Long-wavelength LED epitaxial wafer, chip and preparation method thereof

An LED chip, long-wavelength technology, used in electrical components, circuits, semiconductor devices, etc., can solve problems such as increased cost, increased manufacturing difficulty, environmental pollution, etc., to achieve the effect of improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1 0

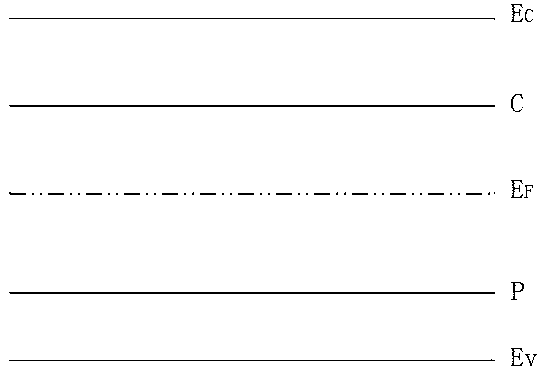

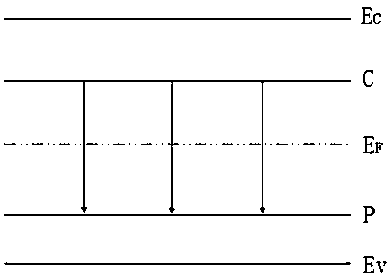

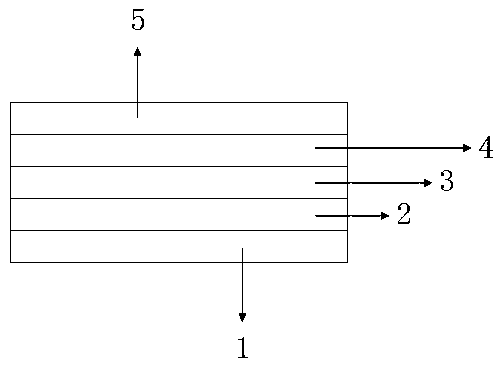

[0053] The long-wavelength LED epitaxial barrier wafer of the present invention such as Figure 4 As shown, including: sapphire substrate 1, buffer layer 2, n-type CaN3, quantum well 41, p-type CaN5, the prior art quantum well 4 has been improved, and the quantum well is AlxInyCa(1-x-y)N quantum well, x=0.1, y=0.4. The organic growth source containing C is introduced into the reaction chamber to participate in the growth of quantum wells under the catalysis of Cl2 or HCl. The growth temperature is controlled between 700°C and 990°C, and the temperature difference w between the well and epitaxy growth is controlled at about 80°C to control the quantum well growth. The well growth rate is about 0.6A / sec, the quantum wells are more than 7 pairs, and the concentration range of C in the quantum wells is 10 16 ——10 20 cm -3 , grow P-type CaN5 on the quantum well 41, and control the total thickness of the epitaxial barrier crystal layer wi...

Embodiment 2

[0055] The long-wavelength LED epitaxial barrier wafer of the present invention such as Figure 5 Shown, comprise: sapphire substrate 1, buffer layer 2, n-type CaN3, AlxInyCa (1-x-y) N quantum well comprises (quantum well 41, quantum well 42), p-type CaN5, carries out to prior art quantum well 4 Improvement is made to make quantum wells greater than or equal to 7 pairs. Quantum well 42 is the first, second and third pair of quantum wells wherein there is no deposition distribution of C. Quantum well 41 is the quantum well after the third pair of quantum wells, where x= 0.1, y=0.5, when the fourth pair of quantum wells grows, the trimethylaluminum source enters the reaction chamber to participate in the growth of quantum wells under the catalysis of Cl2 or HCl, and the growth temperature is controlled between 700°C and 990°C, where the wells and The epitaxy growth temperature difference w is controlled at about 70°C, and the growth rate is controlled at about 0.5A / sec, so that ...

Embodiment 3

[0057] like Figure 4 As shown, the long-wavelength LED epitaxial barrier wafer preparation method of the present invention comprises;

[0058] a Put the sapphire substrate 1 into the MOCVD reaction chamber;

[0059] b Epitaxial growth buffer layer 2 and n-type CaN3 on sapphire substrate 1;

[0060] c After growing n-type CaN3 in the epitaxial barrier crystal, start to grow AlxInyCa(1-x-y)N quantum well, where x=0.23, y=0.51. Control the epitaxial growth temperature at about 860°C, feed trimethylgallium as the gallium source in the reaction chamber, and feed chlorine gas as the catalyst at the same time, control the growth rate of the quantum well to about 0.6A / sec, and the growth temperature difference between the well and the epitaxial is about 55°C , the concentration range of C in the quantum well 41 is 10 17 cm -3 On the left and right, there are C-stacked multi-quantum wells 41 distributed in the growth of epitaxial barrier crystals, and the number of quantum wells 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com