A kind of ultra-low-carbon high-strength high-plasticity martensitic steel and preparation method thereof

A martensitic steel, high-strength technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of steel strength limitation, welding performance and easy processing performance hazards, etc., to improve strength and plasticity, wide application range, The effect of good weldability

Active Publication Date: 2022-06-10

NORTHEASTERN UNIV LIAONING

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the field of high-strength steel preparation, the effect of the strengthening method on the material is decisive. The strengthening method of traditional high-strength steel mainly relies on solid solution strengthening of carbon and precipitation strengthening of alloy carbides. The strength of steel has a linear relationship with the content of carbon. When When the strength reaches a certain level, the carbon content also increases, which has great harm to the welding performance and easy processing performance. In the acceptable range of welding ability, the strength of steel is greatly limited.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

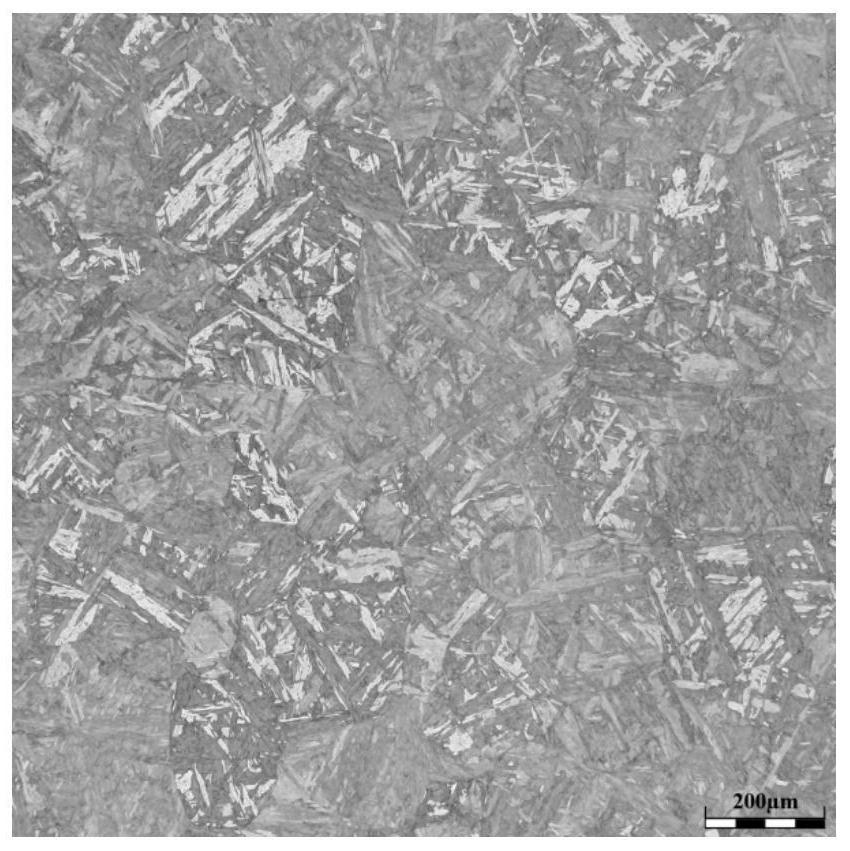

Embodiment 1

[0050] The cooling is air cooling.

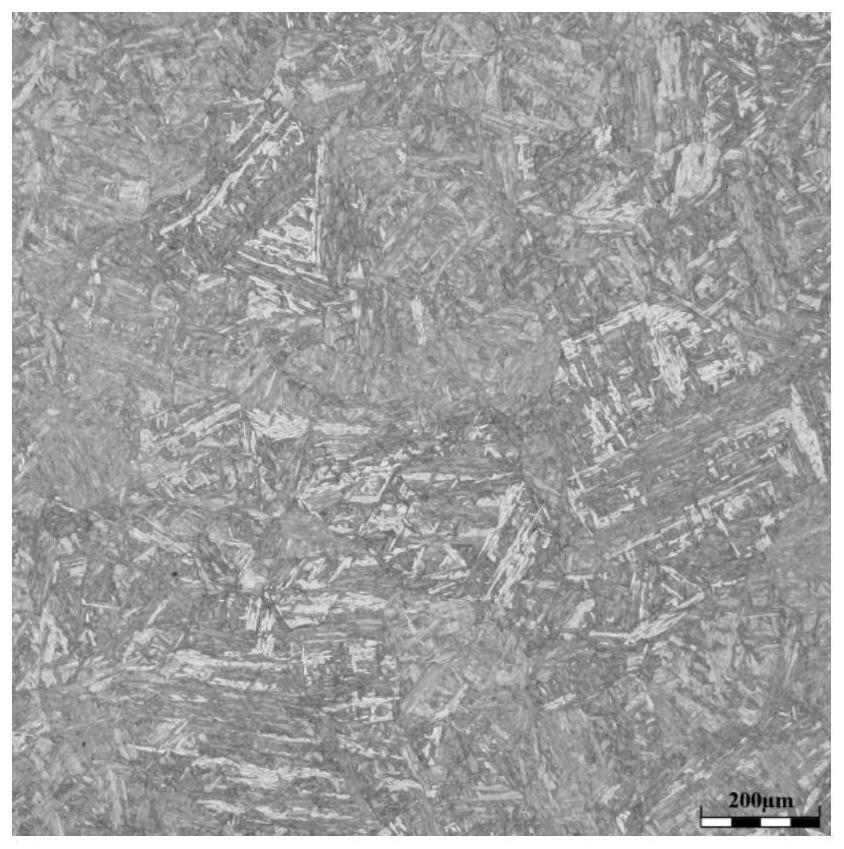

Embodiment 2

[0064] Step 4: The forged steel billet is heated from normal temperature to 1050°C at a rate of 210°C / h, maintained for 1h, and then quenched

[0066] The cooling is air cooling.

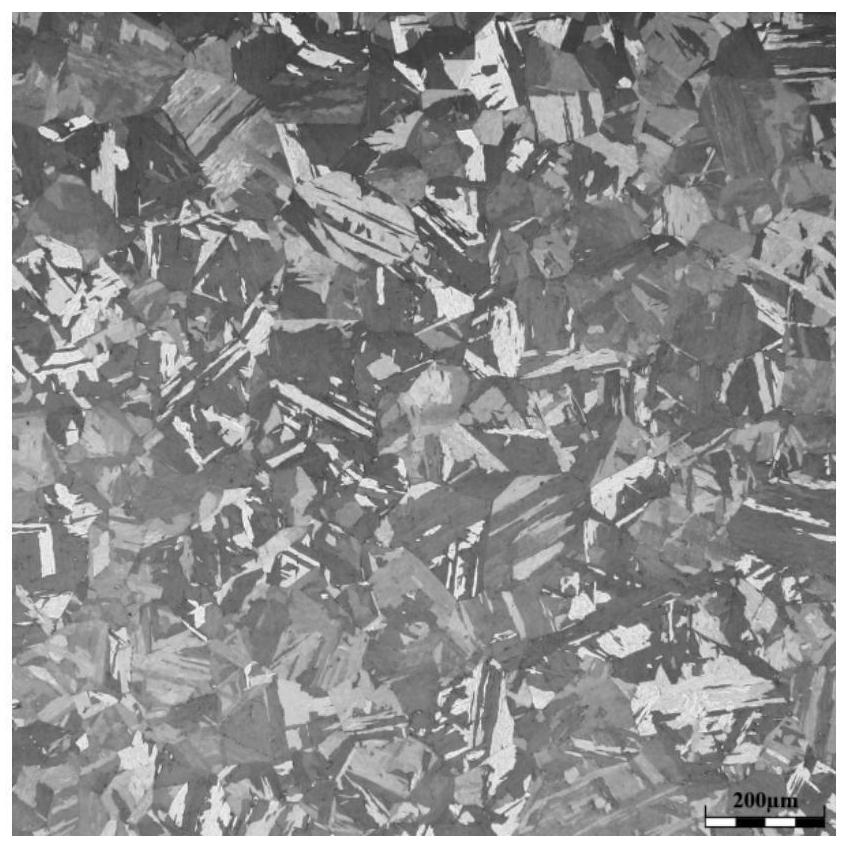

Embodiment 3

[0080] Step 4: The forged billet is heated from room temperature to 1050°C at a rate of 200°C / h, kept for 1 hour, and then quenched

[0082] The cooling is air cooling.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Login to View More

Abstract

An ultra-low-carbon, high-strength, high-plasticity martensitic steel and a preparation method thereof, belonging to the field of steel preparation, the mass percentage of the chemical composition of the martensitic steel is: C: 0.01-0.05%, Si: 0.2-0.5%, Mn: 0.5~0.8%, Cr: 0.8~1.2%, Cu: 2.0~4.0%, Ni: 10.0~11.0%, V: 0.05~0.15%, Mo: 0.5~0.9%, Al: 0.2~0.5%, P: ≤ 0.02%, S: ≤0.02%, the balance is Fe. Adding Cu, Ni, Al and Mn elements to the alloy of the present invention can precipitate rich Cu and Ni during the aging heat treatment process. 3 Al(Mn) phase, so as to realize the high strength of the alloy and excellent welding performance; the martensitic steel of the present invention does not need rolling, cryogenic treatment, simple heat treatment process, high production efficiency, and easy realization.

Description

A kind of ultra-low carbon high strength high plastic martensitic steel and preparation method thereof technical field The invention belongs to steel preparation field, particularly a kind of ultra-low carbon high strength high plastic martensitic steel and preparation method thereof Law. Background technique With the continuous development of modern science and technology, the application field of high-strength steel is continuously developed, and people's pursuit of steel performance Demand is also increasing. In the field of high-strength steel preparation, the effect of strengthening methods on materials is decisive. The chemical method mainly depends on the solid solution strengthening of carbon and the precipitation strengthening of alloy carbides, and the strength of steel is linearly related to the content of carbon. When the strength reaches a certain level, the carbon content also increases, which has a great danger to the welding performance and ease of p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/06C22C38/42C22C38/44C22C38/46C21D1/18C21D1/78C21D6/00C21D9/00C22C33/06

CPCC22C38/02C22C38/04C22C38/42C22C38/46C22C38/44C22C38/06C22C33/06C21D1/18C21D1/78C21D9/0081C21D9/0075C21D6/004C21D6/005C21D6/008C21D2211/008

Inventor 董艳伍彭飞田家龙姜周华

Owner NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com