Novel seedling grafting device and grafting method thereof

A grafting device and technology for seedlings, applied in the field of new-type seedling grafting devices, can solve the problems of large liquid loss, slow speed, affecting the quality of grafting, etc., and achieve the effects of avoiding liquid loss, overcoming manual operation, and improving grafting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

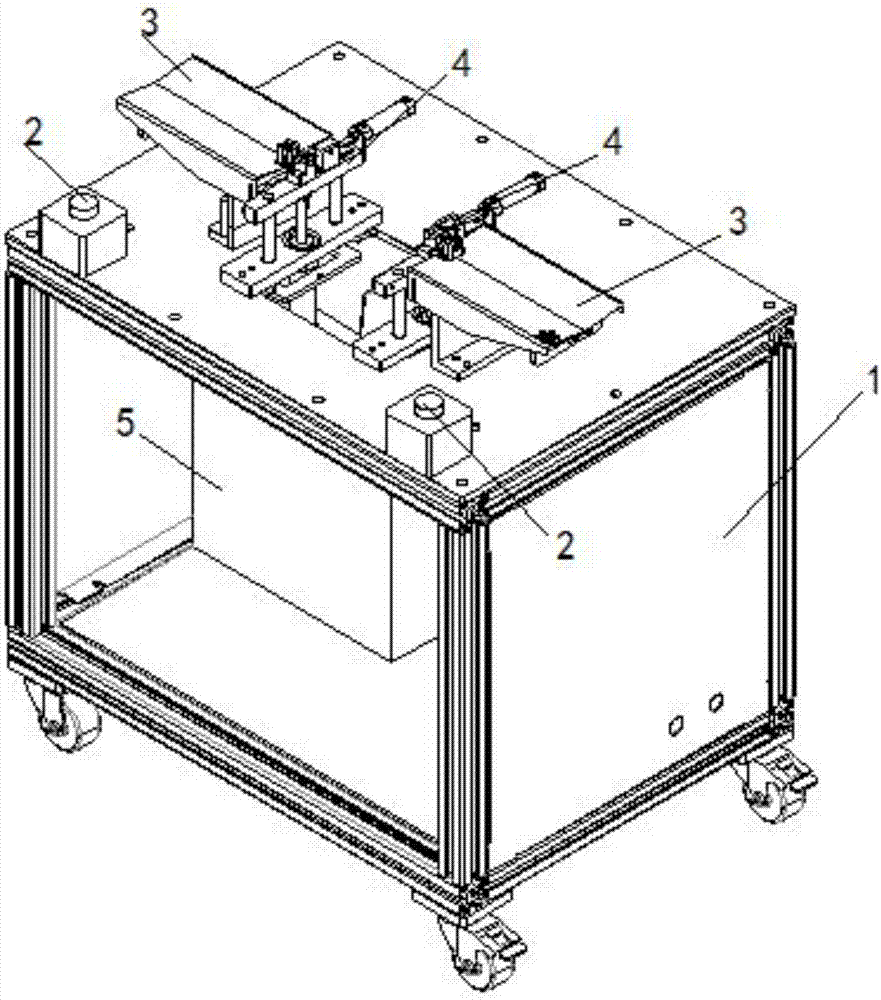

[0029] Such as figure 1 As shown, the novel rice shoot grafting machine device of the present invention includes: a frame 1, a start switch 2, two groups of clamping mechanisms 3, two shearing mechanisms 4, and a control system 5.

[0030] Such as Figure 4 As shown, the frame 1 includes a clamping mechanism mounting plate 14 .

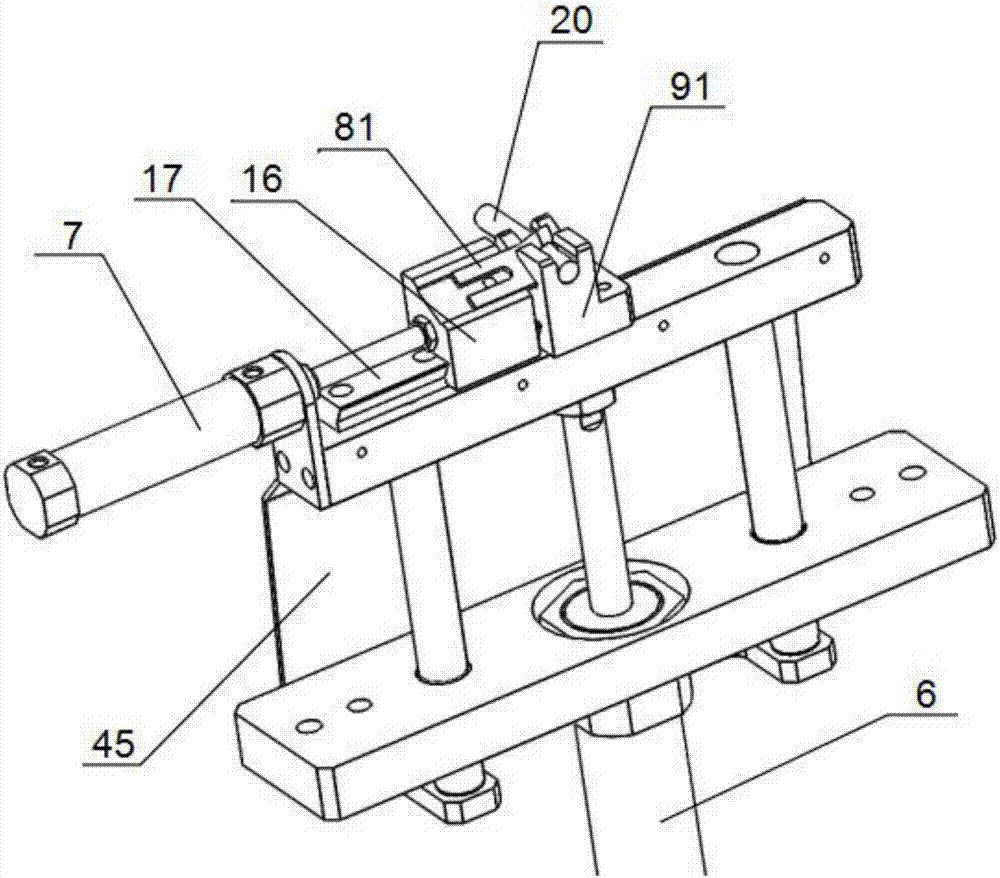

[0031] Such as figure 2 As shown, the shearing mechanism 4 includes: a jacking cylinder 6, a shearing cylinder 7, a blade 81, and a seedling placement groove 91.

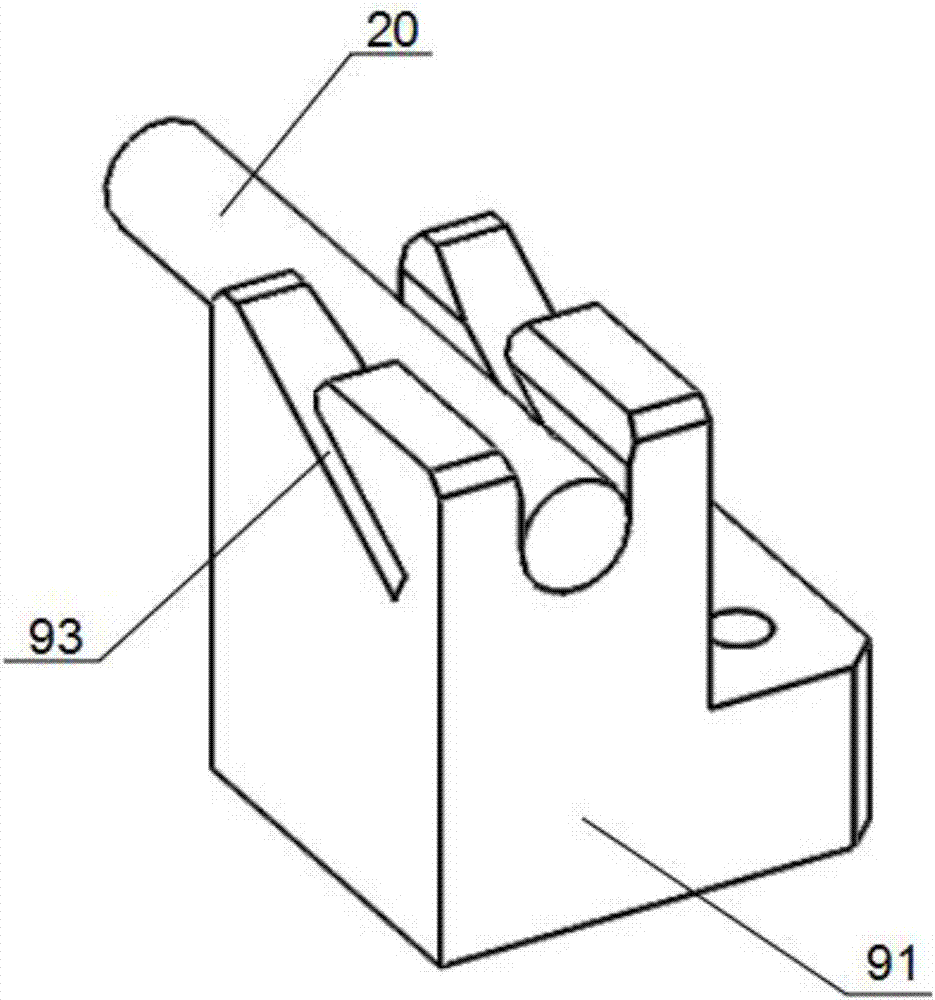

[0032] Such as image 3 Shown, there is a groove in the center of the rice shoot placing groove 91, and the opening 93 for the blade to pass is provided on the wall on both sides of the groove. The seedlings 20 are placed in the grooves.

[0033] Such as figure 2 Shown, shearing mechanism is provided with slideway 17 and slide block 16 between shearing cylinder 7 and rice shoot placing groove 91, slide block 16 is connected at the front end of shearing cylinder 7, slide block 16 is ...

Embodiment 2

[0046] The basic structure of this embodiment is the same as that of the first embodiment, the difference is that: in the cutting mechanism 4, a new blade shape is provided.

[0047] Such as Figure 5 As shown, the shearing mechanism 4 in the present embodiment includes a slide block 15, a V-shaped blade 82, and a seedling placement groove 92.

[0048] The V-shaped blade 82 is V-shaped. The V shape is connected on the slide block 15 across. Correspondingly, the seedling placement groove 92 also has a V-shaped opening for the V-shaped blade 82 to pass through so as to cut the seedlings.

[0049] The blades of the two sets of shearing mechanisms are arranged in a V-shape horizontally, and the V-shaped tips of the two blades are directed in the same direction, so that one of the two seedlings to be grafted is cut into a concave V-shape, and the other is cut into a convex V-shape. shaped tip to match the two together. Figure 5 shows the baffles set under the blades and seedli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com