Forming machine for gypsum board production line

A production line and gypsum board technology, applied in the field of forming machines of gypsum board production line, to achieve the effects of saving manpower, wide application range and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

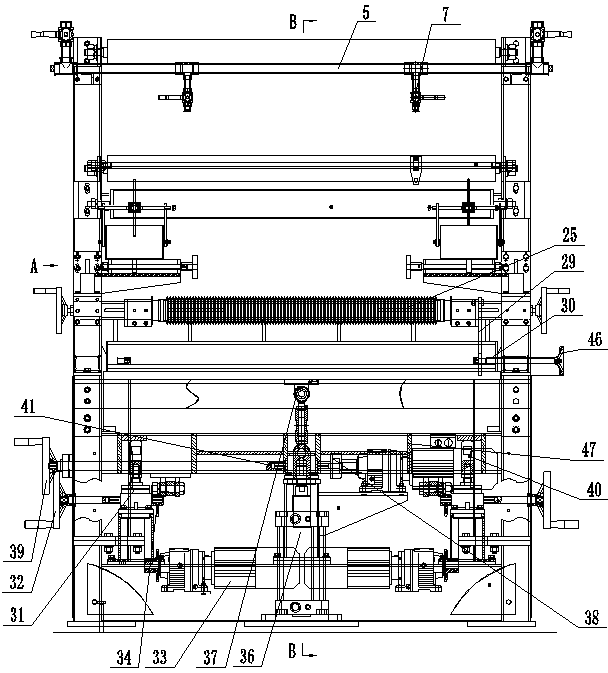

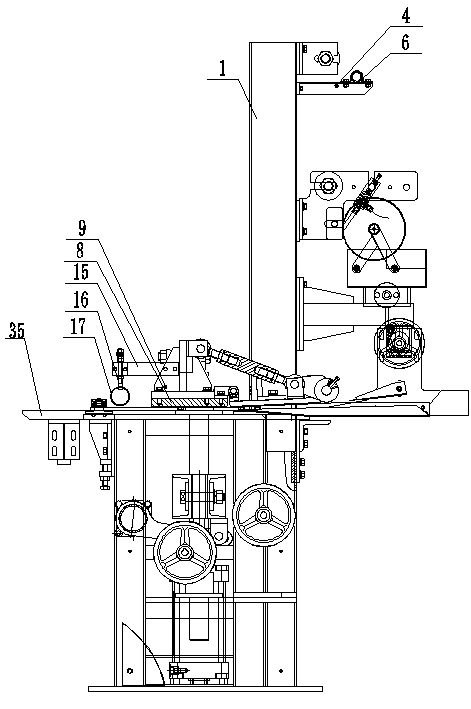

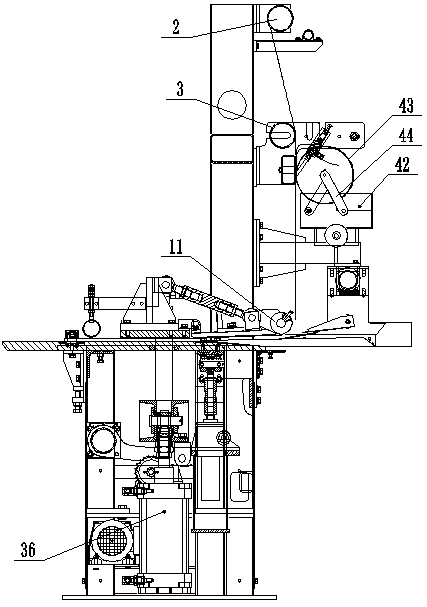

[0034] The forming machine used in the gypsum board production line of the present invention has a structure comprising a frame 1, on which a sizing device, a gluing device, an upper forming device and a lower forming device are sequentially arranged from top to bottom, and the sizing device An upper paper guide roller 2 and a middle paper guide roller 3 are respectively installed above and below, and the upper paper guide roller 2 and the middle paper guide roller 3 are used to control the direction of the paper to ensure uniform sizing; the sizing device includes a pipe bracket 4, a pipe The bracket 4 is fixedly installed on the frame 1, the sizing hose 5 is installed on the pipe bracket 4, the sizing hose 5 is fixed on the pipe bracket 4 through the pipe clamp 6, and the ball valve 7 is installed on the sizing hose 5, the ball valve 7 is used to control the flow rate of the glue; the upper forming device includes an upper forming plate 8, an upper forming plate support 9, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com