Process for continuously producing anthranilic acid

A technology of anthranilic acid and phthalimide, which is applied in the field of continuous production of anthranilic acid, can solve problems such as low equipment utilization, low production efficiency, and back-mixing of raw materials, so as to improve production efficiency and reduce energy consumption. The effect of reducing consumption and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Add 200kg of phthalimide, 600kg of pure water, and 527kg of 32% sodium hydroxide solution into phthalimide alkalization reaction kettle 1, start stirring, turn on and adjust the motor speed to make the material reach a turbulent state , the material gradually dissolves and the solution becomes clear;

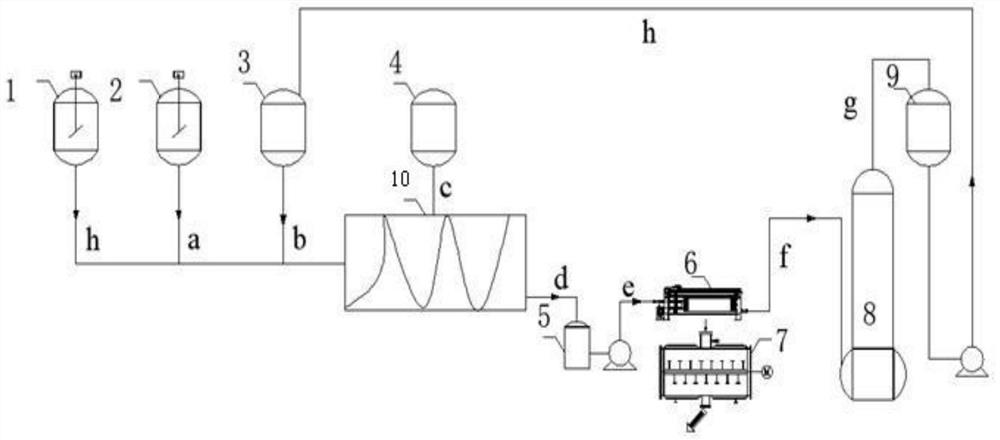

[0031] (2), hydrogen peroxide storage tank / 1, concentrated hydrochloric acid storage tank 2, phthalimide alkalization reaction kettle 3, hydrochloric acid storage tank 4, open the corresponding bottom valve, through the interlocking control of the flow meter and the valve, respectively Enter the microchannel reactor 10 according to a certain flow rate, ensure that the reaction solution of the mixed solution of imine phthalimide basification solution, hydrogen peroxide and hydrochloric acid is 45s in the residence time of the microchannel, open the refrigerant valve of the reactor, control The temperature of the solution is 5°C, and the pH of the acidified solution pro...

Embodiment 2

[0036] (1) Add 200kg of phthalimide, 600kg of pure water, and 527kg of 32% sodium hydroxide solution into phthalimide alkalization reaction kettle 1, start stirring, turn on and adjust the motor speed to make the material reach a turbulent state , the material gradually dissolves and the solution becomes clear;

[0037] (2), 32% hydrogen peroxide storage tank 1, concentrated hydrochloric acid storage tank 2, phthalimide alkalization reaction kettle 1, hydrochloric acid storage tank 3, open the corresponding bottom valve, through the interlocking control of the flow meter and the valve, Enter microchannel reactor 10 respectively according to certain flow rate, guarantee that the reaction solution of imine phthalimide alkalization liquid, sodium hypochlorite solution is 60s in microchannel residence time, open the refrigerant valve of reactor, control the temperature of solution is 8°C, and the pH of the acidified solution produced is about 2.2, and enters the temporary storage ...

Embodiment 3

[0042] (1) Add 200kg of phthalimide, 600kg of pure water, and 538kg of 32% sodium hydroxide solution into phthalimide alkalization reaction kettle 1, start stirring, turn on and adjust the motor speed to make the material reach a turbulent state , the material gradually dissolves and the solution becomes clear;

[0043] (2) Hydrogen peroxide storage tank 1 concentrated hydrochloric acid storage tank 2, phthalimide alkalization reaction kettle 3, hydrochloric acid storage tank / 4 open the corresponding bottom valve, through the interlocking control of the flow meter and the valve, respectively according to a certain The flow rate enters the microchannel reactor 10 to ensure that the residence time of the reaction solution of the imine phthalimide alkalization solution and the sodium hypochlorite solution in the microchannel is 60s, and the refrigerant valve of the reactor is opened to control the temperature of the solution to be 8°C , the pH of the acidified solution produced i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com