Analysis method of material failure crack source

An analysis method and material failure technology, applied in the direction of analyzing materials, instruments, measuring devices, etc., can solve the problems of wear, determine the crack source, cannot observe the crack source extension line, scallop line, etc., to avoid serious wear, reduce Interfere, avoid exposure to oxidative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] An analysis method for a material failure crack source, comprising:

[0077] S1. Take 4 forged blanks made of 60Si2Mn from the same batch as samples. The processing technology of the forged blank is blanking, heating and then forging, and there are cracks at the end after the forging is completed.

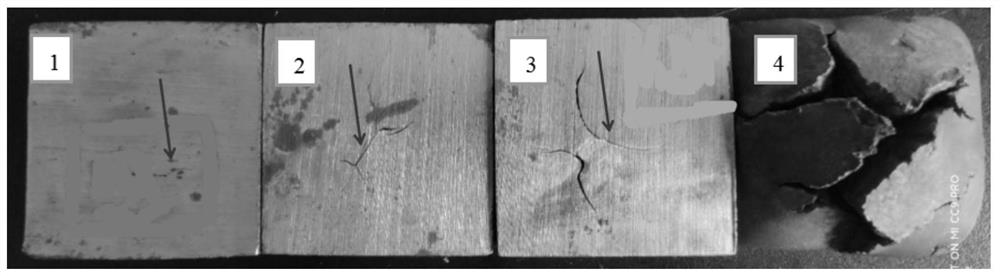

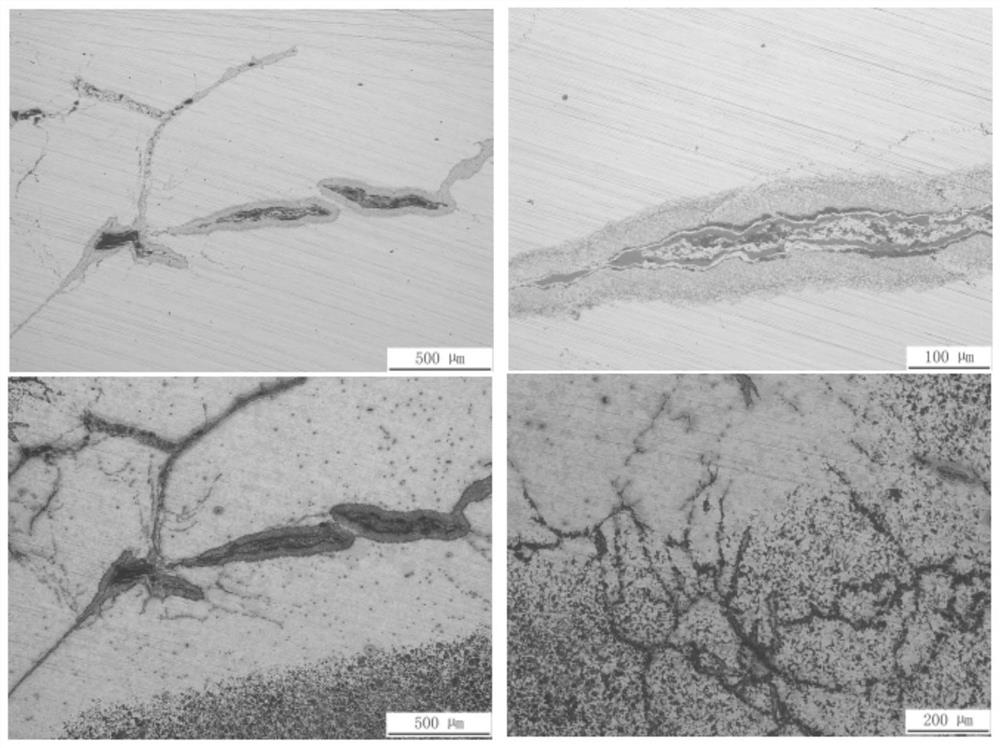

[0078] Among them, a forged blank was forged to complete a sample for one forging cycle, and a fractured part with severe cracking at the end was obtained, as shown in figure 1 shown. The part where the end of the sample is cracked is taken as the failure sample, and one cycle of its forging is the failure cycle.

[0079] The other three samples were forged for 1 / 4 forging cycle, 2 / 4 forging cycle and 3 / 4 forging cycle respectively, and then the ends were cut off, respectively used as intermediate samples, and numbered as sample No. 1 in sequence , No. 2 sample and No. 3 sample. And number the broken part as No. 4 sample. No. 1 sample, No. 2 sample, No. 3 sample and No....

Embodiment 2

[0094] An analysis method for a material failure crack source, comprising:

[0095] S1. Take a round steel with a material of GCr15 (YF) and a diameter of 42 mm as a sample. The processing technology of this sample is blanking, turning chips, heat treatment, abrasives, and then a mandrel is obtained.

[0096] Among them, the rod body that is abnormally broken after the mandrel is used is used as the broken part, such as Figure 5 ~ Figure 7 As shown in Fig. 1, the height of the fracture at the end of the sample fluctuates seriously, and the crack source is more than one, which is multi-source cracking. The fracture at the end of the sample is taken as the failure sample.

[0097] Take a sample at a distance of 10mm from the fracture, numbered as sample No. 5, such as Figure 8 shown.

[0098] Take a sample at a distance of 20mm from the fracture, numbered as sample No. 6, such as Figure 9 shown.

[0099] S2. Observe No. 5~6 samples, please refer to Figure 8 , No. 5 sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com