Preparation method for wrapping surfaces of ceramic particles with metal

A technology of ceramic particles and packaging, applied in metal processing equipment, metal material coating technology, transportation and packaging, etc., can solve the problem of insufficient wettability between ceramic and metal, weak bonding performance between metal and ceramic, and low hardness of metal coating. problems, to achieve the effect of improving bonding performance, low wear rate and high micro Vickers hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

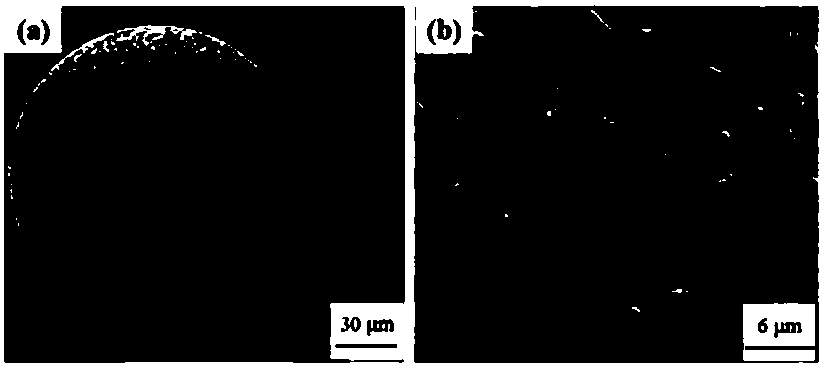

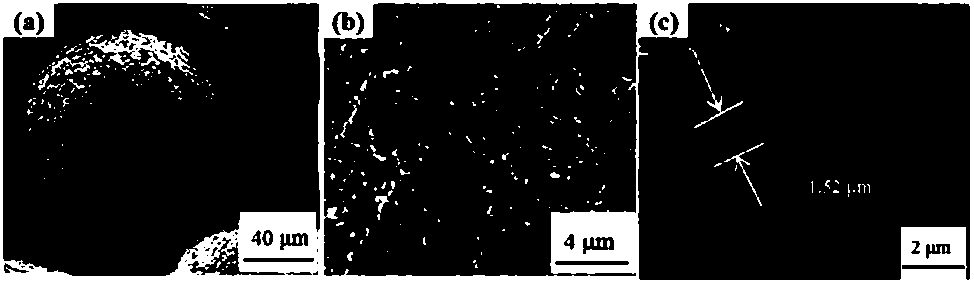

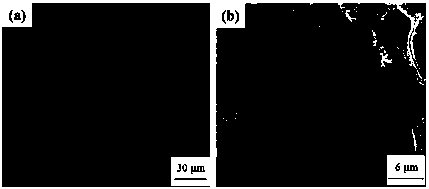

Image

Examples

Embodiment 1

[0077] A preparation method for coating metal on the surface of ceramic particles, the steps are as follows:

[0078] (1) TiB 2 Pour the ceramic powder into the alkaline solution, ultrasonically clean it for 45 minutes, wash it with deionized water until it is neutral, and then put it in a drying oven at 120°C to dry;

[0079] (2) TiB 2 Pour the ceramic powder into the acid solution, ultrasonically clean it for 60 minutes, wash it with deionized water until it is neutral, and then put it in a drying oven to dry at 110°C;

[0080] (3) According to mass ratio, TiB 2 Ceramic powder and Ti powder, NH 4 Cl, TiH 2 =85:15:10:15 After uniform mixing, put it into a horizontal tube furnace, and conduct a vacuum reaction treatment at 850°C for 3 hours;

[0081] (4) Sieve the ceramic powder with a 800-mesh sieve, wash with absolute ethanol and deionized water for 4 times, and then put it in a drying oven for drying at 120°C;

[0082] (5) According to mass ratio, TiB 2 Ceramic powde...

Embodiment 2

[0086] A preparation method for coating metal on the surface of ceramic particles, the steps are as follows:

[0087] (1) Pour the WC ceramic powder into the alkaline solution, ultrasonically clean it for 60 minutes, wash it with deionized water until it is neutral, and then put it in a drying oven to dry at 150°C;

[0088] (2) Pour the WC ceramic powder into the acid solution, ultrasonically clean it for 90 minutes, wash it with deionized water until it is neutral, and then put it in a drying oven to dry at 120°C;

[0089] (3) According to the mass ratio, WC ceramic powder and Ti-Ni mixed powder, NH 4 Cl, TiH 2 -NiH mixed powder=95:20:15:25, mixed evenly and put into a horizontal tube furnace, 950°C vacuum reaction treatment for 2h;

[0090] (4) Sieve the ceramic powder with a 1250-mesh screen, wash with absolute ethanol and deionized water for 7 times, and then put it into a drying oven for drying at 150°C;

[0091] (5) According to the mass ratio, WC ceramic powder and T...

Embodiment 3

[0095] A preparation method for coating metal on the surface of ceramic particles, the steps are as follows:

[0096] (1) According to the mass ratio, Si 3 N 4 with Al 2 o 3 Ceramic powder = 35:65 mixed evenly, and poured into the alkaline solution, after ultrasonic cleaning for 90 minutes, washed with deionized water until neutral, and then dried in a drying oven at 120°C;

[0097] (2) Si 3 N 4 -Al 2 o 3 The ceramic powder is poured into the acid solution, ultrasonically cleaned for 30 minutes, washed with deionized water until neutral, and then dried in a drying oven at 150°C;

[0098] (3) According to the mass ratio, Si 3 N4 -Al 2 o 3 Ceramic powder and Ti-Ni mixed powder, NH 4 Cl, TiH 2 Mixed powder = 90:25:20:15, mix evenly and put it into a horizontal tube furnace, and conduct a vacuum reaction treatment at 1050°C for 5 hours;

[0099] (4) Sieve the ceramic powder with a 1000-mesh sieve, wash with absolute ethanol and deionized water for 5 times, and then pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com