Method for testing value of bonded prestress released after pre-reinforcement of existing structure

A technology of bonding prestressed and existing structures, applied in the direction of measuring force, measuring devices, instruments, etc., can solve problems such as waste of resources, inaccurate test results, and damage to prestressed tendons, so as to reduce excessive strength loss and avoid The effect that the measured data is too small and the measured data is accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

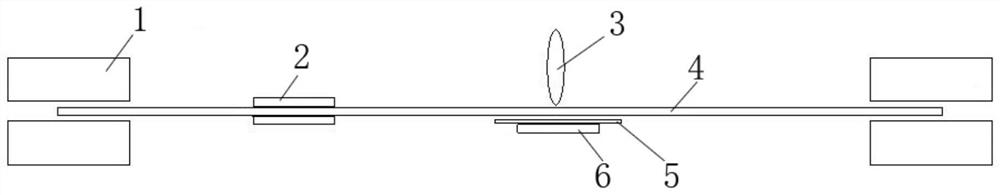

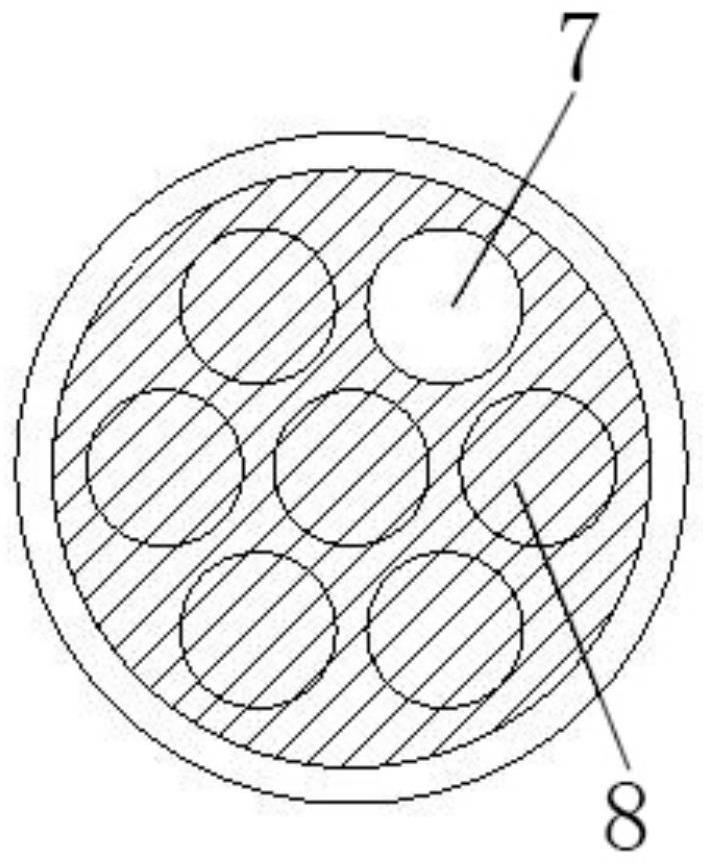

[0041] This embodiment provides the bonded prestress value test method released after the pre-reinforcement of the existing structure, refer to Figure 1 to Figure 2 , the existing structure includes a concrete structure 1 and bonded prestressed tendons 4, and the bonded prestressed tendons 4 and the concrete structure 1 are bonded together.

[0042] Specifically, the bonded prestressed tendons 4 are first placed in the reserved channels of the concrete structure 1, and after being tensioned and anchored, they are bonded with the surrounding concrete through grouting, so that the adhesive The prestressed tendons 4 are closely combined with the surrounding concrete, which improves the strength of the concrete structure 1; the concrete structure 1 is provided with a plurality of bonded prestressed tendons 4, and the bonded prestressed tendons 4 are all placed in the reserved tunnel, and after being tensioned and anchored, they are integrated with the surrounding concrete through...

Embodiment 2

[0053] This embodiment provides a method for measuring the stress value of bonded prestressed tendons released after the pre-reinforcement of the existing structure. Figure 1 to Figure 2 , the measurement method includes the steps of:

[0054] S1: chiseling the concrete structure in the 4 measuring point area with bonded prestressed tendons, and removing the structure so that the length of the exposed bonded prestressed tendons is greater than or equal to 30 cm;

[0055] S2: Grind the bonded prestressed tendons at the end of the bonded prestressed tendons 4 until the flat and smooth surface of the steel strand is exposed, and the upper and lower surfaces of the steel strand are along the prestressing direction on the symmetrical sides pasting two pieces of the first strain gauge 2;

[0056] S3: setting a cutting device at 10-20 cm of the first strain gauge;

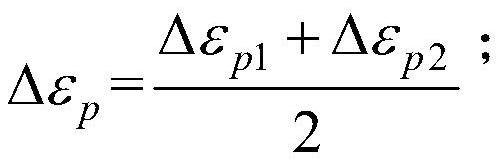

[0057] S4: Grinding the bonded prestressed tendons 4 at the position of the bonded prestressed tendons 4 on the oppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com