Phosphor-rich graphene flame-retardant agent and preparation method thereof

A technology of flame retardant and graphene, which is applied in coatings, fireproof coatings, polyurea/polyurethane coatings, etc., can solve the problems of limited improvement of polymer flame retardancy and cannot be independently used as a flame retardant, and achieves an improvement Barrier effect, improvement of overall strength and compactness, improvement of flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

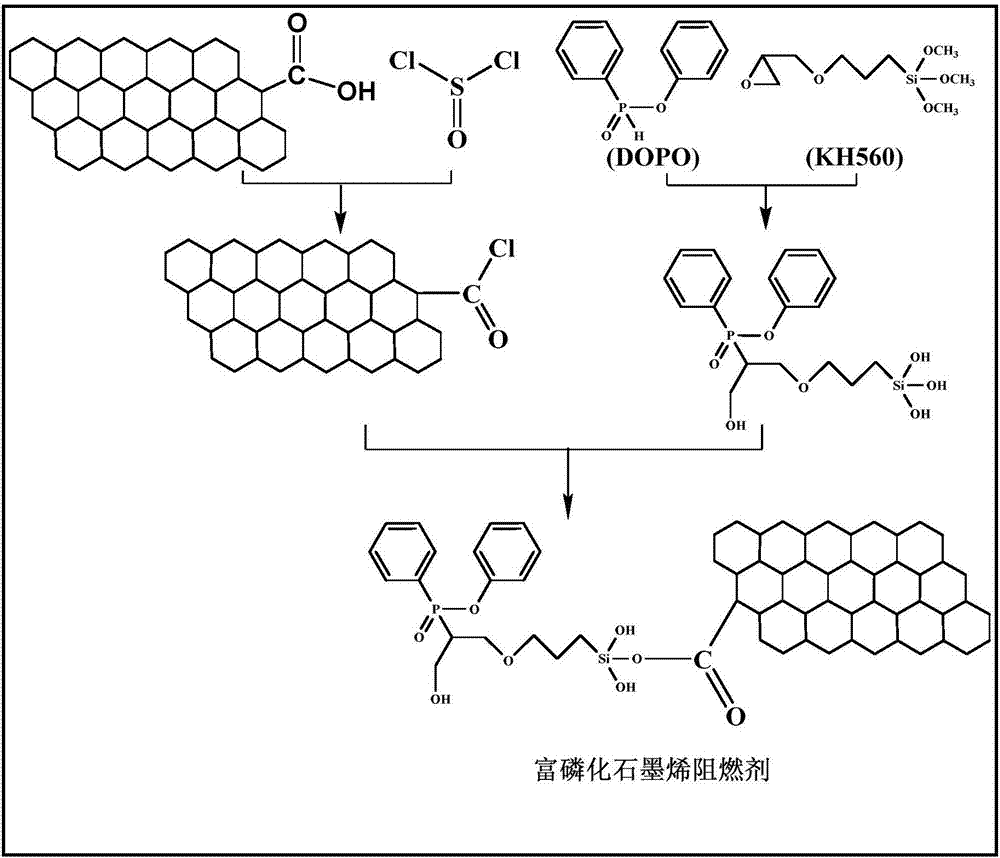

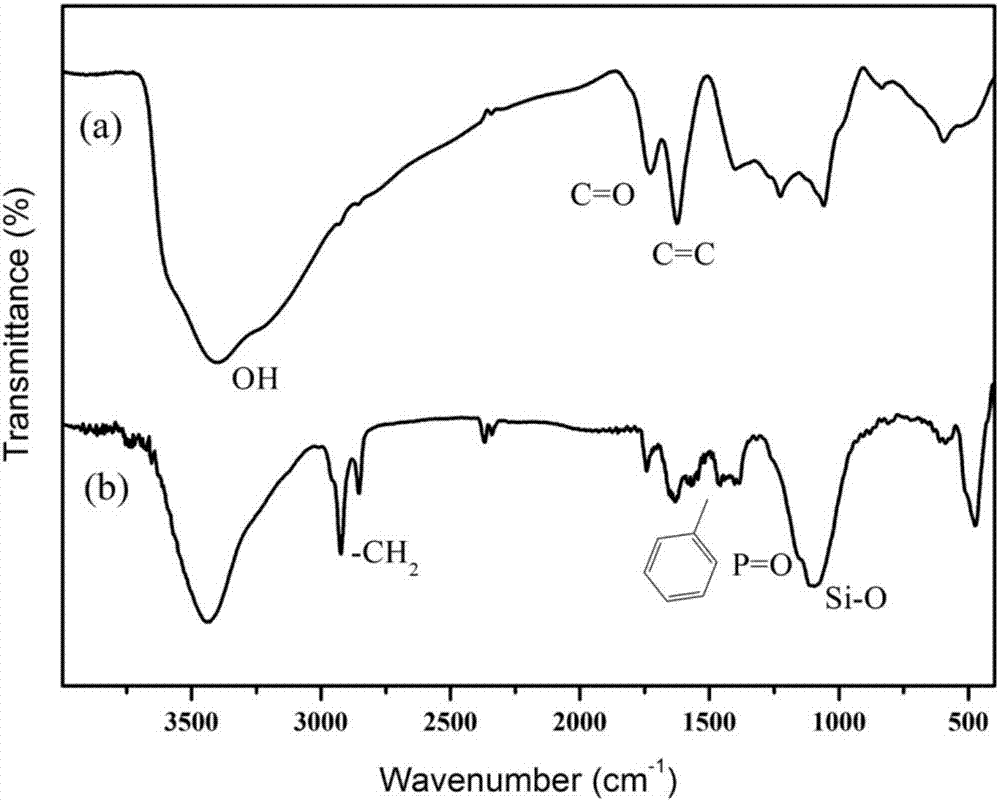

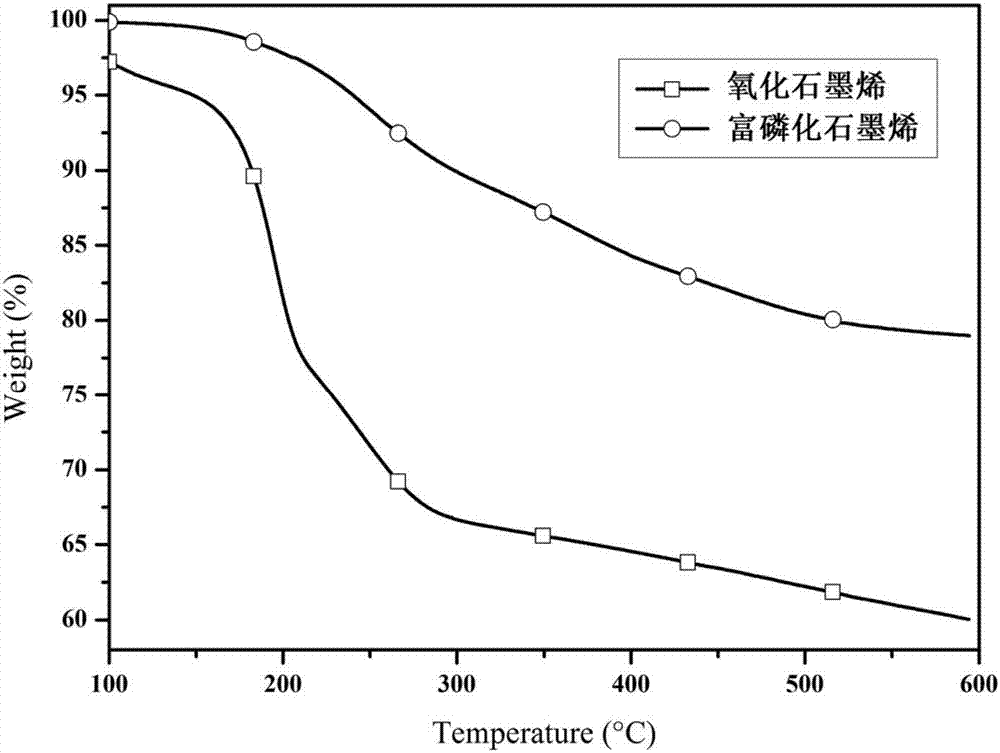

[0031] Embodiment 1 Preparation of rich phosphorized graphene flame retardant of the present invention

[0032]Under a nitrogen atmosphere, 4.28g CEPPA and 4.42kg KH560 (molar ratio 1:1) were heated, melted and mixed uniformly, and stirred and reacted at 120°C for 6h to obtain a CEPPA-linked silane coupling agent intermediate compound; 0.9ml deionized Add water (10wt%) to the intermediate compound, stir and hydrolyze at room temperature for 12 hours to remove excess water; disperse 1g of graphene oxide in 100ml of thionyl chloride for surface activation to obtain graphene acid chloride (GO-COCl), drop a few drops DMF was used as a catalyst, and after 24 hours of reaction, the excess thionyl chloride was removed by rotary evaporation, and the powder was dispersed in tetrahydrofuran to obtain a GO-COCl dispersion. The dried intermediate hydrolyzate was completely dissolved in tetrahydrofuran and added dropwise to GO-COCl The dispersion liquid was heated, stirred and refluxed for...

Embodiment 2

[0034] Embodiment 2 Preparation of rich phosphorized graphene flame retardant of the present invention

[0035] Under the atmosphere of helium, 4.32g DOPO and 4.73kg KH550 (molar ratio 1:1) were heated, melted and mixed uniformly, and stirred and reacted at 160°C for 8h to obtain the intermediate compound of DOPO-linked silane coupling agent; Ionized water (5wt%) was added to the intermediate compound, stirred and hydrolyzed at room temperature for 24h to remove excess water; 1.5g graphene oxide was dispersed in 200ml thionyl chloride for surface activation to obtain graphene acid chloride (GO-COCl), dropwise A few drops of dimethylacetamide was used as a catalyst, and after 12 hours of reaction, the excess thionyl chloride was removed by rotary evaporation, and the powder was dispersed in dichloromethane to obtain a GO-COCl dispersion, and the dried intermediate hydrolyzate was completely dissolved in di Add the GO-COCl dispersion dropwise into the methyl chloride, heat, stir...

Embodiment 3

[0040] Embodiment 3 Preparation of rich phosphorized graphene flame retardant of the present invention

[0041] Under a nitrogen atmosphere, 4.28g of CEPPA and 3.94kg of aminopropyltrimethoxysilane (molar ratio 1:1.1) were heated, melted and mixed uniformly, and stirred and reacted at 120°C for 6 hours to obtain a CEPPA-linked silane coupling agent intermediate compound; 0.6ml of deionized water (7wt%) was added to the intermediate compound, stirred and hydrolyzed at room temperature for 8h to remove excess water; 1.5g of graphene oxide was dispersed in 200ml of thionyl chloride for surface activation to obtain graphene acyl chloride (GO-COCl ), drop a few drops of lutidine as a catalyst, and remove excess thionyl chloride by rotary evaporation after 24 hours of reaction, and disperse the powder in ethyl acetate to obtain a GO-COCl dispersion, and completely dry the intermediate hydrolyzate Dissolve in ethyl acetate and add GO-COCl dispersion drop by drop, heat, stir and reflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com