Type-II superlattice structure based on indium arsenide and preparation method

A technology of superlattice and indium arsenide, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problem of low superlattice growth temperature, achieve growth temperature increase, improve material performance, avoid The effect of frequent switching of As valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

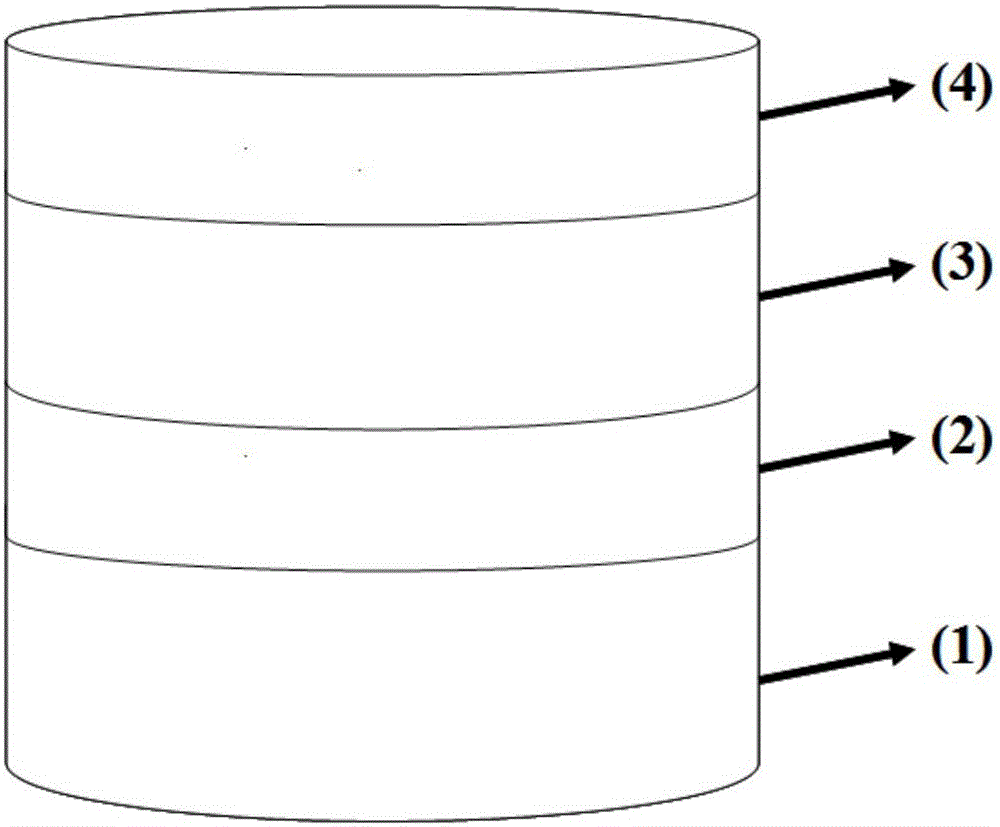

[0025] According to the content of the invention, we have prepared a type II superlattice material, and its specific structure is:

[0026] The thickness of the InAs layer 1 is 2.1 nm;

[0027] The thickness of the GaAs layer 2 is 0.0 nm;

[0028] GaAs x Sb 1-x The thickness of layer 3 is 2.1 nm, and the ratio x is 0.09;

[0029] The thickness of the GaAs layer 4 is 0.0 nm.

Embodiment 2

[0031] According to the content of the invention, we prepared a second type II superlattice material, and its specific structure is:

[0032] The thickness of the InAs layer 1 is 6.6 nm;

[0033] The thickness of the GaAs layer 2 is 0.1 nm;

[0034] GaAs x Sb 1-x The thickness of layer 3 is 2.7 nm, and the ratio x is 0.02;

[0035] The thickness of the GaAs layer 4 is 0.1 nm.

Embodiment 3

[0037] According to the content of the invention, we prepared a third type II superlattice material, and its specific structure is:

[0038] The thickness of the InAs layer 1 is 10.5 nm;

[0039] The thickness of the GaAs layer 2 is 0.15 nm;

[0040] GaAs x Sb 1-x The thickness of layer 3 is 3.6 nm, and the ratio x is 0.01;

[0041] The thickness of the GaAs layer 4 is 0.15 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com