Grafting knife for small plants

A grafting knife and plant technology, which is applied in the field of grafting of small plants, can solve problems such as injury, inconvenient wrapping, and reduced compactness between the epidermis and branches, and achieve the effect of high survival rate and fast grafting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

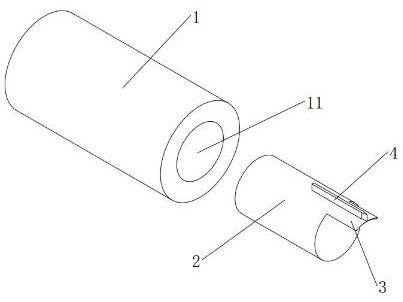

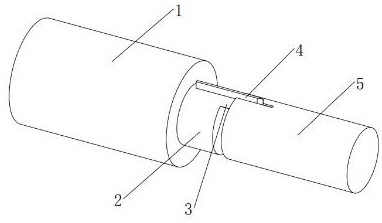

[0018] Such as figure 2 As shown, a grafting knife for small plants includes a handle 1, a connecting cylinder 2, a main blade 3 and an auxiliary blade 4, the main blade 3 can be processed from the connecting cylinder and formed integrally, and one end of the handle 1 is provided with A round hole 11, one end of the connecting cylinder 2 is inserted into the round hole 11, and the other end is left outside the round hole 11, the main blade 3 is located at the outer end of the connecting cylinder 2, and the main blade 3 extends outward along the outer edge of the connecting cylinder 2, The main blade 3 is arc-shaped and is consistent with the arc of the connecting cylinder 2; the secondary blade 4 is vertically placed on the outer wall of the main blade 3, and the blades of the main blade 3 and the secondary blade 4 are located at the outermost end (i.e. figure 2 center right).

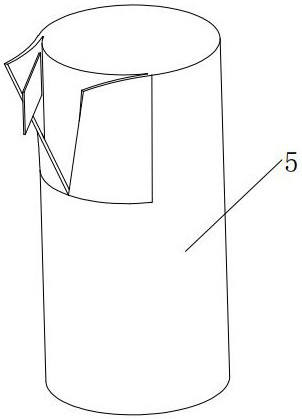

[0019] Such as image 3 As shown, the plant 5 is first cut flat with scissors, and then the end...

Embodiment 2

[0037] Such as Figure 4 As shown, the specific implementation method is the same as that of Example 1, the difference is that: the opposite end of the auxiliary blade 4 is provided with a flat block 41, and the connecting cylinder 2 corresponding to the block 41 is provided with a flat groove 21; An arc-shaped groove-shaped buckle 44 is provided on the outside of the locking block 41 of the auxiliary blade 4 , and a cylinder matching the buckle 44 is arranged in the flat groove 21 . When installing, the sub-blade can be inserted at a slightly inclined angle (the size in the picture is for the convenience of display, not the actual real size, there is no problem during installation), the buckle is restricted by the cylinder, and then the opposite side of the buckle is forced into the flat concave The groove is fixed to prevent the sub-blade from falling out, so that the positioning of the sub-blade is more accurate and the card position is more in place. After the block of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com