Type II superlattice structure and preparation method based on arsenic valve switch

A superlattice and switching technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, nanotechnology, etc., can solve the problems of unstable As pressure and uneven composition of superlattice materials, so as to reduce the formation probability, The effect of saving material growth time and saving stable time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

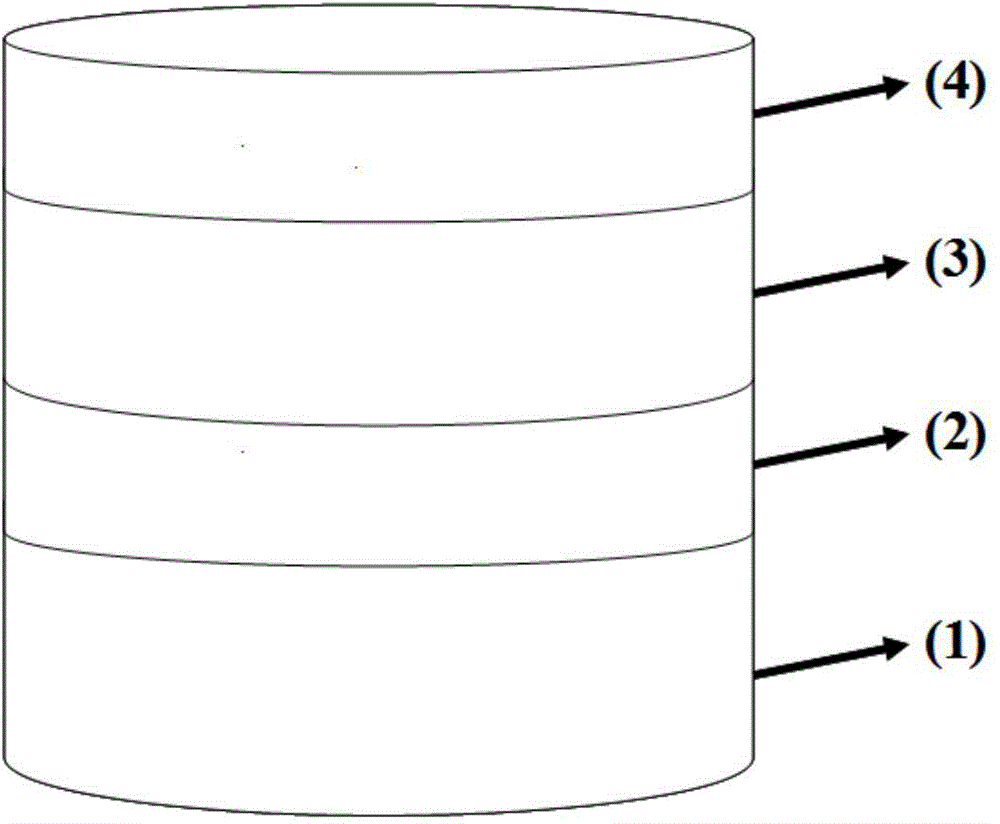

[0023] According to the content of the invention, we have prepared a type II superlattice material, the specific structure of which is:

[0024] GaAs x Sb 1-x Layer (1) has a thickness of 1.2 nm and a composition x of 0.01;

[0025] InAs y1 Sb 1-y1 Layer (2) has a thickness of 0.17 nm and a component y1 of 0.1;

[0026] The thickness of the InAs layer (3) is 2.4nm;

[0027] InAs y2 Sb 1-y2 Layer (4) has a thickness of 0.17 nm and a composition y2 of 0.65.

Embodiment 2

[0029] According to the content of the invention, we have prepared the second type II superlattice material, and its specific structure is:

[0030] GaAs x Sb 1-x Layer (1) has a thickness of 2.1 nm and a composition x of 0.015;

[0031] InAs y1 Sb 1-y1 Layer (2) has a thickness of 0.21 nm and a component y1 of 0.13;

[0032] The thickness of the InAs layer (3) is 3.6nm;

[0033] InAs y2 Sb 1-y2 Layer (4) has a thickness of 0.21 nm and a composition y2 of 0.85.

Embodiment 3

[0035] According to the content of the invention, we have prepared the third type II superlattice material, the specific structure of which is:

[0036] GaAs x Sb 1-x Layer (1) has a thickness of 1.8 nm and a composition x of 0.02;

[0037] InAs y1 Sb 1-y1 Layer (2) has a thickness of 0.23 nm and a component y1 of 0.25;

[0038] The thickness of the InAs layer (3) is 4.8nm;

[0039] InAs y2 Sb 1-y2 Layer (4) has a thickness of 0.23 nm and a composition y2 of 0.9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com