Manufacturing method of inflating product pulling piece

The technology of an inflatable product and a production method is applied in the field of production of inflatable product pull tabs, which can solve the problems of large folded volume, limited force of plastic sheets, and increased weight of inflatable products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

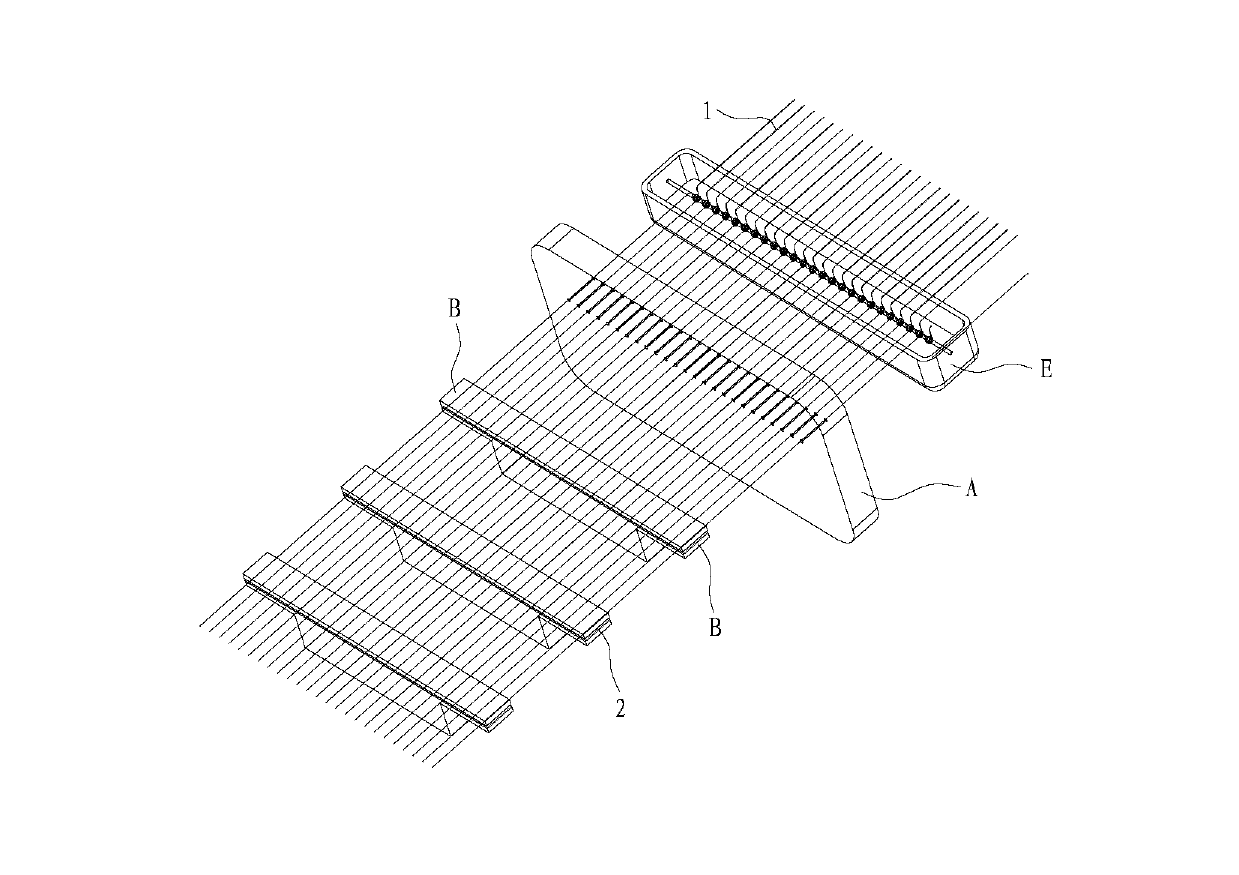

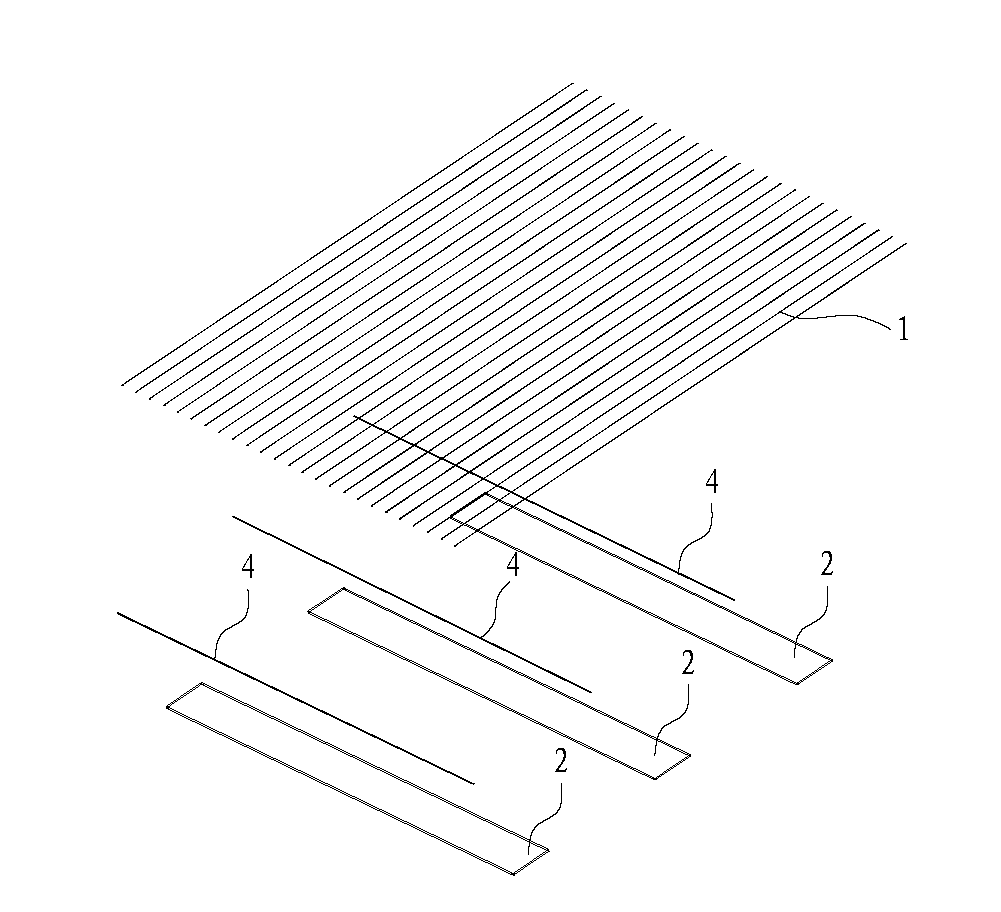

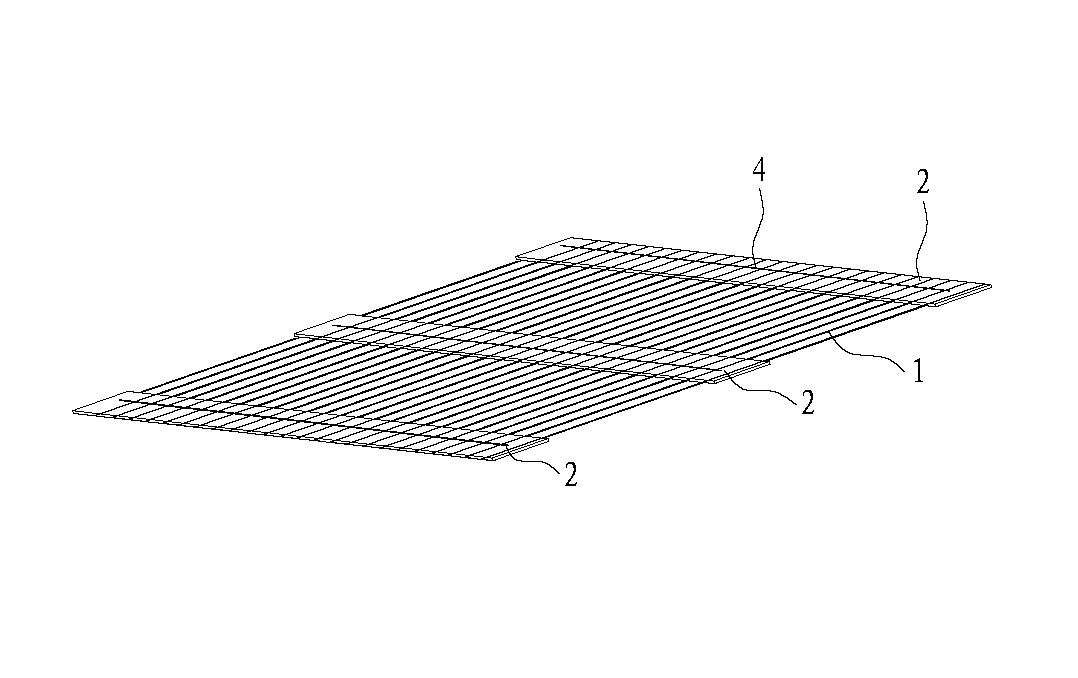

[0040] like figure 1 and cooperate Figure 2 to Figure 5 As shown, the present invention discloses a manufacturing method of an inflatable product pull tab, and its specific steps are:

[0041] Step 1, the plurality of thread bodies 1 provided by the yarn unwinding frame are continuously conveyed through the thread clamping tool A and are arranged in a uniform and parallel arrangement in a plane; this thread body is made of twisted yarn;

[0042] Step 2, a glue groove E is arranged in front of or behind the wire clamping tool A, and the plurality of wire bodies 1 are adhered with glue through the glue groove E; the glue groove E here is a glue groove or a glue groove, and Realize continuous gluing or intermittent gluing of line body 1;

[0043] Step 3. According to the moving direction of the wire body 1, a fixing device is further set behind the wire clamping tool A, and a plastic strip 2 whose length is adapted to the arrangement width of the plurality of wire bodies 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com