Paper operation monitoring component of laminating machine

A technology of operation monitoring and laminating machine, which is applied to the general parts of printing machinery, printing machines, printing, etc. It can solve the problems of lamination deviation, paper wrinkling, paper jamming, etc., so as to improve product quality and avoid lamination Air bubbles and the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

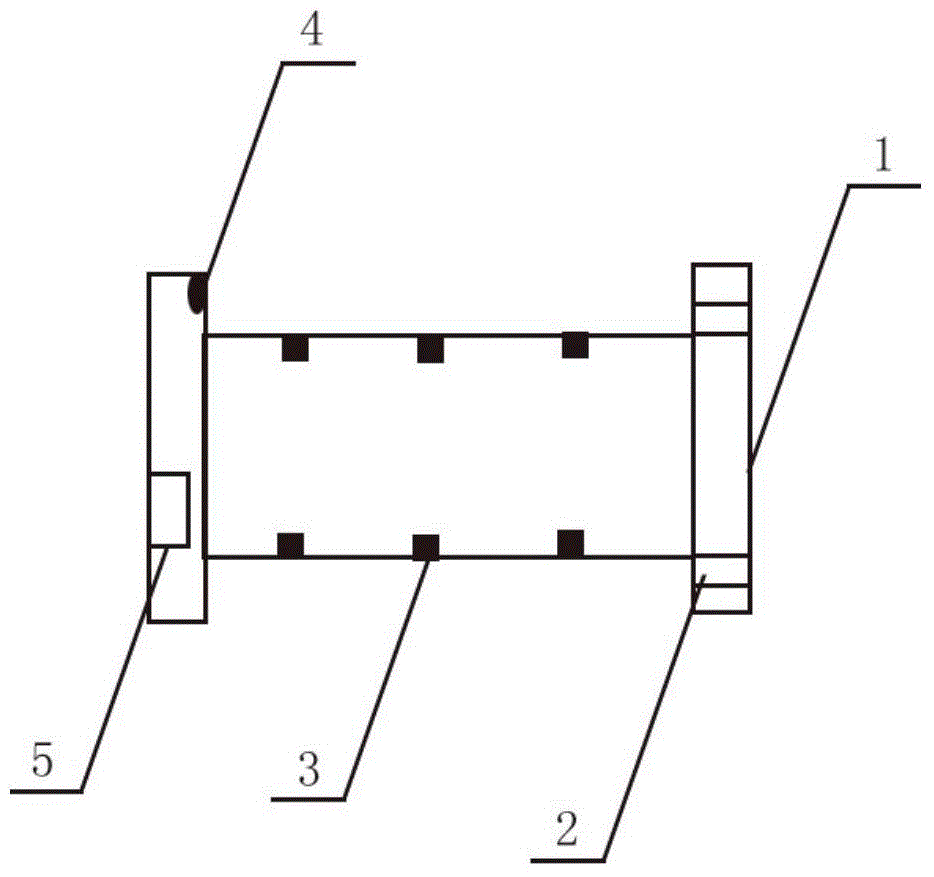

[0012] Embodiment: as shown in the accompanying drawing. The paper running monitoring component of the laminating machine includes a laminating body (1), and marking devices (2) are set on both sides of the paper feeding device of the body (1). When the paper is sucked into the front part of the body, marks Corresponding to the small marks, an induction monitoring device (3) is installed on the translational part of the body to monitor the flatness and running status of the paper.

[0013] The paper running monitoring component of the laminating machine is equipped with a prompting device (4), which promptly reminds the operator to adjust the operation mode when the paper position is shifted, wrinkled, damaged, etc.

[0014] The paper running monitoring component of the laminating machine and the marking device (2) are made of new materials, which do not affect the integrity of the paper, and are marked on the discarded part of the edge of the paper.

[0015] The paper runnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com