Method for increasing service life of aluminium alloy spot-welding electrode

A spot welding electrode, aluminum alloy technology, applied in welding equipment, resistance welding equipment, metal processing equipment and other directions, can solve the problem of insignificant effect, and achieve the effect of low cost, easy realization and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

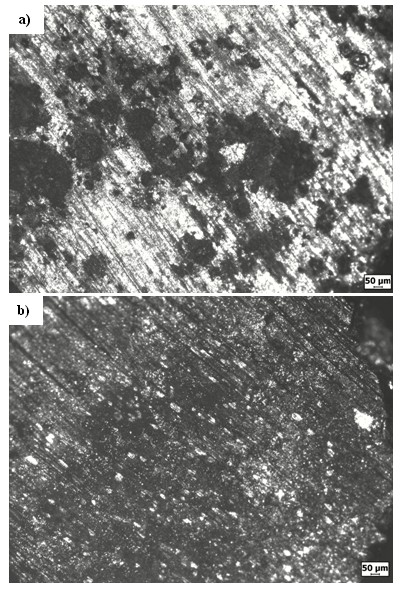

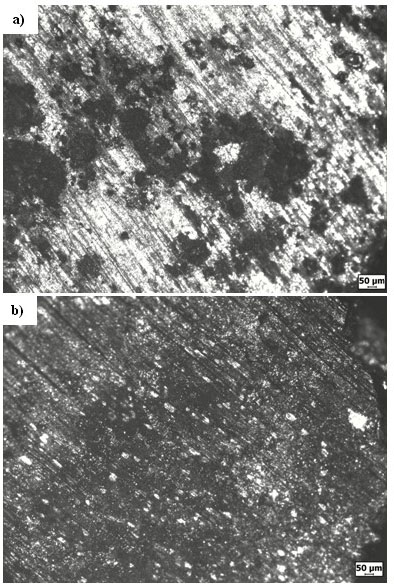

Embodiment 1

[0018] The thickness of the 2024 aluminum alloy plate to be welded is 0.5mm, using 800 # Grind the contact part of the aluminum plate to be welded with the electrode with sandpaper or a grinding wheel until the oxide film on the surface is removed and the wear debris is removed, and the part of the ground aluminum alloy plate that is in contact with the electrode is coated with graphite-oil paint, graphite-oil paint, etc. 20W-30 engine oil is used as a dispersant, which contains 2wt% of flake graphite, and the graphite particle size is 0.2μm. Then the electrode is brought into contact with the aluminum alloy plate to be welded at a moving speed of 1mm / s, and the aluminum alloy plate to be welded is clamped in the Between the spot welding electrodes, current spot welding is used, using a capacitor voltage of 200V, a welding current of 8000A, a welding time of 0.04s, and an electrode pressure of 500N. After completion, change to another spot to be welded and repeat the above oper...

Embodiment 2

[0021] The thickness of the LF6 aluminum alloy plate to be welded is 0.8mm, using 1000 # Grind the contact part of the aluminum plate to be welded with the electrode with sandpaper or a grinding wheel until the oxide film on the surface is removed and the wear debris is removed, and the part of the ground aluminum alloy plate that is in contact with the electrode is coated with graphite-oil paint, graphite-oil paint, etc. 10W-40 engine oil is used as a dispersant, which contains 4wt% flake graphite, and the graphite particle size is 0.8μm. Then the electrode is brought into contact with the aluminum alloy plate to be welded at a moving speed of 30mm / s, and the aluminum alloy plate to be welded is clamped in the Between the spot welding electrodes, conduct current spot welding, adopt capacitive voltage 300V, welding current 15000A, welding time 0.02s, electrode pressure 1200N, change to another spot to be welded after completion, repeat the above operation 600 times, the surface...

Embodiment 3

[0023] The thickness of the 6061 aluminum alloy plate to be welded is 1.2mm. Use 1000 # Grind the contact part of the aluminum plate to be welded with the electrode with sandpaper or a grinding wheel until the oxide film on the surface is removed and the wear debris is removed, and the part of the ground aluminum alloy plate that is in contact with the electrode is coated with graphite-oil paint, graphite-oil paint, etc. 15W-50 engine oil is used as a dispersant, which contains 5wt% flake graphite, and the graphite particle size is 1.2μm. Then the electrode is brought into contact with the aluminum alloy plate to be welded at a moving speed of 60mm / s, and the aluminum alloy plate to be welded is clamped in the Between the spot welding electrodes, conduct current spot welding, use a capacitor voltage of 350V, a welding current of 30000A, a welding time of 0.03s, and an electrode pressure of 2000N. After completion, replace another spot to be welded. Repeat the above operation 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com