Fabrication method of mesa photodetector

A technology for photodetectors and manufacturing methods, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems affecting device responsivity, dark current, quantum efficiency reliability and operating speed, increase surface recombination rate and surface leakage current , surface oxidation and other issues, to achieve the effect of reducing the probability of formation, reducing dark current, and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

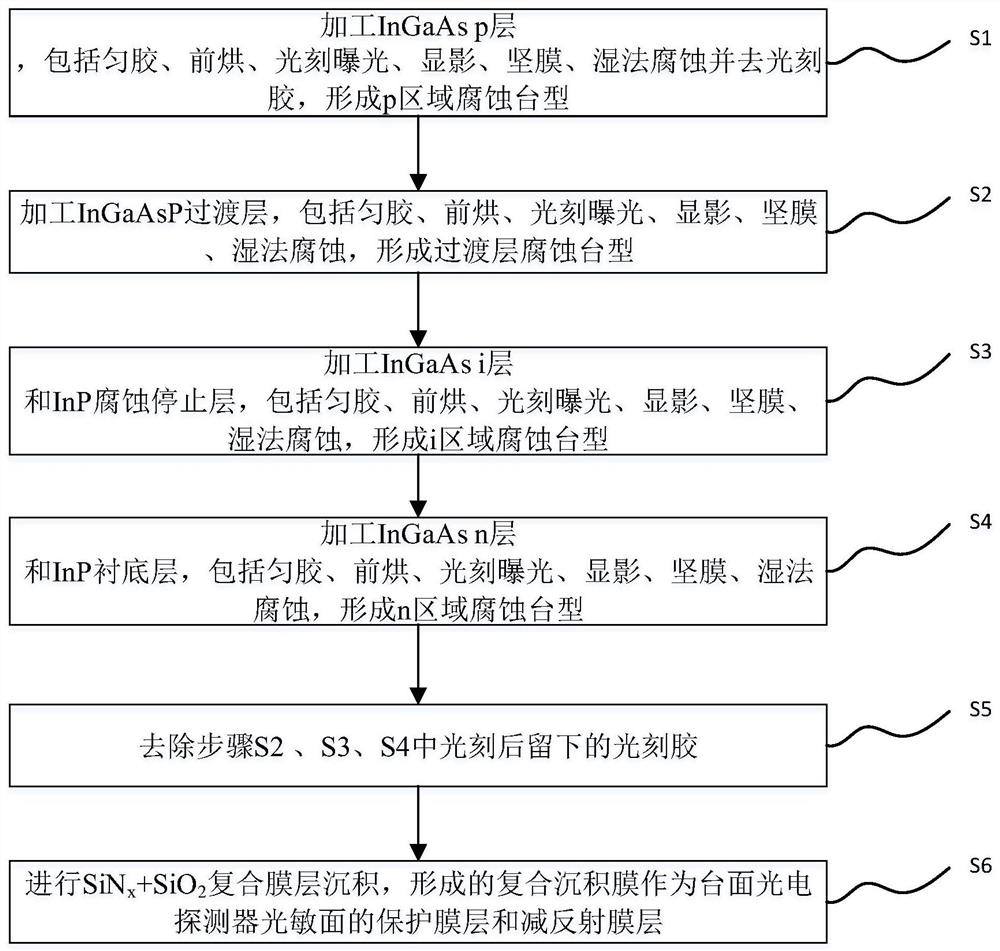

[0066] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

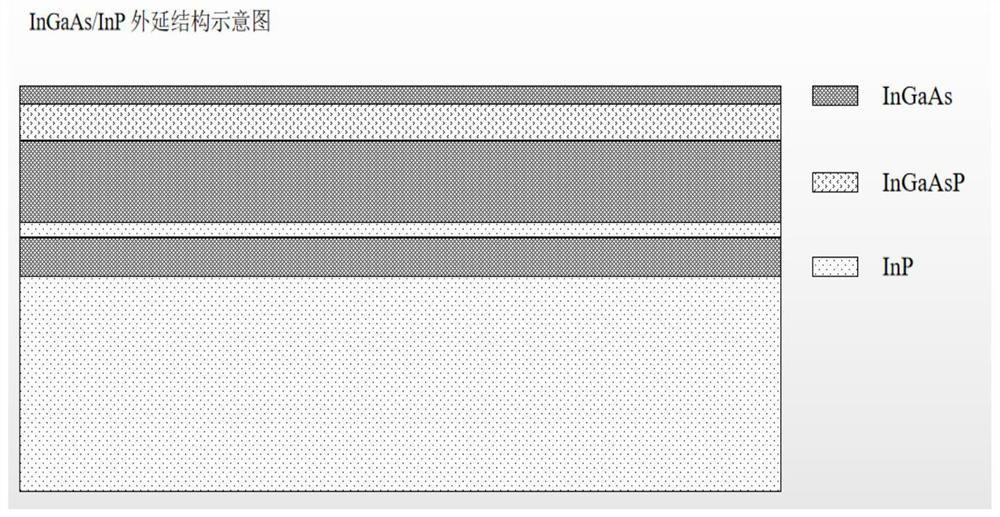

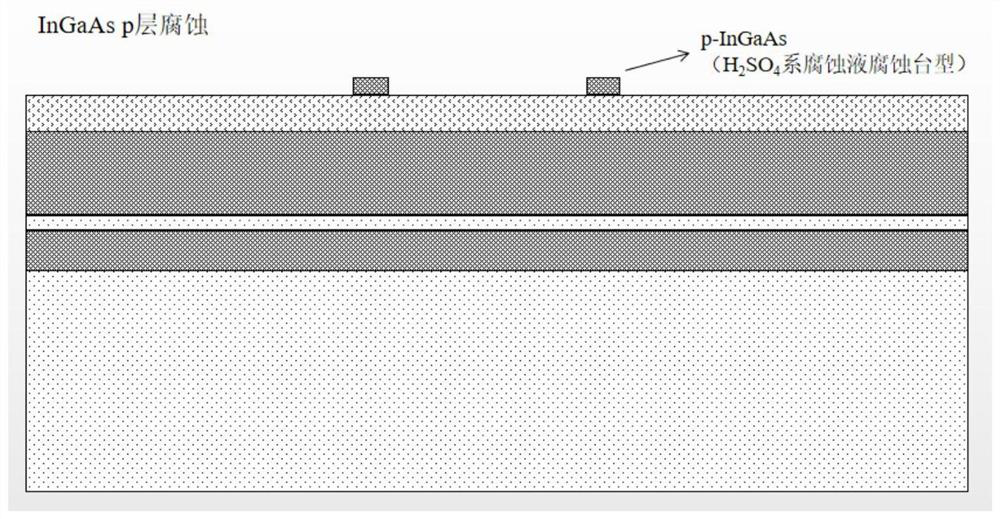

[0067] The epitaxial structure of the mesa-type InGaAs / InP PIN photodetector processed in the embodiment of the present invention is as attached figure 2 As shown, from top to bottom are:

[0068] (1) InGaAs layer, PIN structure p layer, thickness is about 0.1-0.3 μm.

[0069] (2) InGaAsP layer, a transition layer, with a thickness of about 0.3-0.5 μm.

[0070] (3) InGaAs layer, i-layer of PIN structure, with a thickness of about 2-3 μm.

[0071] (4) InP layer, the corrosion stop layer, the thickness is about 30nm.

[0072] (5) InGaAs layer, an n-layer of PIN structure, with a thickness of abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com