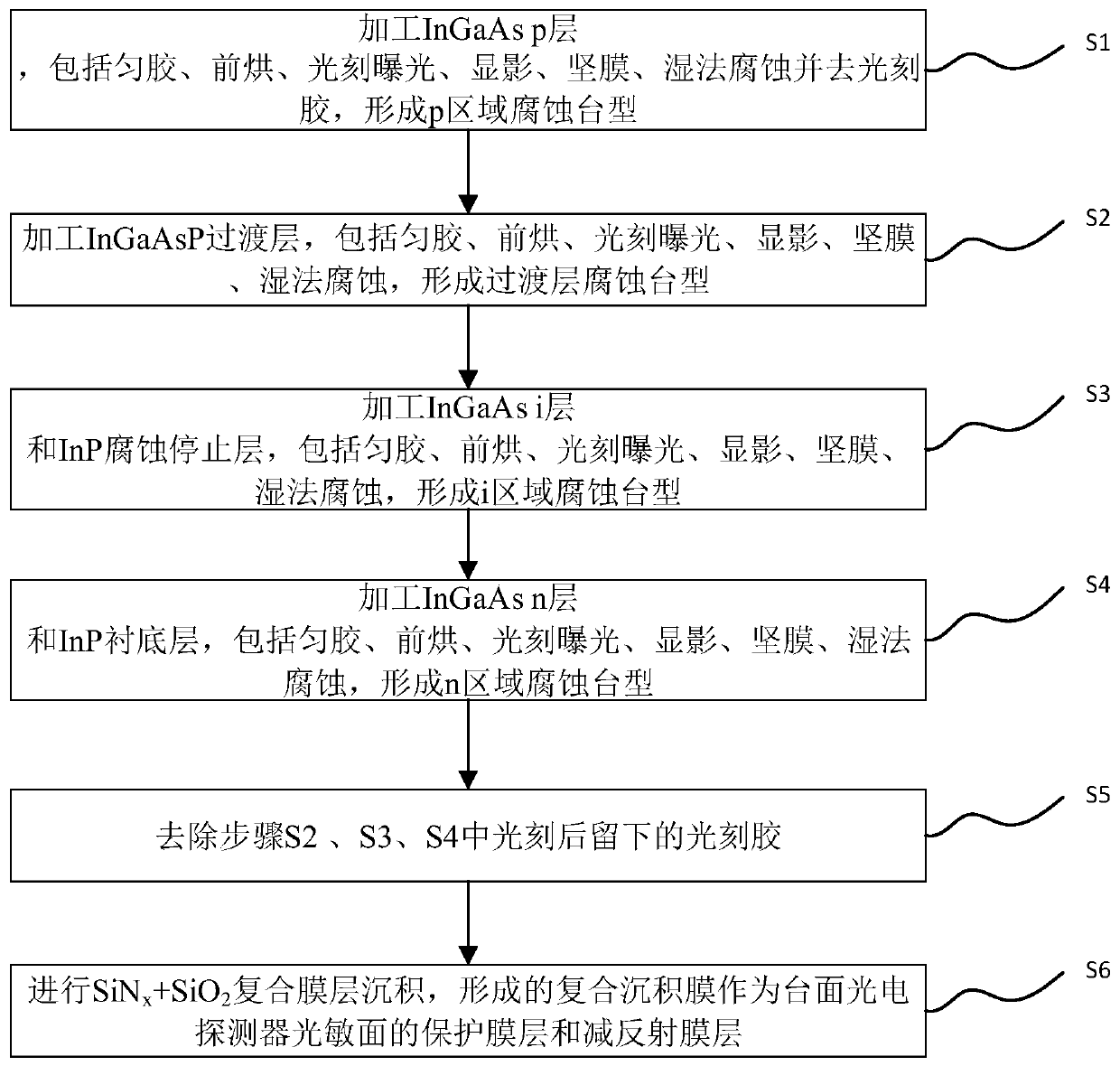

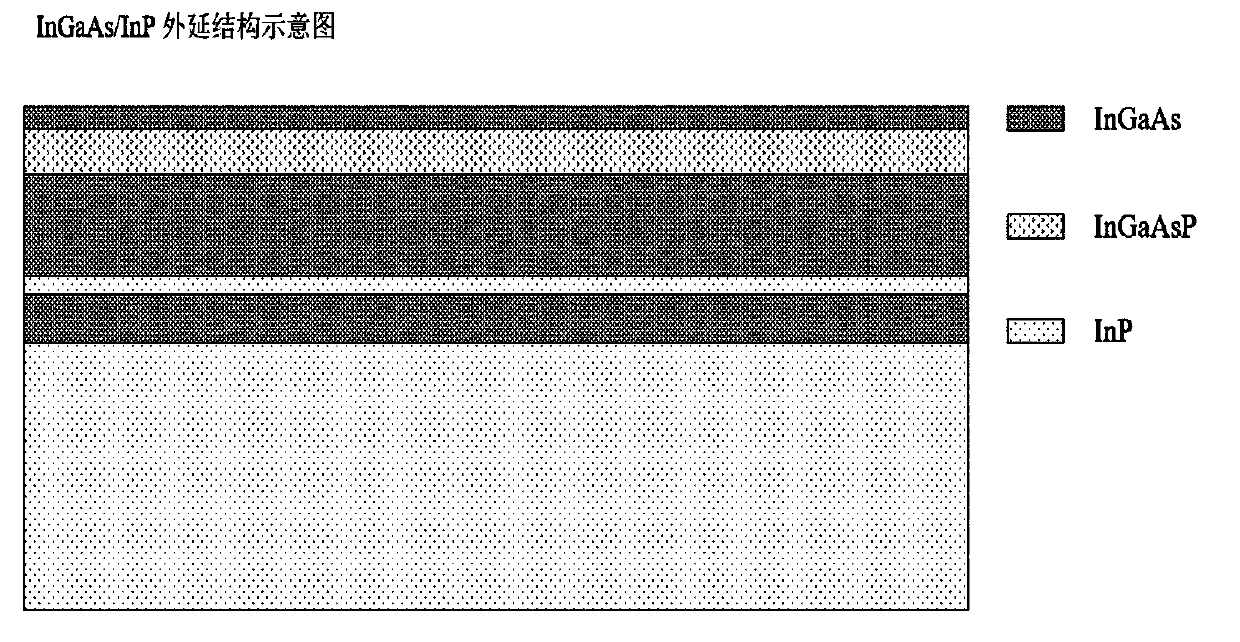

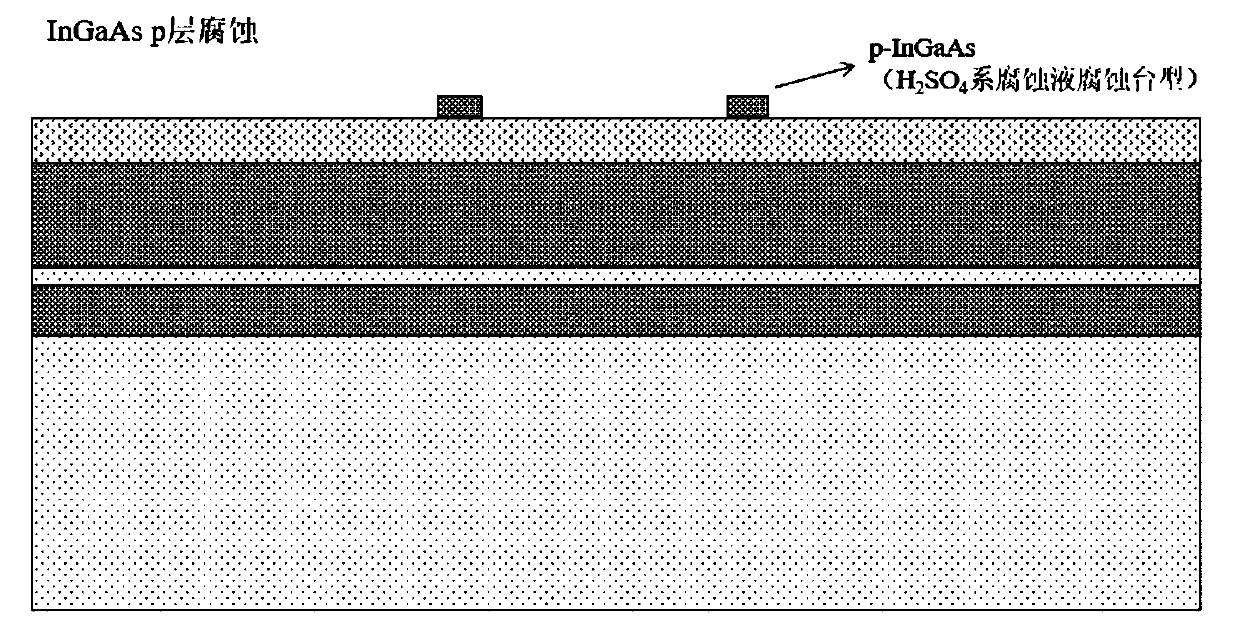

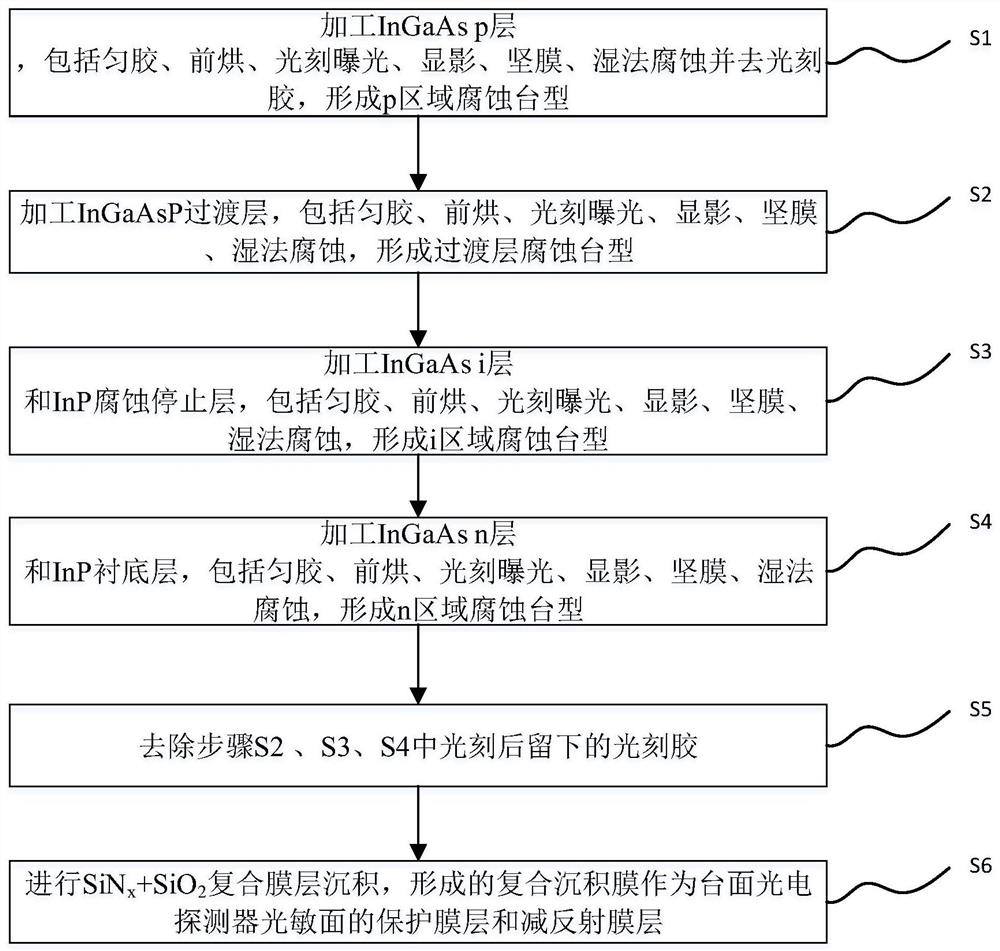

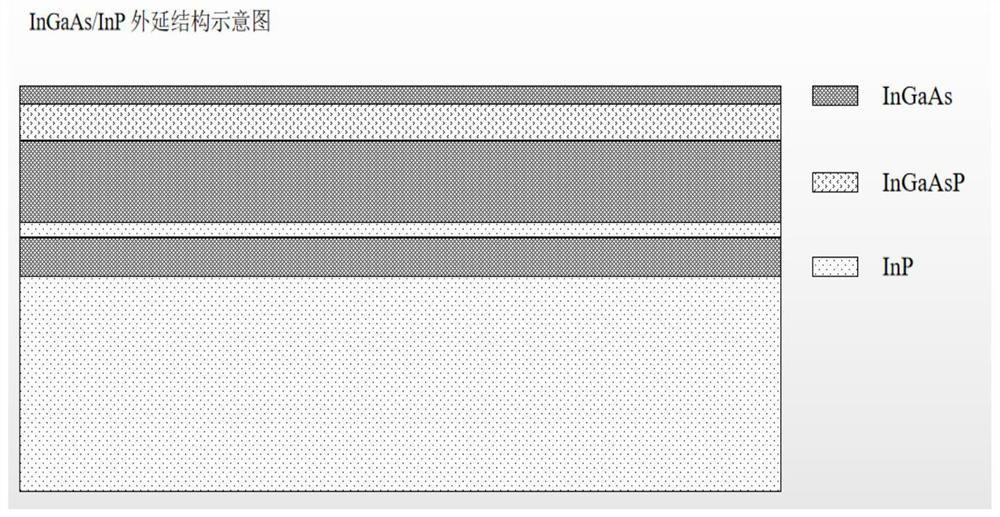

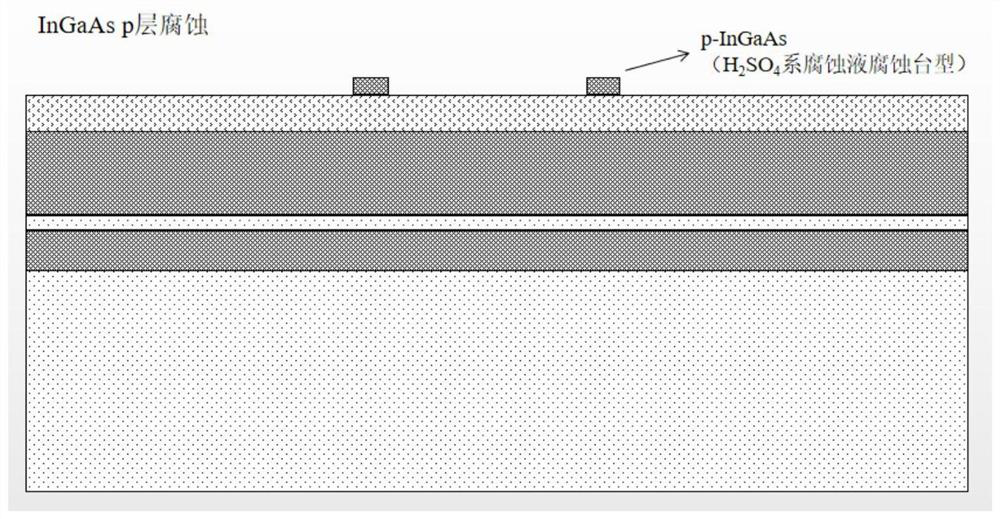

Manufacturing method of mesa type photoelectric detector

ActiveCN110707181AAvoid exposure to oxidationReduce the chance of formationFinal product manufactureSemiconductor devicesPhotovoltaic detectorsEngineering

The invention discloses a manufacturing method of a mesa type photoelectric detector. According to the manufacturing method, in the process of processing the InGaAsP transition layer, the InGaAs i layer, the InP corrosion stopping layer, the InGaAs n layer and the InP substrate layer, photoresist removing treatment is not carried out, and finally photoresist left after photoetching is removed at atime. According to the invention, the gluing layer is used for fully protecting the photosensitive surface structure of the photoelectric detector; the InGaAs / InP PIN mesa photoelectric detector withhigh performance is obtained by removing photoresist, cleaning the InGaAs / InP PIN mesa photoelectric detector, avoiding bringing new impurities and contact oxidation with oxygen in the steps of photoresist removal, cleaning and the like, reducing the formation probability of the surface state of the device, and reducing the dark current of the device.

Owner:武汉敏芯半导体股份有限公司

Stainless steel slagging and degassing refining agent

This invention relates to a rustless steel slag-forming and degassing agent, which is specifically a casting accessory material to clean up rustless steel molten steel surface and improve rustless steel quality, and belong to metal surface treatment technique area in foundry industry. This agent mainly comprises 70-80 wt% of dolomite, 10-15 wt% of aluminum dust and 6-15 wt% of fluor. The components are mixed completely in normal temperature and packed to completed product. This invention possesses the properties of increasing life of brasque to more than 200 times; improving slag-forming ability to decrease endermic points, decrease surface points and pocks of buffing surface and increase rate of finished products and improving thermal insulation and degasification by floating constantly on the surface of molten steel, in which molten steel is prevented to contact with air and oxygenized, suck in hydrogen and nitrogen and interfused with foreign substance, so as to ensure cleaner molten steel higher property.

Owner:张华静

Preparation method for wrapping surfaces of ceramic particles with metal

InactiveCN110625111AImprove wettabilityImprove bindingMolten spray coatingTransportation and packagingAcid washingBiological activation

The invention relates to a preparation method for wrapping the surfaces of ceramic particles with metal, and belongs to the field of metal-ceramic composite. The method comprises alkali treatment, acid treatment, wrapping treatment and mixing, wherein in the wrapping treatment, the mass ratio of ceramic powder to metal powder, NH4Cl and metal hydride is (80-95):(12-25):(8-20):(15-25); and during mixing, the mass ratio of the ceramic powder to the metal powder is (40-70):(30-60). According to the preparation method, firstly alkali washing and acid washing are carried out on the ceramic particles, that is, activation treatment is carried out, then the ceramic particles after the alkali washing and acid washing are uniformly mixed with the metal powder, NH4Cl and the metal hydride for vacuumreaction treatment, and the surfaces of the ceramic particles are wrapped with the layer of metal; and therefore, oxidation is avoided, wetting and compatibility with the metal are improved, and the coating retains the characteristics of high hardness, friction and wear resistance and chemical corrosion resistance of the ceramic. The preparation method has the advantages of simple process, low equipment requirement and convenient batch production.

Owner:山东东大新材料研究院有限公司 +1

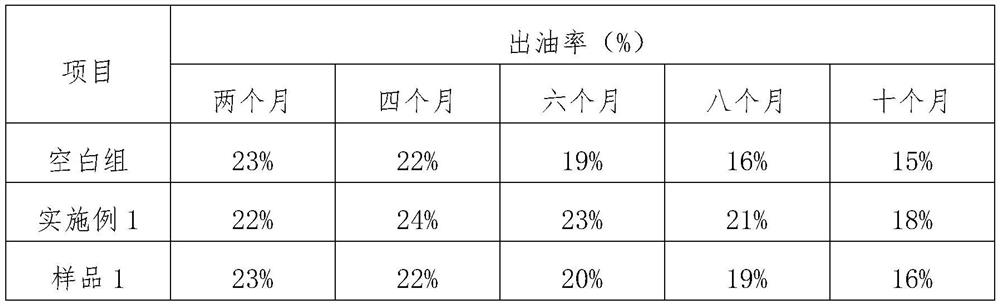

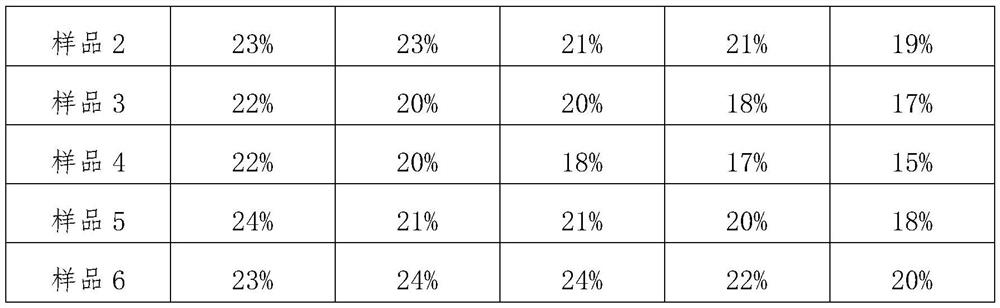

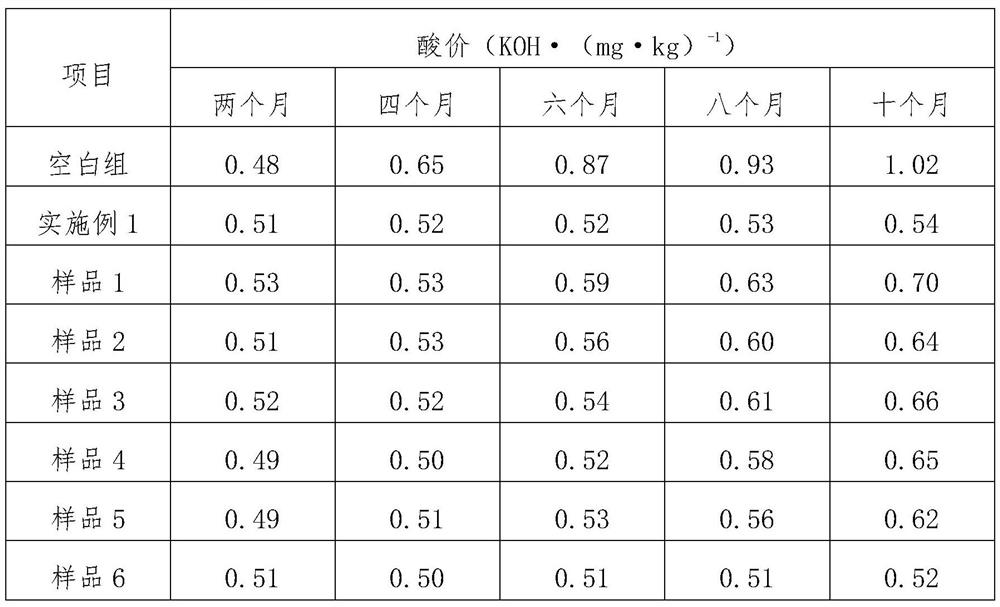

Method for slowing down oil storage consumption of camellia oleifera fruit

PendingCN111972491AReduce fuel consumptionInhibition of cellular respirationFood ingredient as antioxidantSeed preservation by coatingChemistryFilm coating

The invention belongs to the technical field of storage and preservation, and particularly relates to a method for slowing down oil storage consumption of camellia oleifera fruit. An inhibitor and a light absorption film are combined to jointly slow down the oil consumption of the camellia oleifera fruit, and the inhibitor inhibits the cell respiration of the camellia oleifera fruit and slows downthe oxidation rate of saccharides; film coating treatment is performed on the surface of camellia oleifera fruit shell, so that the camellia oleifera fruit can be isolated from most air while ultraviolet rays are absorbed, the oxidation speed is reduced, the moisture in the camellia oleifera fruit shell is retained, and the quality of camellia oleifera seeds is ensured.

Owner:贵州石阡佛顶山野生油茶油业有限公司

Carrot powder processing method

The invention relates to a carrot powder processing method and belongs to the technical field of health food. The method includes the steps of 1), selection of raw materials, namely selecting leftovers of disease and pest free carrot processing products and removing decayed parts; 2), sterilization and condensation; 3), pulping, namely crushing the raw materials subjected to condensation to produce a pulping object; 4), drying, namely putting the pulping object into the partition of a drying box for freezing at the freezing temperature of minus 20DEG C for 1 hour, and subjected the frozen raw materials to sublimation drying; 5), crushing, namely placing dried particle materials into a pulverizer to be pulverized into powder and controlling the particle size to be under 20 meshes; 6), packaging, namely packaging and sealing with composite plastic thin films according to grades. In the method, steam sterilization and the condensate liquid sealing technology are combined, an original production technology is simplified, and the method has the advantages of simpleness in technology and hygiene and security.

Owner:兴化市绿禾食品有限公司

Process for inlaying gold and silver into ceramic

The invention discloses a process for inlaying gold and silver into ceramic. The process comprises the following steps of: sketching a script on a ceramic blank, coating the gold and the silver according to the requirement of the script, drying, coating an anti-oxidation glaze protective layer, and sintering. The gold and the silver are simultaneously inlaid in the ceramic blank to form a picture, so that the gold and silver inlaid part of the ceramic has multi-thickness effect, and the ornament is enhanced; the gold and the silver are staggered and fused together with the anti-oxidation glaze protective layer by high-temperature sintering, so that the formed picture has depth change and excellent light transmission property; gold powder and silver powder are not mixed together in making through an isolating agent; and the gold and the silver are prevented from being oxidized by air due to contact through the anti-oxidation glaze protective layer, and the gold and the silver are not easily directly contacted so as to avoid abrasion.

Owner:吴晓春

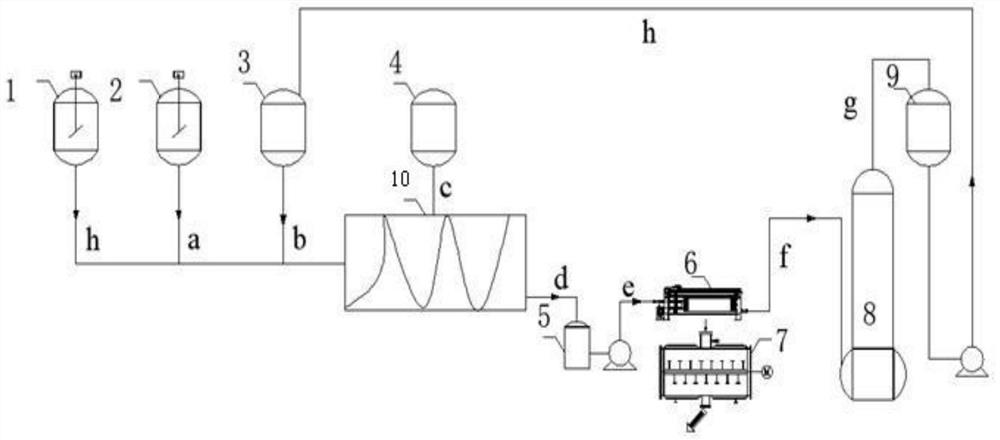

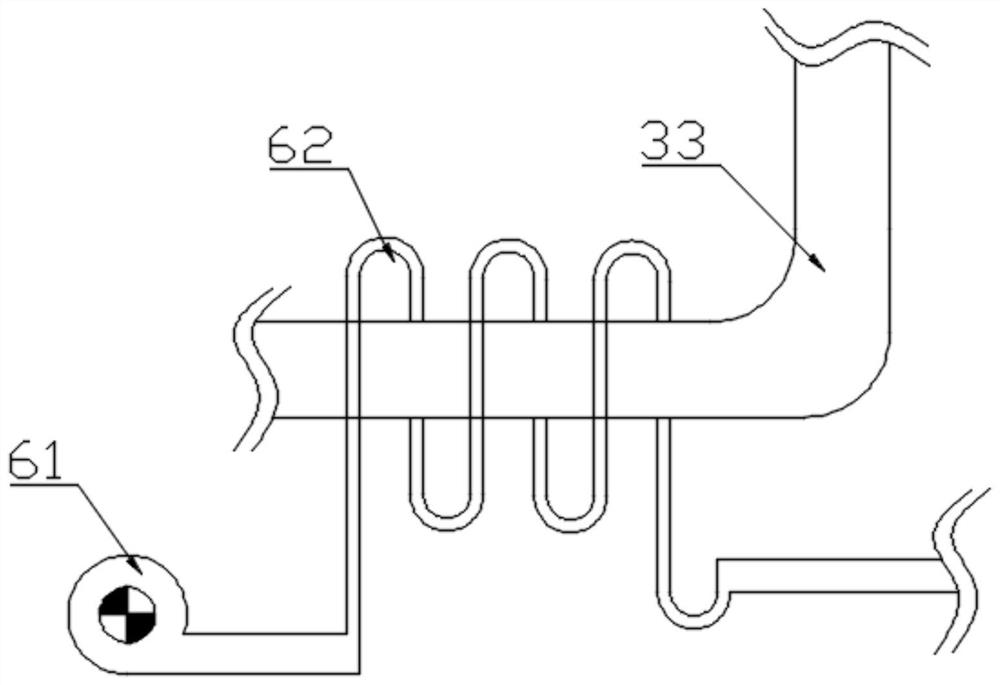

Process and device for continuously producing bentazone intermediate o-aminobenzoic acid

ActiveCN112159332ASolving the Problem of Waste Organic SolventsLow costOrganic compound preparationChemical/physical/physico-chemical microreactorsBenzoic acidPropylamine

The invention discloses a process and a device for continuously producing bentazone intermediate o-aminobenzoic acid isopropyl amine by taking phthalimide as a raw material. The process comprises thefollowing steps: (1) adding phthalimide solid and pure water into a reaction kettle, stirring at a low speed, adding a 32% sodium hydroxide solution, and stirring at normal temperature for 30 minutes;(2) respectively feeding the phthalimide sodium salt solution and the sodium hypochlorite solution into a micro-channel reactor according to a certain flow rate, carrying out a Huffman rearrangementreaction at a low temperature, and feeding the mixture into a temporary storage tank; (4) mixing the reaction solution in the temporary storage tank 1 with hydrochloric acid (or sulfuric acid and thelike) through a static mixer, feeding the mixture into a reaction kettle, heating the mixture to room temperature, adding an isopropylamine aqueous solution at a certain flow rate, and continuously stirring for 2-3 hours; (4) enabling the solution to pass through a plate-and-frame filter press, returning the filtrate to the first step for repeated application, and drying the filter cake to obtainisatoic anhydride with the purity of 99% or above.

Owner:QINGDAO UNIV OF SCI & TECH

Copper bar connector with strong sealing performance and convenient maintenance

PendingCN114284815AImprove ease of useGuaranteed electrical conductivitySecuring/insulating coupling contact membersCoupling contact membersStructural engineeringMechanical engineering

The invention relates to the technical field of copper bar connection, in particular to a high-sealing-performance convenient-to-overhaul copper bar connector which comprises two copper bars, the two copper bars are jointly and movably sleeved with a connecting frame, and the two copper bars are fixedly sleeved with fixing sleeves used in cooperation with the connecting frame. The copper bar connecting device is reasonable in design and ingenious in structure, through mutual cooperation of the structures, the copper bar connecting device can adapt to connection of various copper bars of different models, operation is easy and fast, the good sealing performance is achieved, oxide can be effectively prevented from being generated at the connecting position of the copper bars, and the service life of the copper bars is prolonged. And when a connection fault occurs between the two copper bars due to high temperature, power can be cut off in time, and the corresponding prompt lamp is turned on, so that each connection part does not need to be detected, the maintenance efficiency can be effectively improved, and the device has good market competitiveness and is worthy of recommendation.

Owner:NANTONG ZHUOER ELECTROMECHANICAL CO LTD

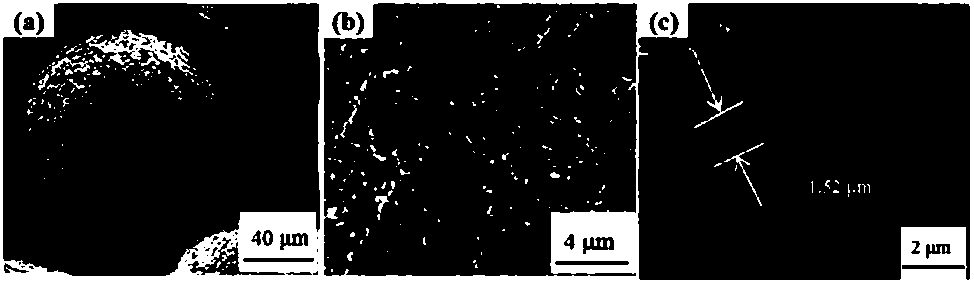

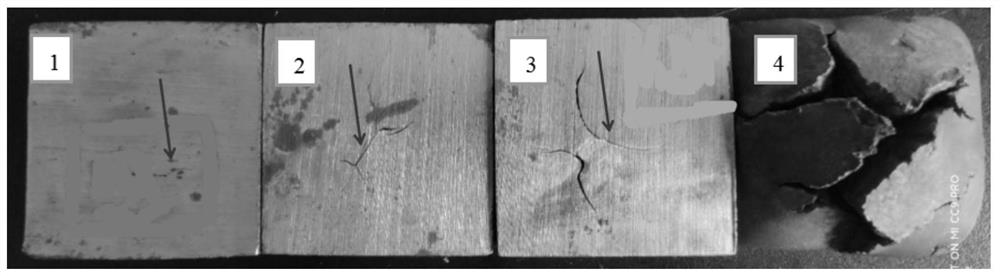

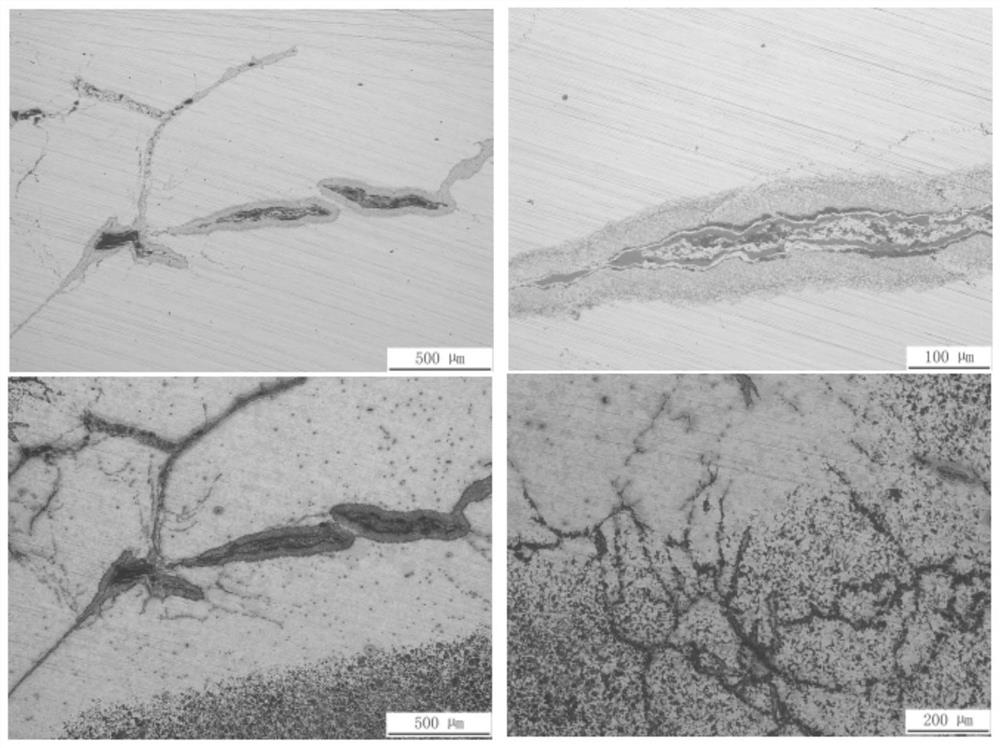

Analysis method of material failure crack source

ActiveCN112881642AAccurate judgmentAvoid severe wear and tearMaterial analysisStructural engineeringMachining process

The invention provides an analysis method of a material failure crack source, and belongs to the field of material detection. The analysis method of the material failure crack source comprises the steps of acquiring a failure sample and at least one intermediate sample from parts in the same batch or the same part, wherein the failure sample is taken from the fractured part of the part, and the intermediate sample is taken from the unfractured part of the part; selecting an intermediate sample with an intermediate crack as a crack sample, wherein the the position of the intermediate crack corresponds to the fracture position of the failure sample; and determining the position of the failure crack source of the part according to the position of the intermediate crack in the crack sample. According to the analysis method, the interference of the use environment and the machining process of the part on crack source searching can be effectively reduced.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

Novel dry-method degumming method for abandoned oil

InactiveCN102071103BSave waterSimple operating conditionsFatty-oils/fats refiningPhosphoric acidColloid

The invention mainly aims to solve the problems caused by degumming in the process of processing abandoned oil serving as raw materials. By dry-method degumming, the series of problems can be solved effectively. The method comprises the following steps of: adding a certain amount of acid (strong phosphoric acid: citric acid is 2:1) into a material system, and reacting at the temperature of 100 and 115 DEG C for 55 to 85 minutes, so that phospholipid in the abandoned oil serving as the raw materials is flocculated to form large granular flocculate; stirring a mixture, which serves as an adsorbent, of quantitative silica gel and carclazyte continuously for 50 and 80 minutes under the vacuum degree of between 0.080 and 0.098 MPa, wherein the addition of the adsorbent is between 0.5 and 2.0 percent; and cooling the integral material system to a certain extent, filtering the hot material system, and filtering out colloid and part of pigments by adsorption. The process has a simple operational condition, does not generate oilfoot, is less in pollution, can improve the yield of products by over 2 percent, achieves the discoloring effect while degumming, and improves the quality of oils obviously.

Owner:湖南欣林生物油脂工程技术有限公司

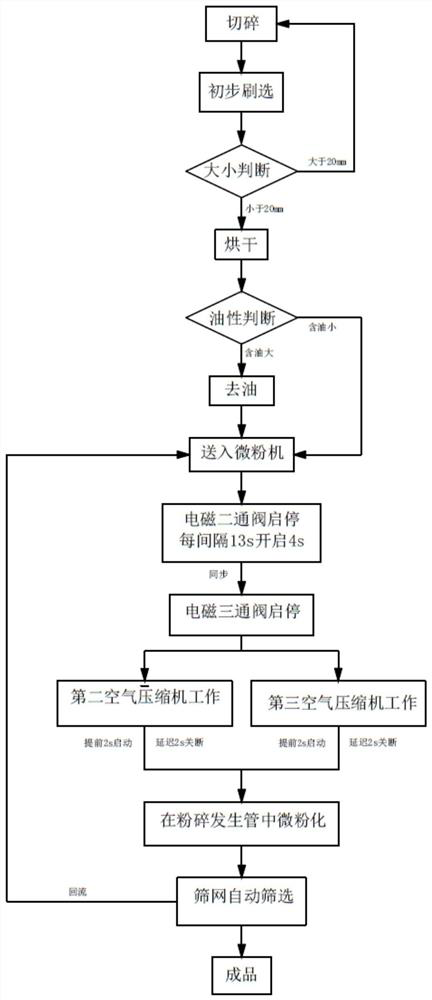

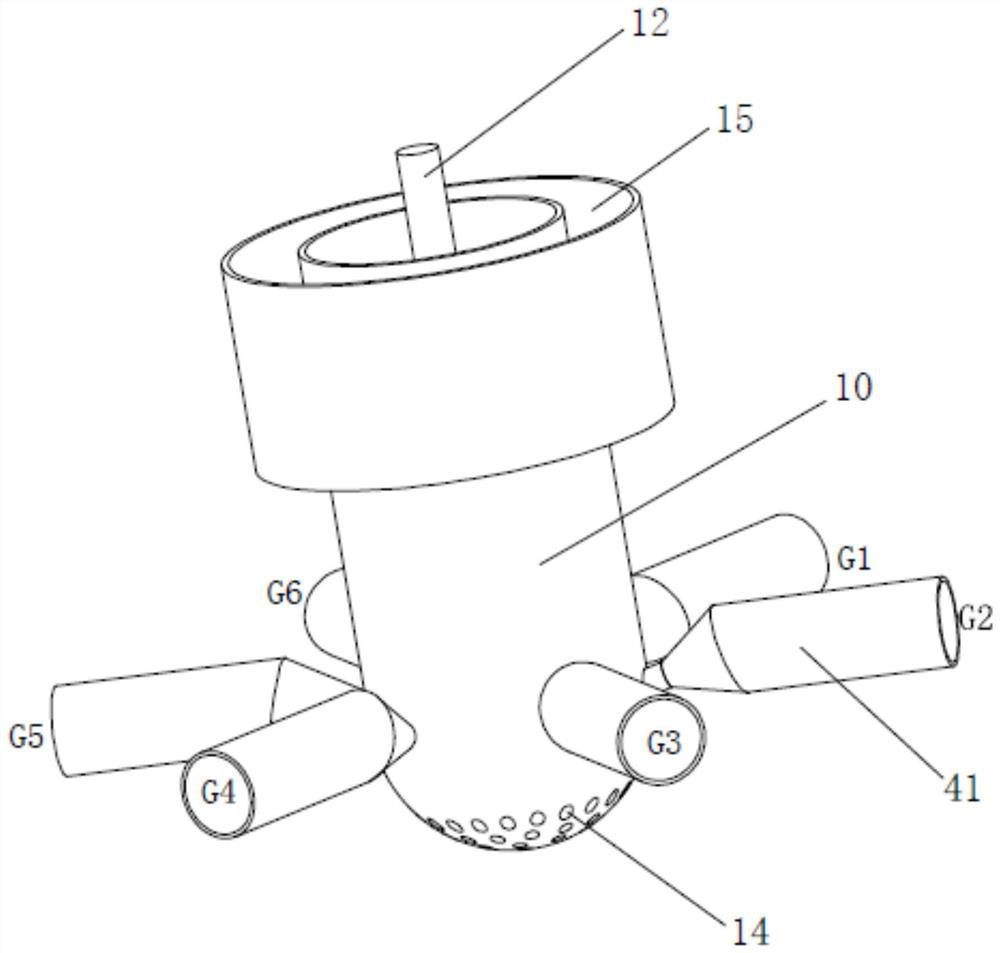

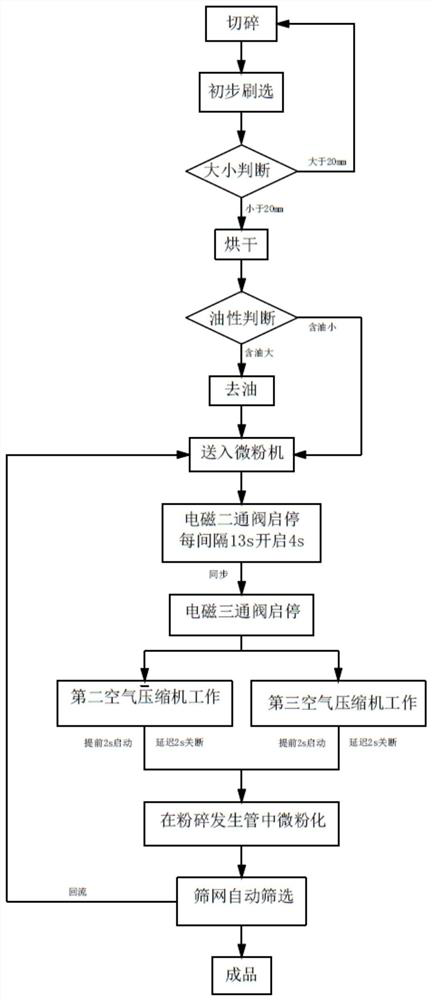

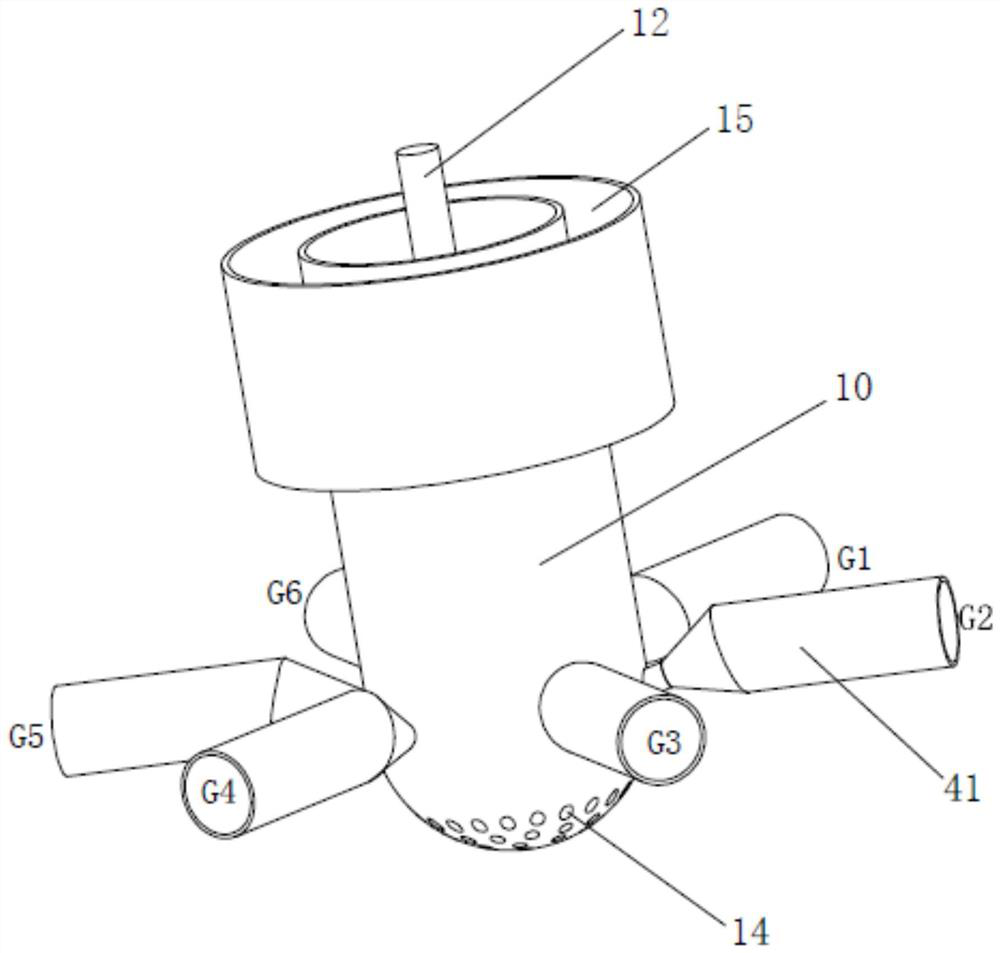

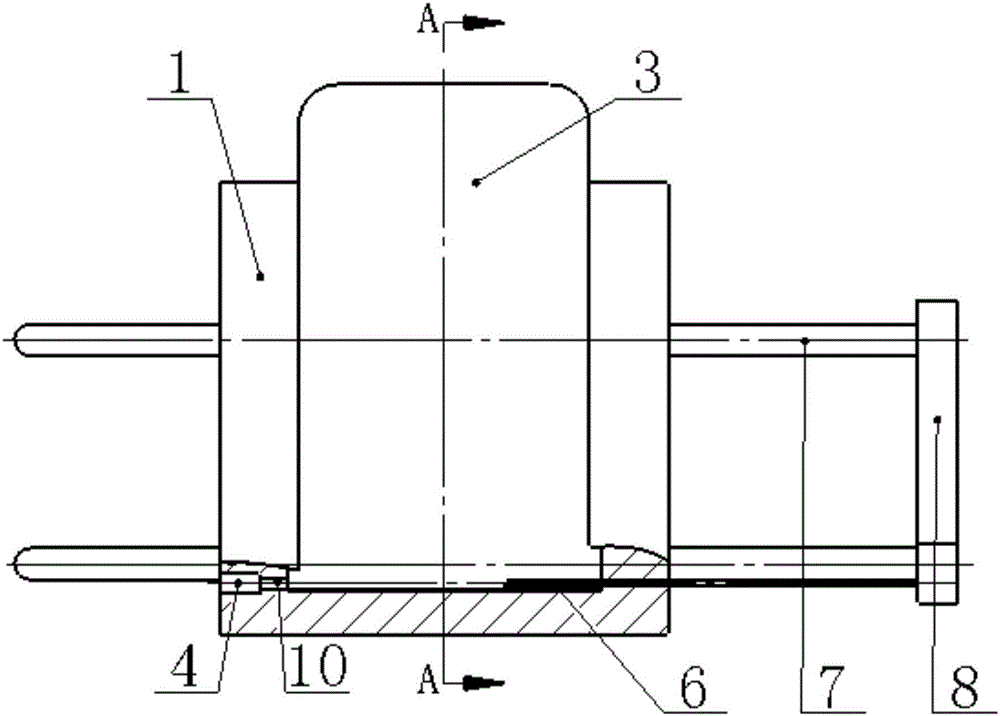

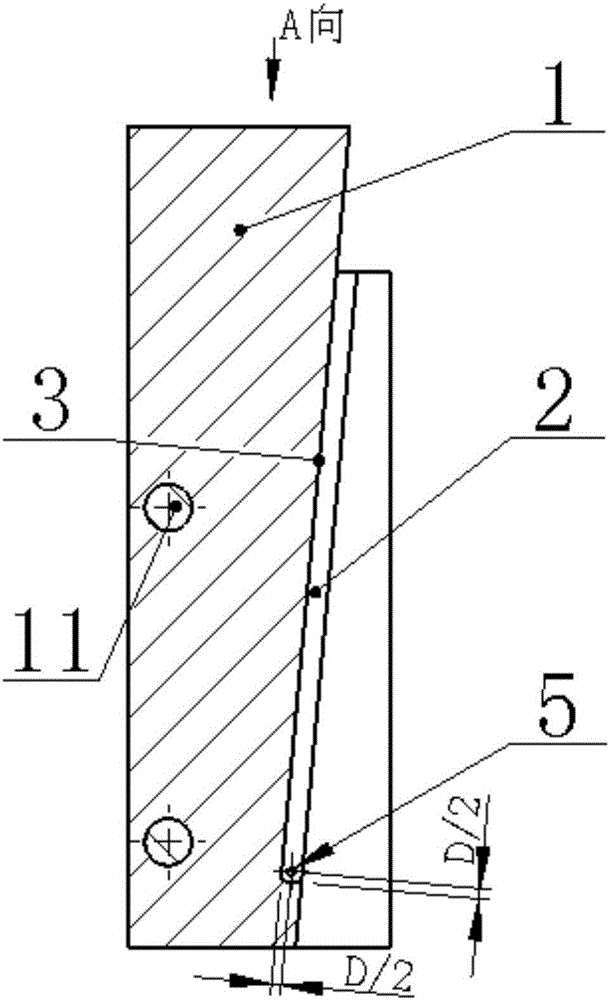

Fine grinding method for direct oral medicinal slice raw materials

The invention discloses a fine grinding method for direct oral medicinal slice raw materials. The fine grinding method is fewer in processes, simple to operate, and does not need to excessively dry and remove oil in advance; high-speed gas flow is adopted to drive medicine particles to collide with a metal inner wall and a turning fork, so that collision force is greater and the crushing effect isbetter; a spray head alternatively sprays high-speed gas flow with the medicine particles, so that the motion of the medicine particles is more disordered, and collision frequency is increased; low-temperature nitrogen gas conveying is adopted throughout the process, so that the medicines are prevented from oxidizing and generating heat breaking; the raw material particles are embrittled, so thatcrushing degree is improved; and after the turning fork is collided, sound waves of various frequencies are not generated, so that Brownian motion degree of medicinal slice powder is increased, a sticking phenomenon is weakened, and the crushing effect is further improved.

Owner:桂林中南(亳州)药业科技有限公司

Process for continuously producing anthranilic acid

PendingCN114014769AIncrease conversion rateReduce consumptionOrganic compound preparationChemical/physical/physico-chemical microreactorsIsatoic anhydrideBenzioc acid

The invention discloses a process and a device for continuously producing anthranilic acid by taking phthalimide as a raw material. A process for continuously producing anthranilic acid by taking phthalimide as a raw material comprises the following steps of: (1) adding a phthalimide solid and pure water into a reaction kettle, stirring at a low speed, adding a 32% sodium hydroxide solution, and stirring at normal temperature for 30 minutes; (2) enabling a phthalimide sodium salt solution, a 32% hydrogen peroxide solution and a hydrochloric acid solution to respectively enter a micro-channel reactor according to a certain flow rate, be subjected to a Hofmann rearrangement degradation reaction at low temperature, and enter a temporary storage tank; and (3) pressurizing the slurry in the temporary storage tank through a slurry pump to enter a plate-and-frame filter press, treating the filtrate through a filtrate removal tower, then repeatedly applying the filtrate, and drying a filter cake to obtain isatoic anhydride with the purity of 99% or above.

Owner:QINGDAO UNIV OF SCI & TECH

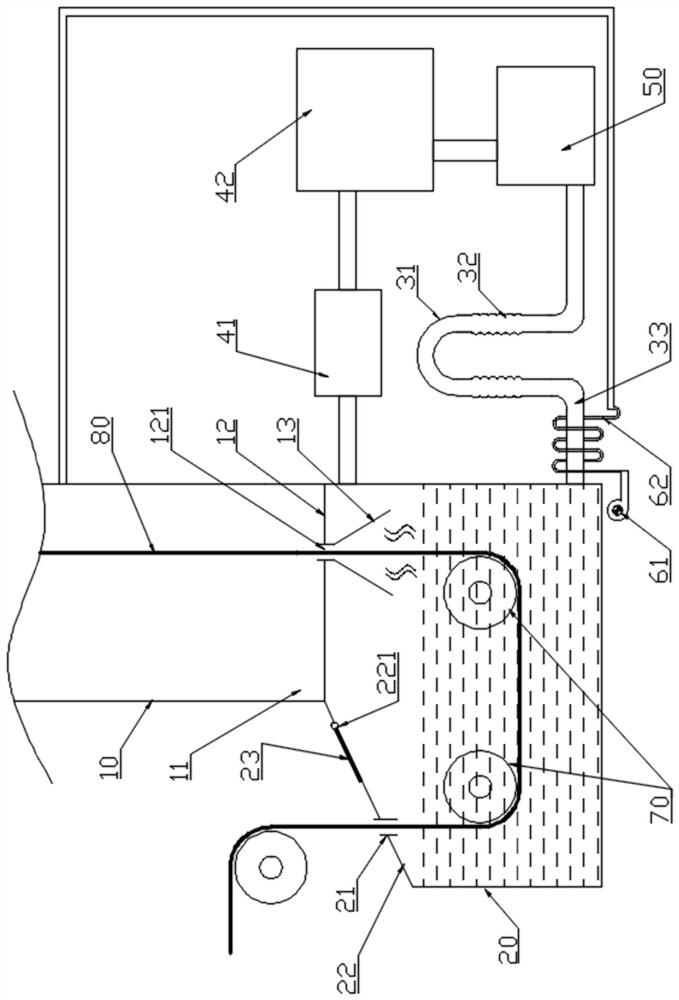

Vertical annealing device for enameled wire

ActiveCN112746166ARaise the water levelHeight adjustableFurnace typesHeat treatment furnacesElectrical conductorMetallurgy

Owner:广东松田科技股份有限公司

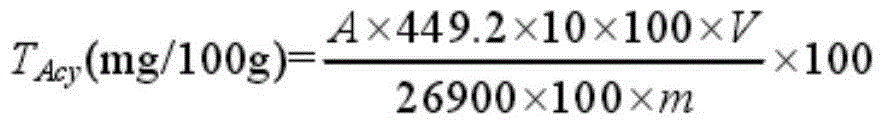

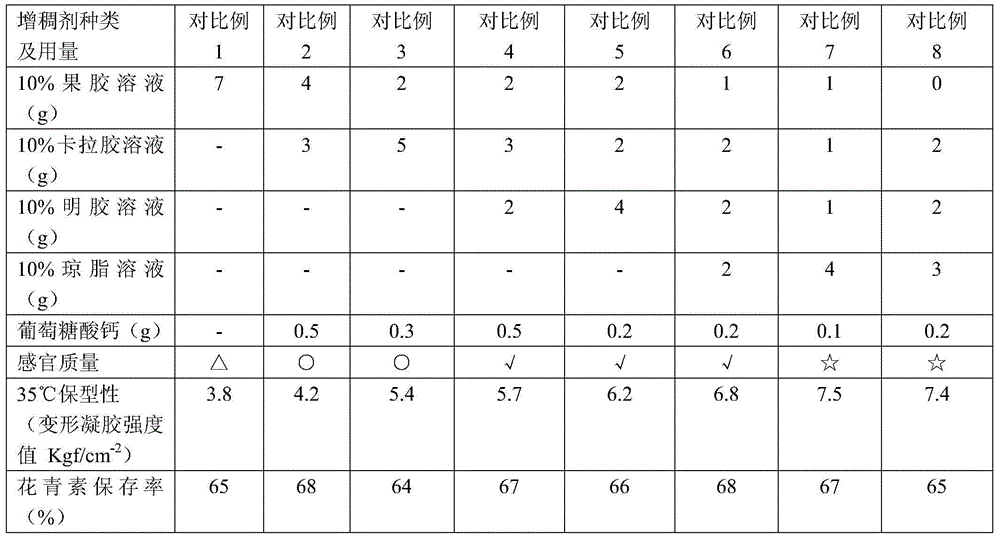

A kind of method that utilizes blueberry pomace to produce blueberry fruit cake

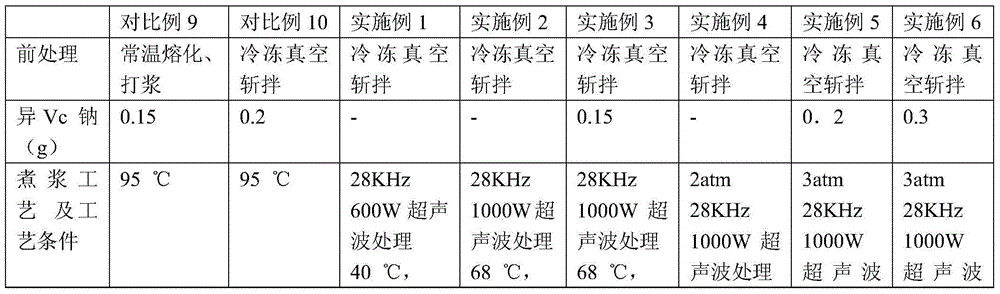

InactiveCN103892154BAvoid churnAvoid exposure to oxidationFood freezingFood thermal treatmentFreeze thawingFruit cake

The invention provides a method for developing fruit cakes by utilizing blueberry juice residual residues as a raw material. The method comprises the following steps: directly performing vacuum freezing chopping treatment on frozen blueberry residues without melting and pulping, accelerating the dissolution of active ingredients in a manner of combining ultrasonic emulsification treatment with proper heat treatment, wherein the manner replaces a traditional boiling process, performing high-pressure pasteurization, and finally cooling and molding. Part of macromolecular hydrophilic colloid is added before sterilization, and the gel strength and the shape maintenance are improved. The method is simple to operate, low in heat treatment strength and short in time, and repeated freeze thawing and high-strength heat treatment of a product are avoided. Therefore, the method has the advantages that the microbial pollution probability is low, the retention rate of the effective active ingredients is high, the sensory quality is excellent, the shape maintenance at the temperature of 37-42 DEG C is good and the like.

Owner:ZHEJIANG UNIV OF TECH +1

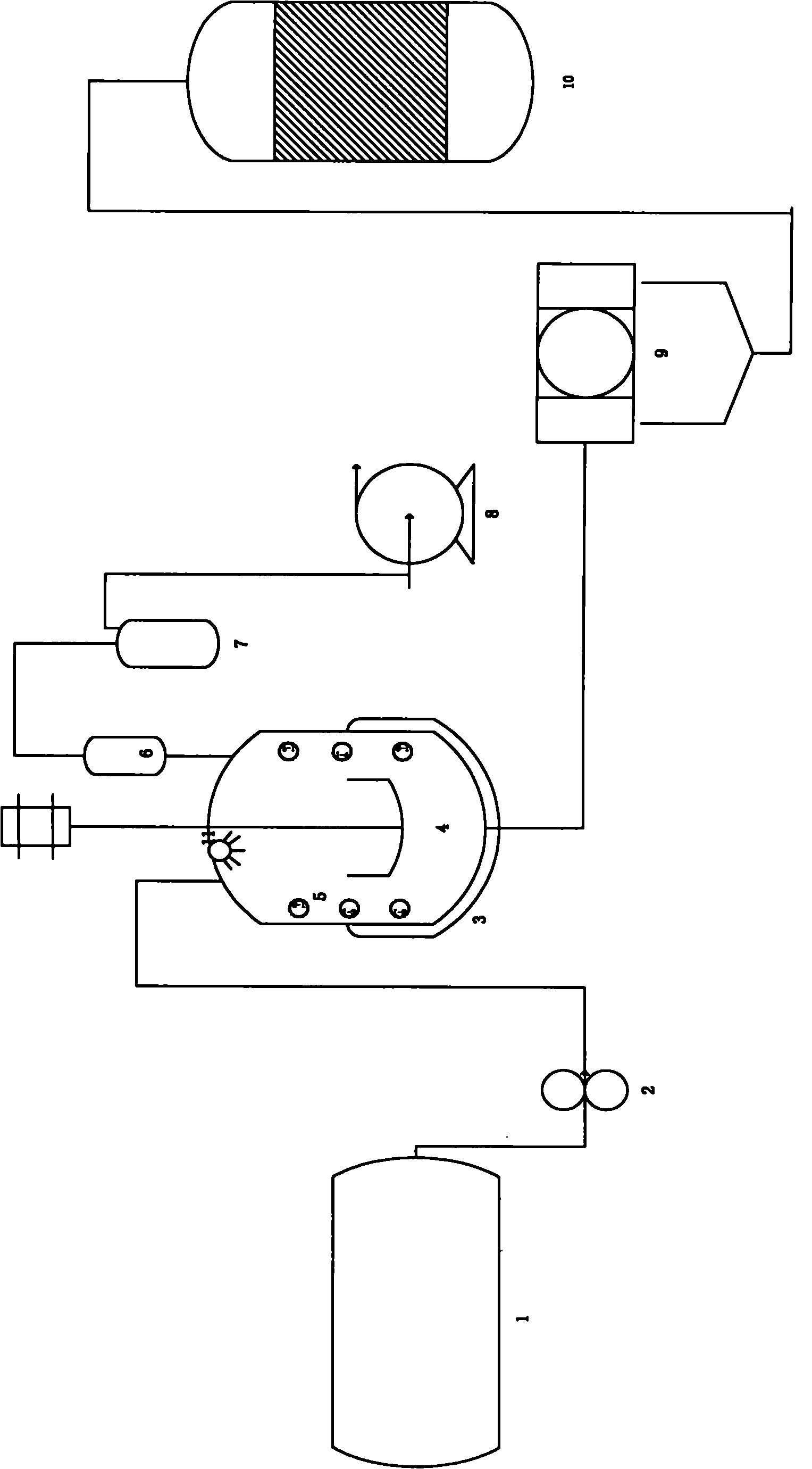

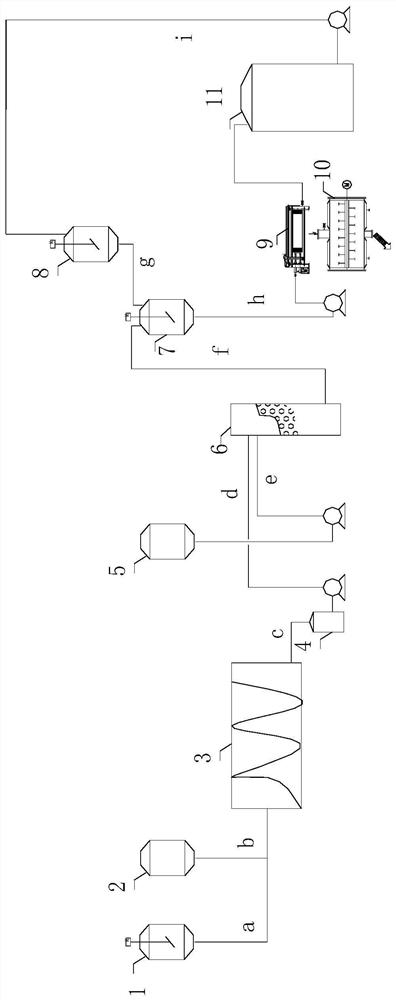

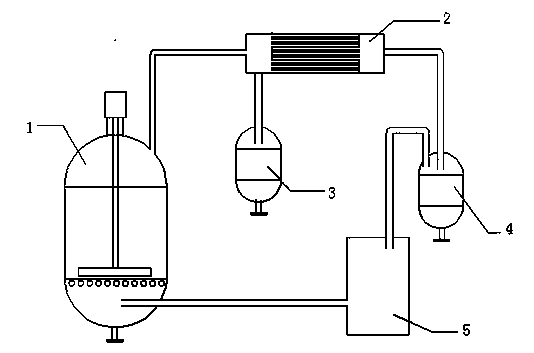

Soaking apparatus

InactiveCN103877735ASimple structureEasy to operateVapor condensationEvaporationBuffer tankProcess engineering

A disclosed soaking apparatus comprises an evaporator connected with the left end of a condenser via a pipe, the lower part of the condenser is communicated with a receiving tank via a pipe, the right end of the condenser is connected with a buffer tank via a pipe, the buffer tank is connected with a vacuum pump via a pipe, and the vacuum pump is connected with the evaporator via a pipe. The soaking apparatus is simple in structure and convenient to operate. By adding the vacuum pump into the soaking apparatus, solvent recovery automation is realized, the work efficiency is improved, also a solvent is prevented from oxidation caused by being exposed and contacting air when the solvent is recovered, and the quality of the solvent is improved.

Owner:FULLER BIOTECH

A kind of preparation method of lithium cobalt phosphate cathode material for lithium battery

ActiveCN109301199BAvoid exposure to oxidationImprove electrochemical cycle performanceCell electrodesSecondary cellsO-Phosphoric AcidLithium hydroxide

Owner:GUANGZHOU TIGER HEAD BATTERY GROUP

Fabrication method of mesa photodetector

ActiveCN110707181BAvoid exposure to oxidationReduce the chance of formationFinal product manufactureSemiconductor devicesPhotovoltaic detectorsPhotoresist

The invention discloses a manufacturing method of a mesa type photoelectric detector. According to the manufacturing method, in the process of processing the InGaAsP transition layer, the InGaAs i layer, the InP corrosion stopping layer, the InGaAs n layer and the InP substrate layer, photoresist removing treatment is not carried out, and finally photoresist left after photoetching is removed at atime. According to the invention, the gluing layer is used for fully protecting the photosensitive surface structure of the photoelectric detector; the InGaAs / InP PIN mesa photoelectric detector withhigh performance is obtained by removing photoresist, cleaning the InGaAs / InP PIN mesa photoelectric detector, avoiding bringing new impurities and contact oxidation with oxygen in the steps of photoresist removal, cleaning and the like, reducing the formation probability of the surface state of the device, and reducing the dark current of the device.

Owner:武汉敏芯半导体股份有限公司

A method for smelting silicon wafer cutting waste under slight negative pressure

The invention relates to a method for smelting silicon wafer cutting waste under slight negative pressure, and belongs to the technical field of pyromelting silicon wafer cutting waste regeneration and recovery of silicon. The present invention aims at the problem that silicon powder is easily oxidized in the smelting process and the impurity removal efficiency is low in the smelting process due to the presence of moisture in the process of pyromelting and recycling silicon from silicon wafer cutting waste, and the micro-negative pressure device is moved directly above the melting furnace mouth, Turn on the vacuum device of the micro-negative pressure device to melt the silicon wafer cutting waste in a micro-negative pressure, so as to avoid the oxidation loss of ultra-fine silicon powder during the melting process and remove the volatile impurities in the silicon, so as to realize the simultaneous refining of the silicon melt. The invention creates a slightly negative pressure environment above the silicon melt, which can avoid the escape of smoke during the silicon smelting process and reduce environmental impact. The method of the invention has the advantages of simple equipment requirements, easy operation, environmental friendliness and suitability for large-scale industrial production.

Owner:KUNMING UNIV OF SCI & TECH

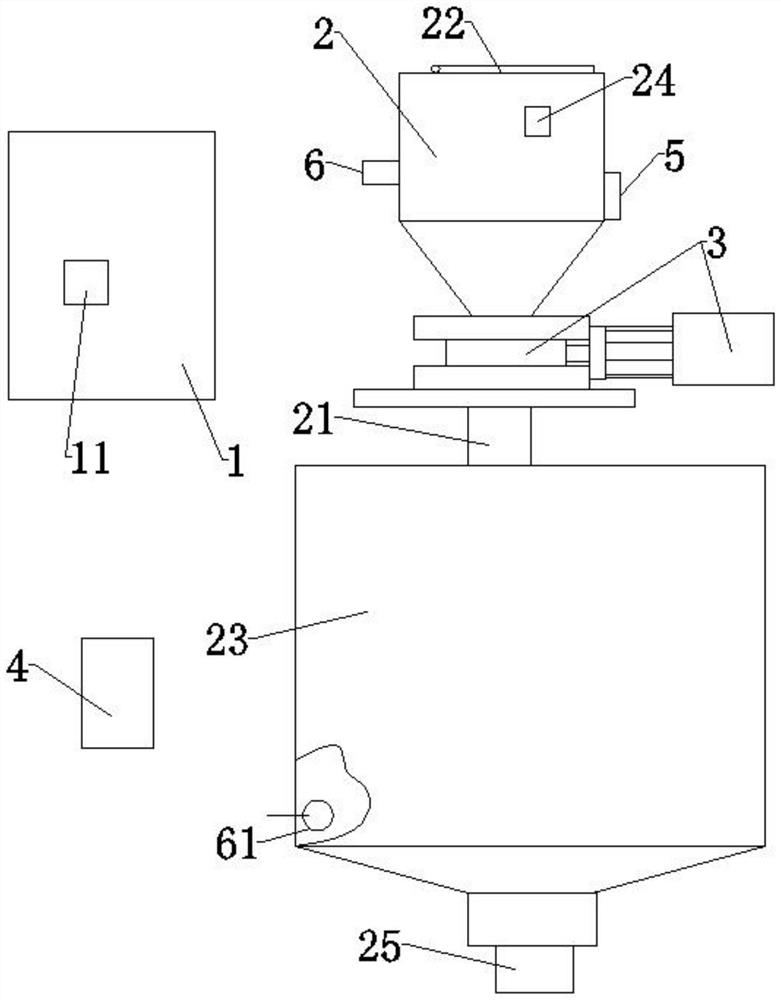

Feeding control system and control method for chinlon chip raw materials

PendingCN113816156AAvoid the situation where the feeding type does not matchAvoid cross-contamination situationsLarge containersMixer accessoriesControl systemControl engineering

The invention discloses a feeding control system and a control method for chinlon chip raw materials in the technical field of chinlon chip stock bins. The system comprises a feeding box, the feeding box is a feeding device for the chinlon chip raw materials, a bin cover for feeding is arranged at the top of the feeding box, a feeding identification code is arranged on the feeding box, a discharging port for the raw materials to enter a storage process at the bottom of the feeding box, and the bottom of the discharging port is connected with the stock bin with the fixed capacity. According to the feeding control system and the control method for the chinlon chip raw materials, manual recording is not needed, the feeding amount and material data of each time can be accurately recorded, whether chinlon slice raw materials in a raw material bag can be continuously fed into the stock bin or not can be judged, and according to the condition of the raw materials in the stock bin, a controller controls whether an automatic valve is opened or not, whether feeding can be carried out or not and whether the raw material type is matched with that in the stock bin or not can be prompted through a mobile terminal, use is very convenient and more intelligent, and the situation that the feeding type is wrong and the total feeding amount is wrong can be avoided through the system.

Owner:福建恒捷实业有限公司

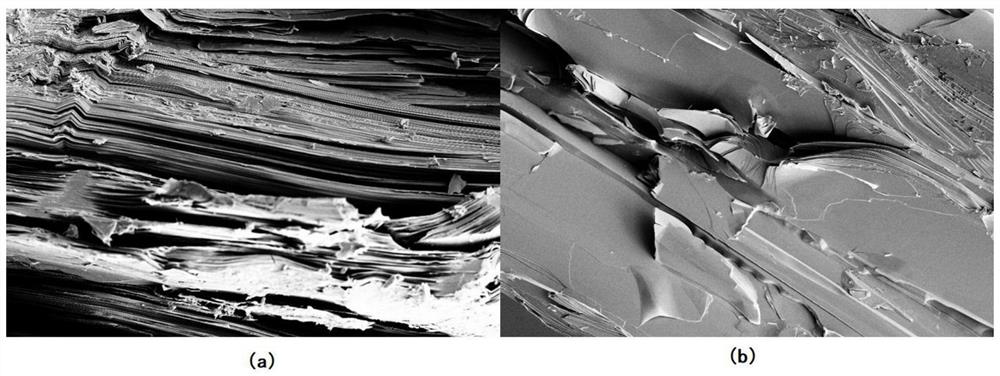

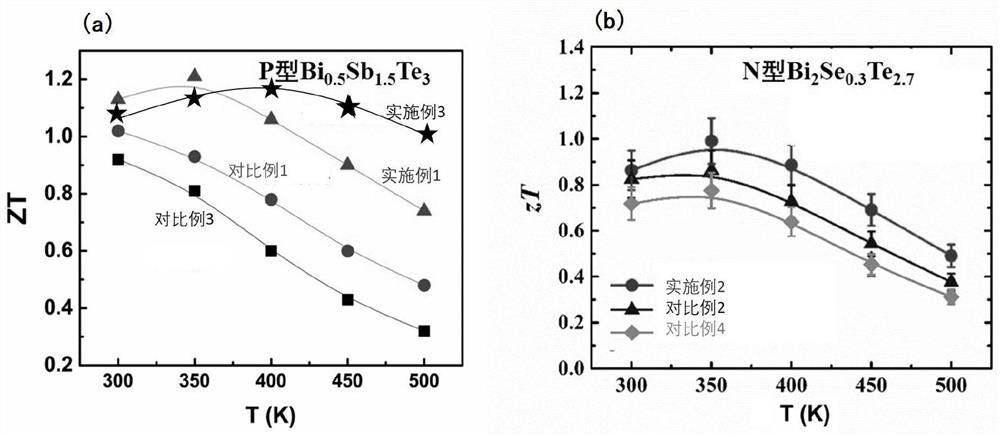

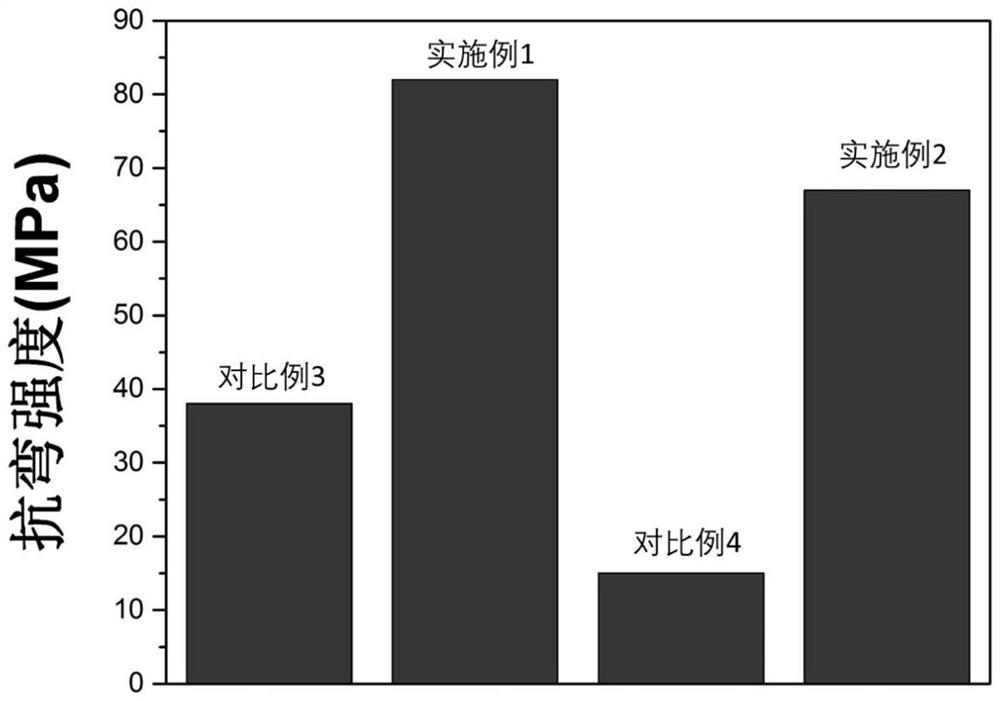

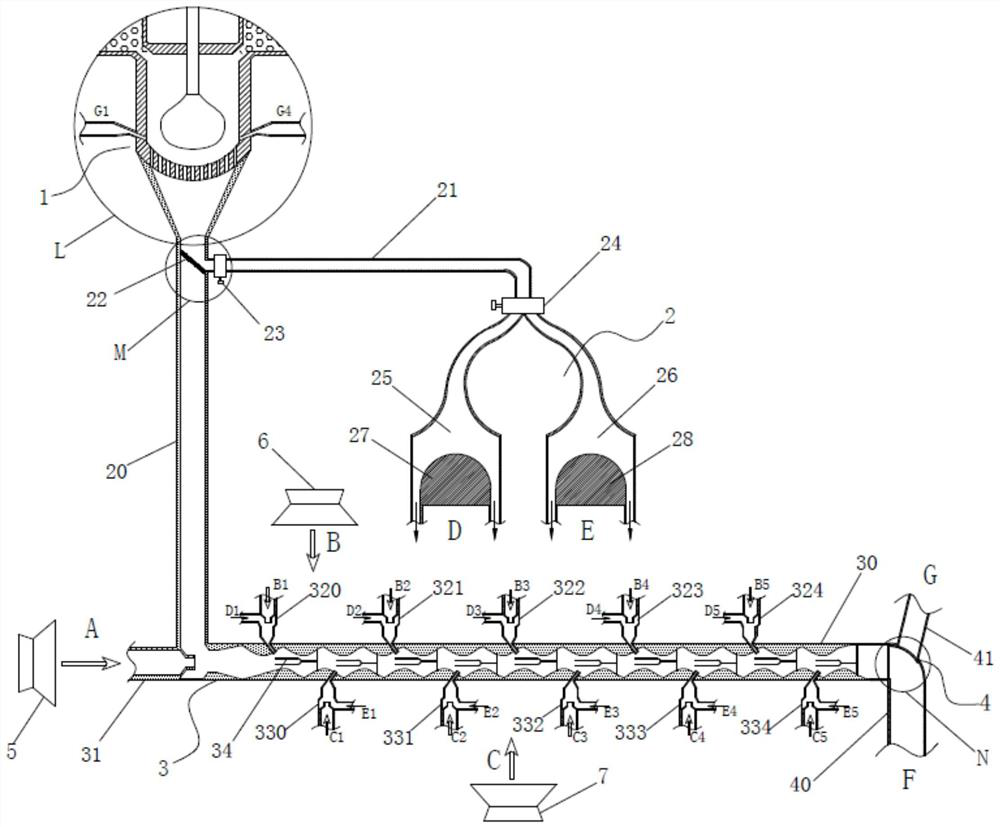

A kind of bismuth telluride thermoelectric material and preparation method thereof

ActiveCN112500164BHigh speedControllable powder compositionHigh volume manufacturingBismuth telluride

The invention belongs to the technical field of thermoelectric materials, and discloses a preparation method of a bismuth telluride thermoelectric material, comprising the following steps: step 1, according to the chemical formula X of N-type bismuth telluride material w / Bi 2 Te 2.7‑ w Se 0.3 Weigh Bi, Te and Se elemental powders as raw materials, or according to the chemical formula X of P-type bismuth telluride material w / Bi 0.5‑w Sb 1.5 Te 3 Weigh Bi, Sb and Te elemental powders as raw materials, X is the doping element, w is the stoichiometric ratio of the doping element X, and the range is 0≤w≤0.1; step 2, mix the above raw materials evenly and place High-energy ball milling is carried out in the ball milling tank of the plasma generator; step 3, the powder in the tank after ball milling is transferred to a sintering mold under an inert gas for sintering, and the sintering is carried out twice, and after cooling, a bismuth telluride thermoelectric material is obtained. The invention combines plasma ball milling and discharge plasma sintering technology to prepare high-performance bismuth telluride material for the first time. The method has the advantages of fast speed, controllable powder composition, low energy consumption and is suitable for mass production.

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS +1

A kind of raw material fine grinding method of direct oral decoction pieces

The invention discloses a fine grinding method for raw materials of direct oral decoction pieces, which has fewer procedures and simple operation, and does not need excessive drying and degreasing in advance; the high-speed airflow brings the drug particles to collide with the metal inner wall and the tuning fork, and the collision force is greater, crushing The effect is better; the high-speed airflow carrying the drug particles is staggered through the nozzles, making the movement of the drug particles more disordered, increasing the frequency of collisions, and using low-temperature nitrogen throughout the process to avoid drug oxidation and heat damage, and at the same time embrittle the raw material particles It can improve the crushing degree; the tuning fork will not produce sound waves of various frequencies after being collided, which can improve the Brownian motion of the decoction pieces powder, weaken the bonding phenomenon, and further improve the crushing effect.

Owner:桂林中南(亳州)药业科技有限公司

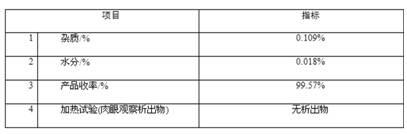

Porcelain sleeve assembling tool

ActiveCN106425999AImprove performance consistencyRealize building block dockingMetal-working hand toolsManufacturing technologyButt joint

The invention belongs to the technical field of tool manufacturing, and relates to a porcelain sleeve assembling tool. The assembling tool comprises a positioning body and a pushing device. The positioning body is provided with a T-shaped guide rail. The pushing device is composed of a push rod, a guide rod and a base plate. The assembling tool is applied to the product assembling process of a structure composed of a similar thermocouple, porcelain sleeve assembling which is completed manually is changed into machine production by means of the tool, the assembling time is short, only about 10 s is needed for assembling every porcelain sleeve, no intermittence or pause exists in assembling of multiple porcelain sleeves, continuous operation is achieved, and the production efficiency is multiple or even tens of times that of manual penetration. The porcelain sleeves are concentrically installed in a sleeve pipe hole, the centering precision reaches 0.05-0.1 mm, the phenomenon that porcelain sleeves are inclined when penetrated manually is changed, the porcelain sleeves are successfully compacted, building block type butt joint of the porcelain sleeves is achieved, and the phenomena of reworking, raw material scrapping and manual labor hour waste are avoided.

Owner:天津航空机电有限公司

An anti-shrinkage glaze protective coating for submerged nozzle slag line and preparation method thereof

The invention discloses a glaze-crawling-proof protection coating for an immersion type water gap slag line and a preparation method of the glaze-crawling-proof protection coating. The coating is prepared from a main material, water and dextrin; the main material is prepared from the following components in percentage by weight: 62 percent to 66 percent of tabular corundum, 15 percent to 17 percent of Suzhou clay, 3 percent to 5 percent of bentonite, 12 percent to 16 percent of active aluminum oxide and 0.5 percent to 1 percent of sodium silicate; the weight ratio of the water to the dextrin to the main material is (31 to 33):(0.6 to 0.8):100. The glaze-crawling-proof protection coating disclosed by the invention can be used for effectively preventing an anti-oxidization coating of the immersion type water gap slag line part from generating glaze crawling, so that the strength and anti-corrosion performance of the immersion type water gap slag line are improved, and the service life of an immersion type water gap can be prolonged for 2.5 hours to 3.5 hours.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com