Method for preparing gallium-nitride-based photoelectric detector based on graphene insertion layer structure

A photodetector and gallium nitride-based technology, applied in the field of microelectronics, can solve problems such as increased dark current of devices, poor quality of nitride materials, and reduced quality of gallium nitride, so as to increase growth temperature, improve quality, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

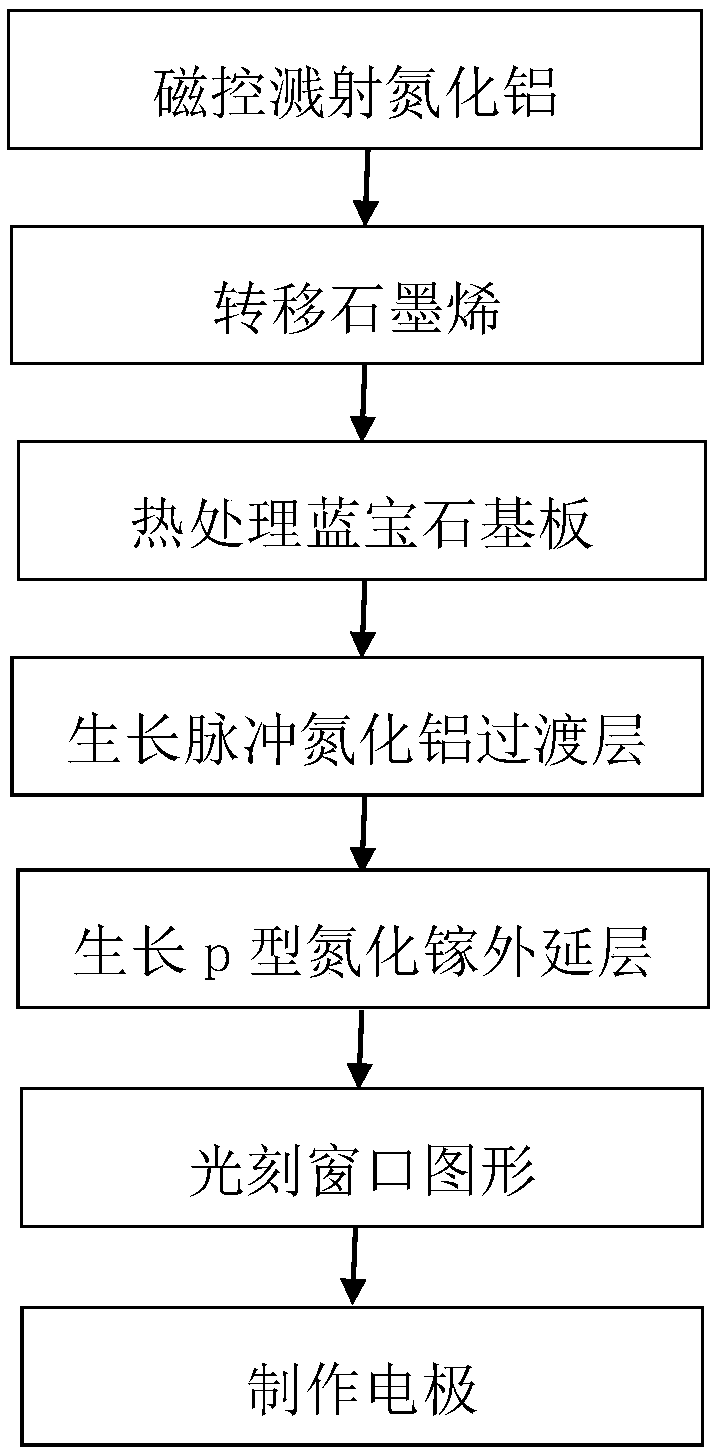

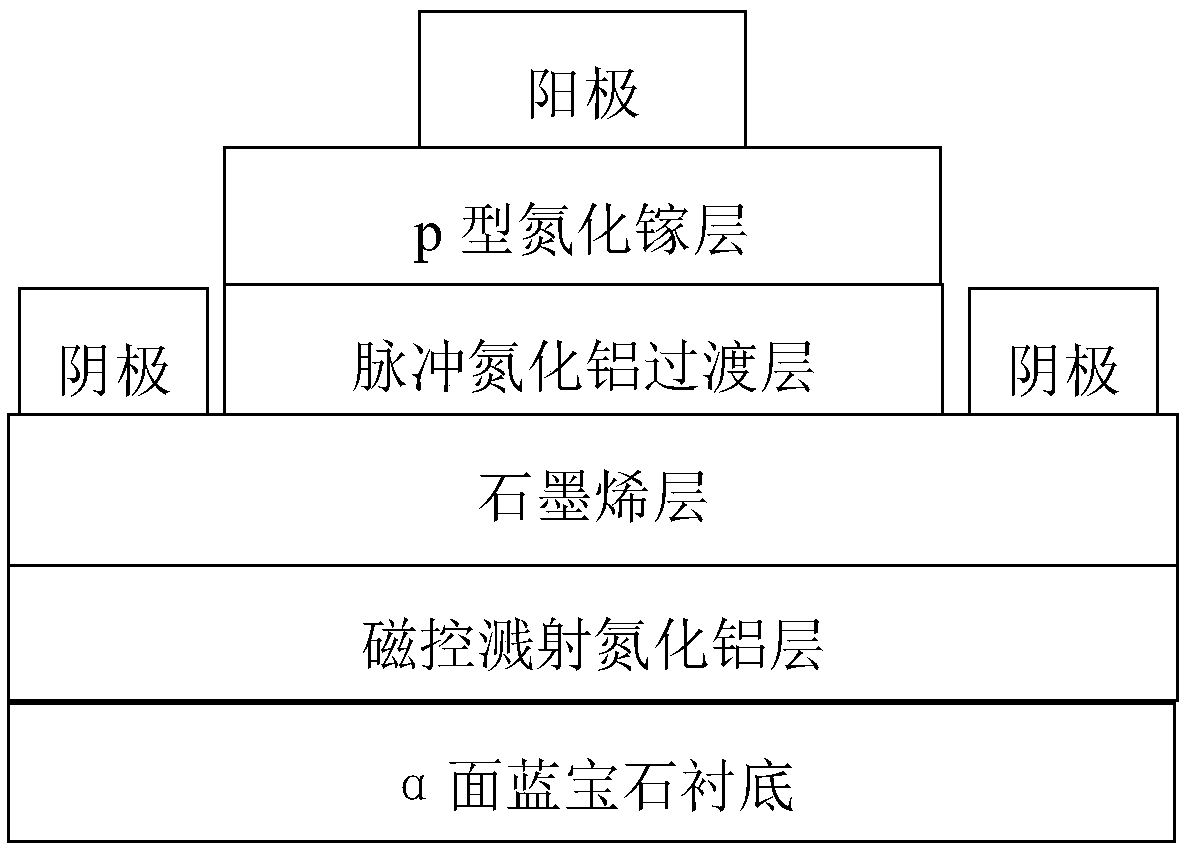

[0026] Example 1: Fabrication of a photodetector with a pulsed aluminum nitride transition layer thickness of 10 nm.

[0027] Step 1. Magnetron sputtering aluminum nitride film on α-plane sapphire substrate.

[0028] (1a) Place the α-face sapphire substrate in a magnetron sputtering system, the reaction chamber pressure is 1Pa, and nitrogen and argon are introduced into the system for 5 minutes;

[0029] (1b) Using aluminum with a purity of 99.999% as the target material, an aluminum nitride film with a thickness of 20nm is sputtered on the sapphire substrate by radio frequency magnetron sputtering to relieve the gap between the substrate and gallium nitride due to the crystal lattice Mismatch induced stress, resulting in sputtered AlN sapphire substrates.

[0030] Step 2. Transfer graphene onto magnetron sputtered aluminum nitride film.

[0031] (2a) adopt chemical vapor deposition method, grow the graphene layer of 0.34nm on copper substrate;

[0032] (2b) Place monolayer...

Embodiment 2

[0050] Example 2: Fabrication of a photodetector with a pulsed aluminum nitride transition layer thickness of 25 nm.

[0051] Step 1, magnetron sputtering aluminum nitride film on the α-plane sapphire substrate.

[0052] First place the α-plane sapphire substrate in the magnetron sputtering system, the pressure of the reaction chamber is 1Pa, and nitrogen and argon are introduced for 5 minutes, and then the aluminum with a purity of 99.999% is used as the target material, and the radio frequency magnetron sputtering is used. A 50nm aluminum nitride film was sputtered on the sapphire substrate to relieve the stress caused by lattice mismatch between the substrate and gallium nitride, and a sapphire substrate sputtered with aluminum nitride was obtained.

[0053] Step two, transfer the graphene onto the magnetron sputtered aluminum nitride film.

[0054] First adopt the chemical vapor deposition method to grow a 0.34nm graphene layer on the copper substrate; then place the sing...

Embodiment 3

[0065] Example 3: Fabrication of a photodetector with a pulsed aluminum nitride transition layer thickness of 50 nm.

[0066] Step A. Magnetron sputtering aluminum nitride thin film on α-plane sapphire substrate.

[0067] First, the α-face sapphire substrate was placed in a magnetron sputtering system, the reaction chamber pressure was 1 Pa, and nitrogen and argon were introduced for 5 minutes.

[0068] Then, using 99.999% pure aluminum as the target material, a 100nm thick AlN film was sputtered on the sapphire substrate by radio frequency magnetron sputtering to alleviate the lattice mismatch between the substrate and GaN. The resulting stress was obtained by sputtering AlN on a sapphire substrate.

[0069] Step B. Transfer graphene onto magnetron sputtered aluminum nitride film.

[0070] First, a graphene layer with a thickness of 0.34 nm is grown on a copper substrate by chemical vapor deposition;

[0071] Then, place the monolayer graphene in 64g / L (NH 4 ) 2 S 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com