Multi-heat pipe cooling module and manufacturing method thereof

A technology of a heat dissipation module and a manufacturing method, which is applied to lighting and heating equipment, cooling/heating devices for lighting devices, electrical components, etc., can solve problems such as deformation, bending, difficulty in piercing heat pipes, and difficulty in piercing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to further understand the characteristics and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. However, the accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention. .

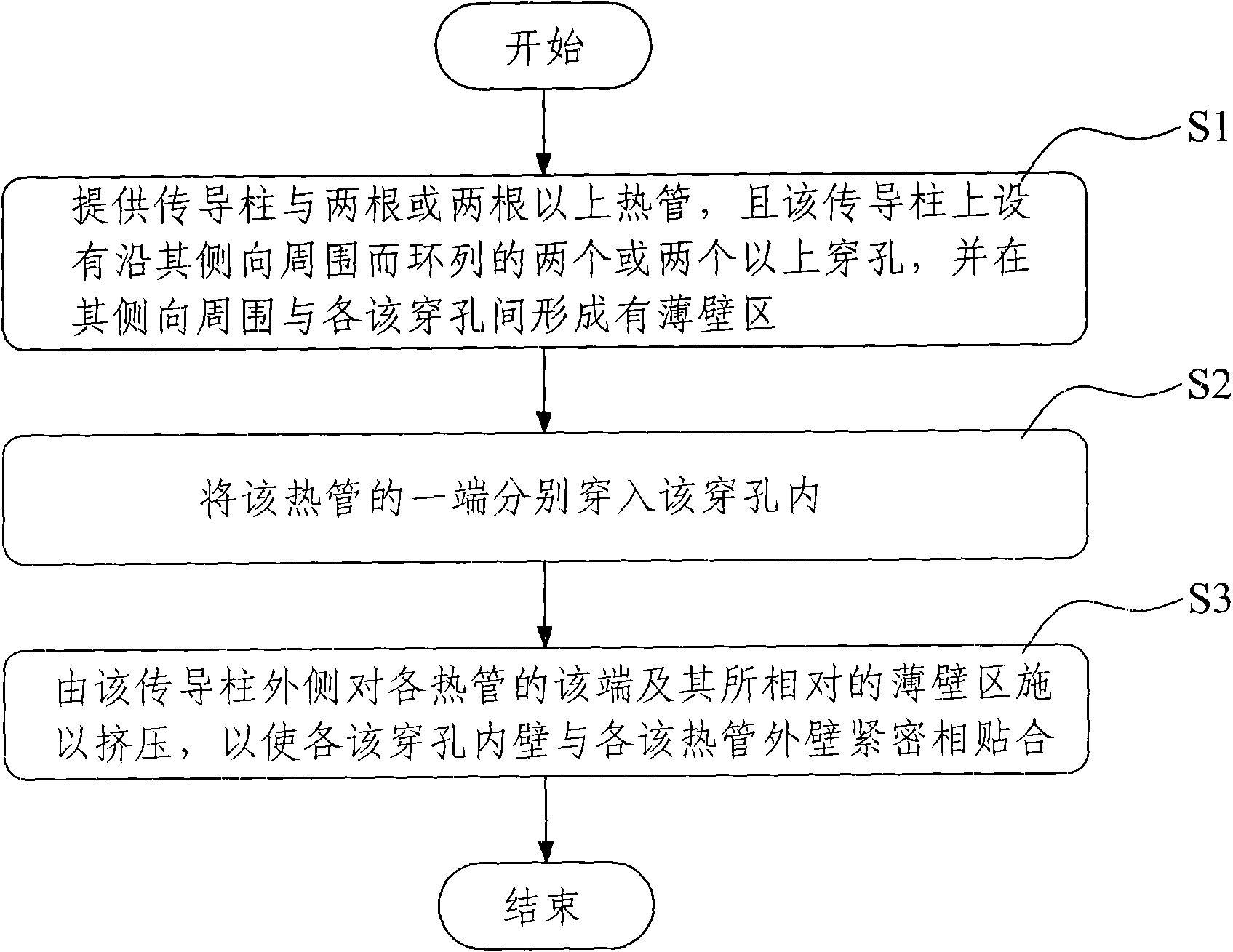

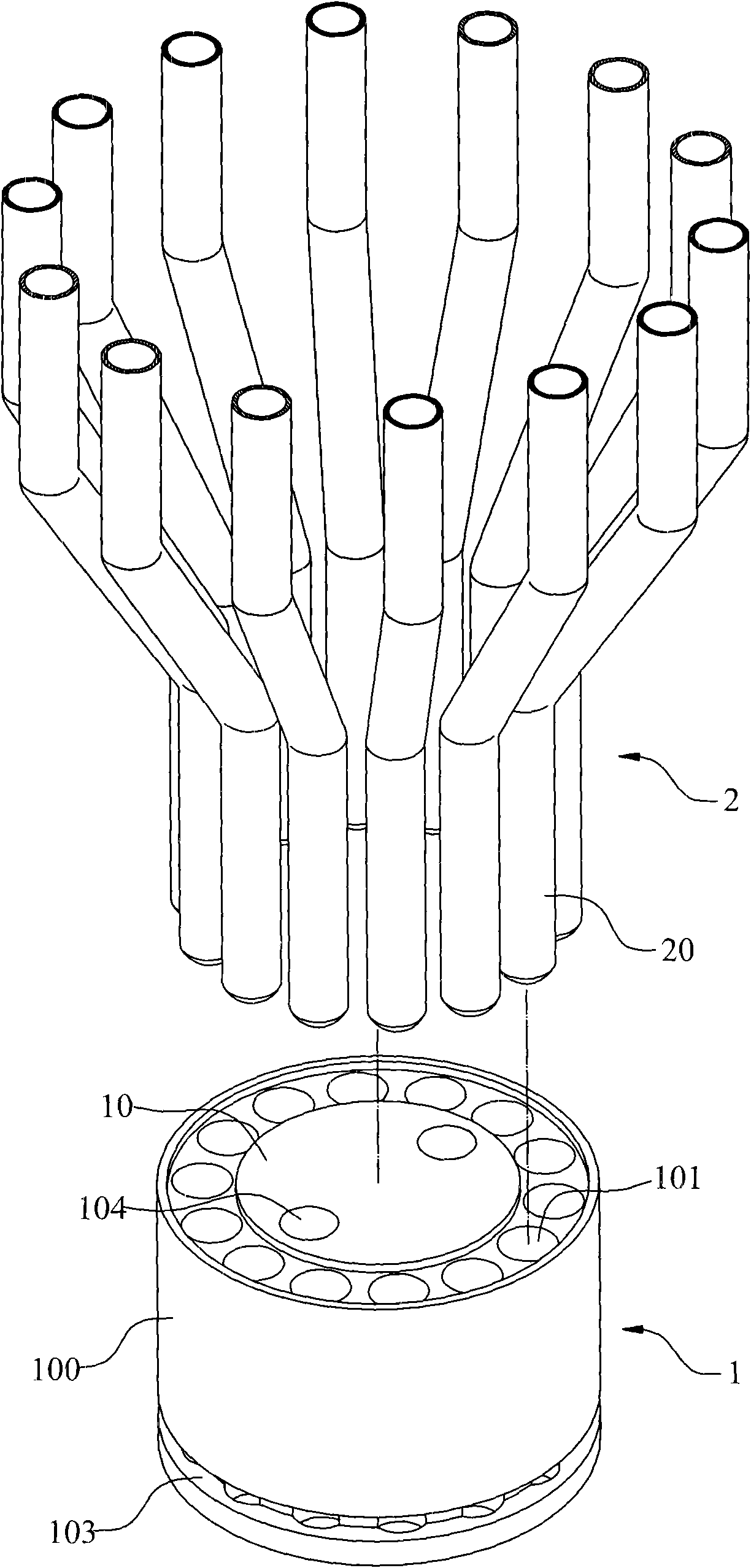

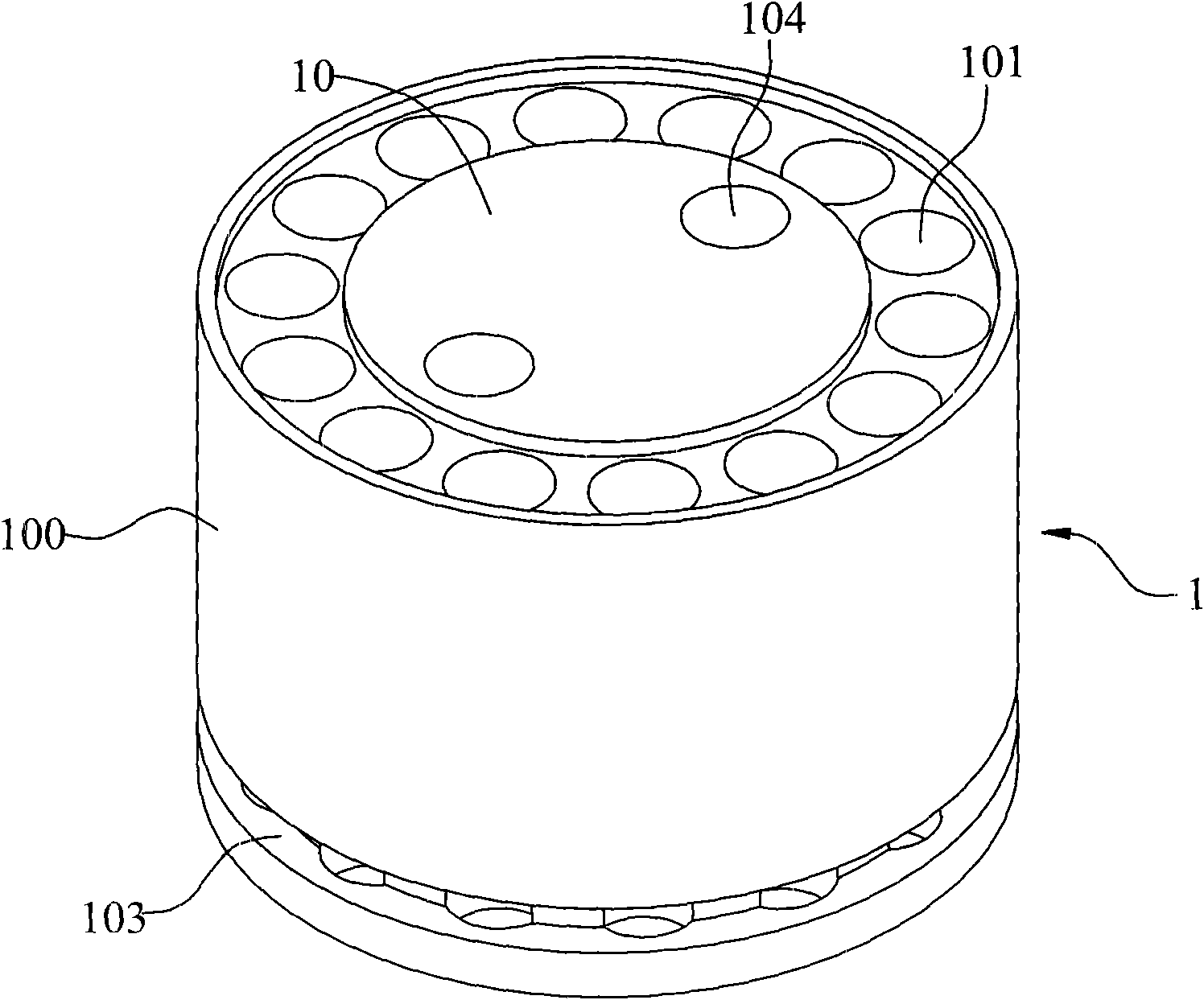

[0037] The invention provides a multi-heat pipe cooling module and a manufacturing method thereof. see figure 1 Step S1, providing a conduction column and two or more heat pipes, and the conduction column is provided with two or more perforations along its lateral circumference, and each of the perforations is arranged around its lateral circumference A thin-walled area is formed between; and cooperate with figure 2 As shown: firstly, a heat conduction base 1 and two or more heat pipes 2 are provided, and the heat conduction base 1 has the following structural features:

[0038] Such as image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com