Integrated wall surface installation structure

A technology for installing structures and decorative surfaces, applied in building construction, covering/lining, construction, etc., to achieve the effects of convenient installation, reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

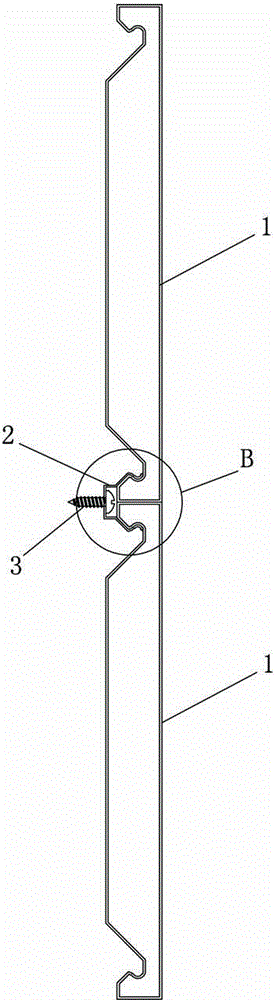

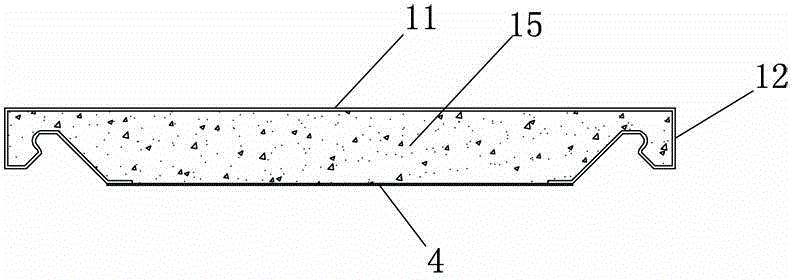

[0023] see Figure 1 to Figure 6 , the integrated wall installation structure in this embodiment includes a wall module 1 , clips 2 , screws 3 and a mounting plate 4 .

[0024] The clamp strip 2 in this embodiment is made of elastic material, and the specific material can be extruded from a profile or cold-bent from a steel strip.

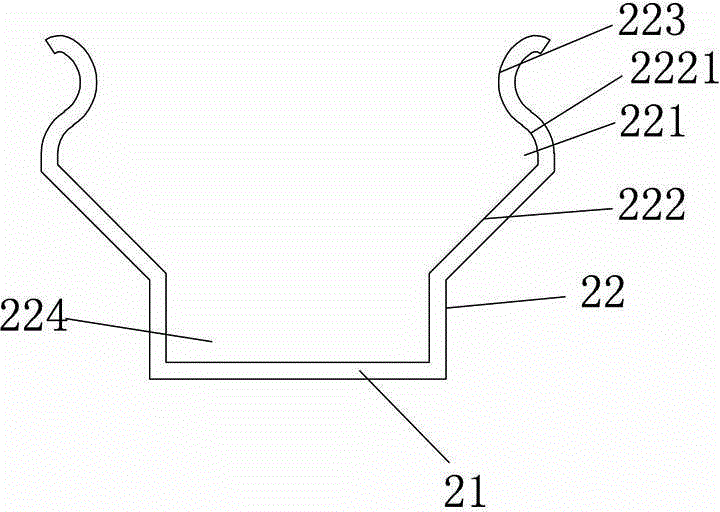

[0025] The wall module 1 in this embodiment has a square structure and has a decorative surface 11 and a side surface 12. The side surfaces 12 are all perpendicular to the decorative surface 11. One end of the side surface 12 is connected to the decorative surface 11 and the other end extends to the inside of the wall module 1. And form a bending edge 13, the bending edge 13 is provided with a buckle 131, and the buckle 131 is convex relative to its corresponding side 12; the clip 2 includes a bottom edge 21 and two symmetrically arranged on the bottom edge 21 is on the card edge 22 , and the card edge 22 has a fastening groove 221 matched with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com