Heat treatment method for reducing block-shaped Nb in Inconel783 alloy

A heat treatment method and alloy technology, which is applied in the field of alloy heat treatment, can solve problems such as hidden dangers in safe operation of equipment, reduction in bolt performance and service life, and damage to organizational continuity, so as to improve slip resistance and reduce the probability of inclusion formation , The effect of improving the uniformity of the tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

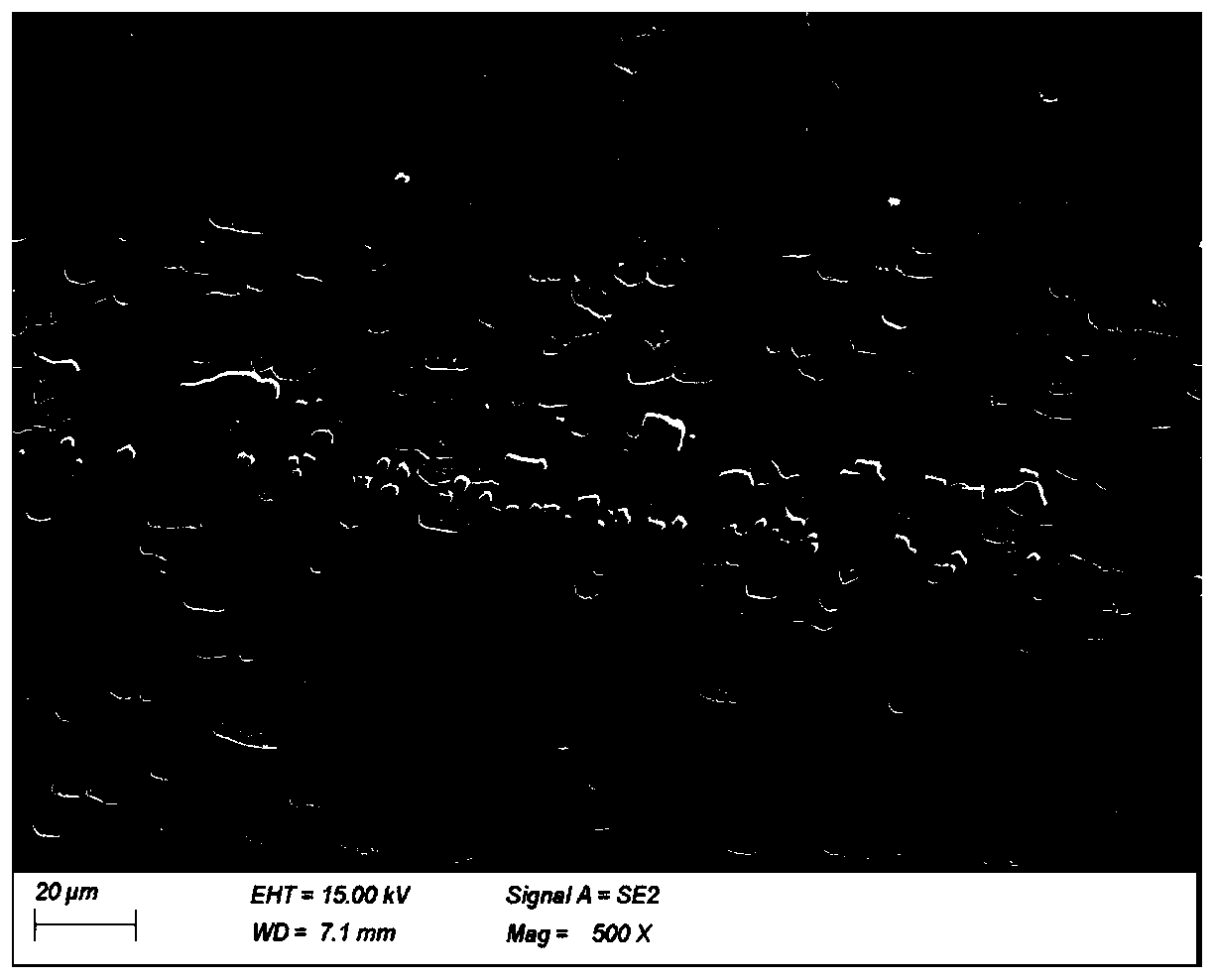

Image

Examples

Embodiment 1

[0044] A heat treatment method for reducing bulk Nb in Inconel783 alloy

[0045] (1) Solution treatment: heat the sample in a KSL-1400X box-type resistance furnace, raise the temperature to 1150°C at a heating rate of 5°C / min, keep it warm for 60min, and cool it to room temperature with soft water; using soft water will not damage the material Corrosion and scaling inside;

[0046] (2) β aging treatment: heat the sample after solid solution treatment to 840°C at a heating rate of 5°C / min, and keep it warm for 4h;

[0047] (3) γ' aging treatment: heat and cool the sample after β aging treatment to 720°C, keep it for 8 hours, cool it in a furnace at 8°C / min to 630°C, keep it for 8 hours, and then air cool to room temperature.

Embodiment 2

[0049] A heat treatment method for reducing bulk Nb in Inconel783 alloy

[0050] (1) Solution treatment: heat the sample in a KSL-1400X box-type resistance furnace, raise the temperature to 1150°C at a heating rate of 5°C / min, keep it warm for 60min, and cool it to room temperature with soft water;

[0051] (2) β aging treatment: heat the sample after solid solution treatment to 840°C at a heating rate of 5°C / min, and keep it warm for 6h;

[0052] (3) γ' aging treatment: heat and cool the sample after β aging treatment to 720°C, keep it for 8 hours, cool it in a furnace at 8°C / min to 630°C, keep it for 8 hours, and then air cool to room temperature.

Embodiment 3

[0054] A heat treatment method for reducing bulk Nb in Inconel783 alloy

[0055] (1) Solution treatment: heat the sample in a KSL-1400X box-type resistance furnace, raise the temperature to 1140°C at a heating rate of 5°C / min, keep it warm for 50min, and cool it to room temperature with soft water;

[0056] (2) β aging treatment: heat the sample after solid solution treatment to 830°C at a heating rate of 5°C / min, and keep it warm for 6h;

[0057] (3) γ' aging treatment: heat up and cool the β-aging sample to 710°C, keep it for 6h, cool it in a furnace at 5°C / min to 620°C, keep it for 6h, and then air cool to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact energy | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com