Slitting machine for machining aluminum foil packaging bag

A packaging bag and slitting machine technology, which is applied in the packaging field, can solve the problems of low efficiency of slitting and cutting packaging bags, and achieve the effect of ensuring continuity and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

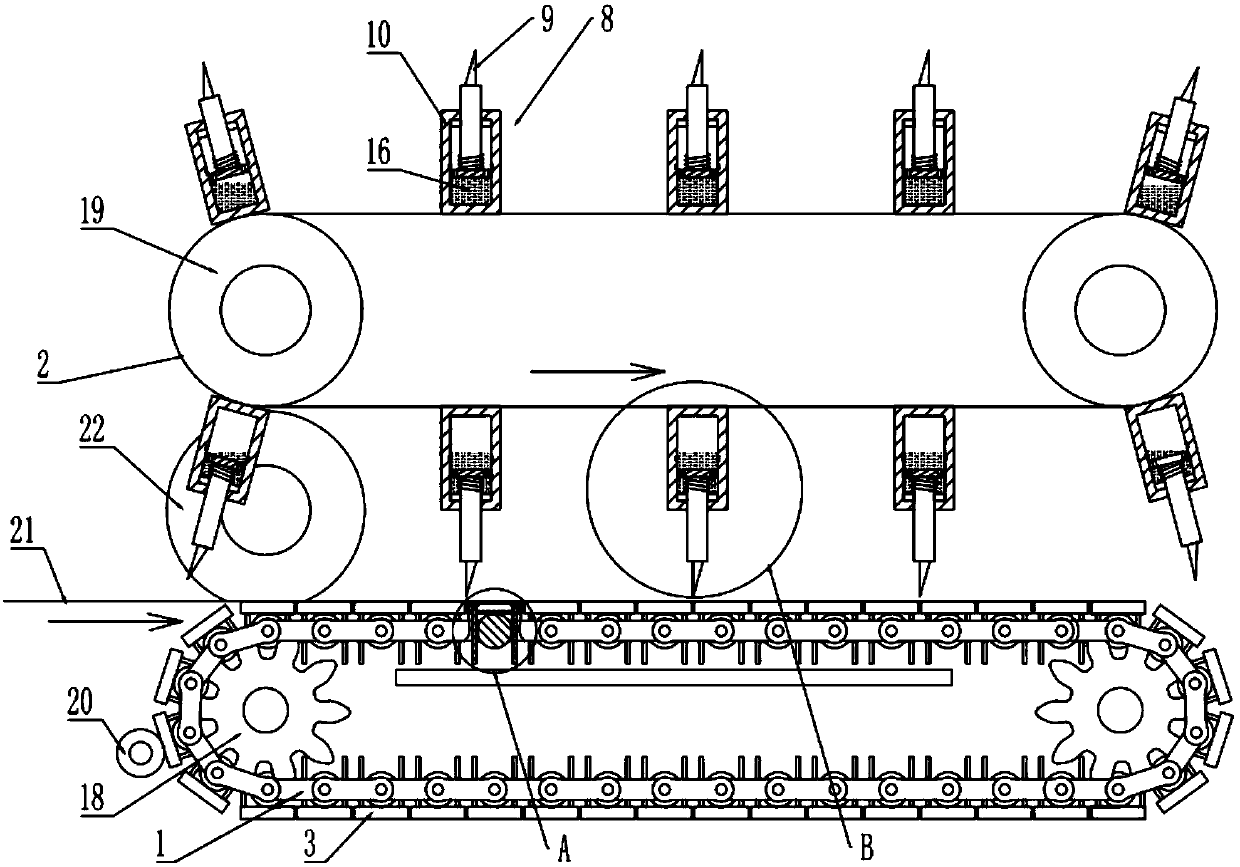

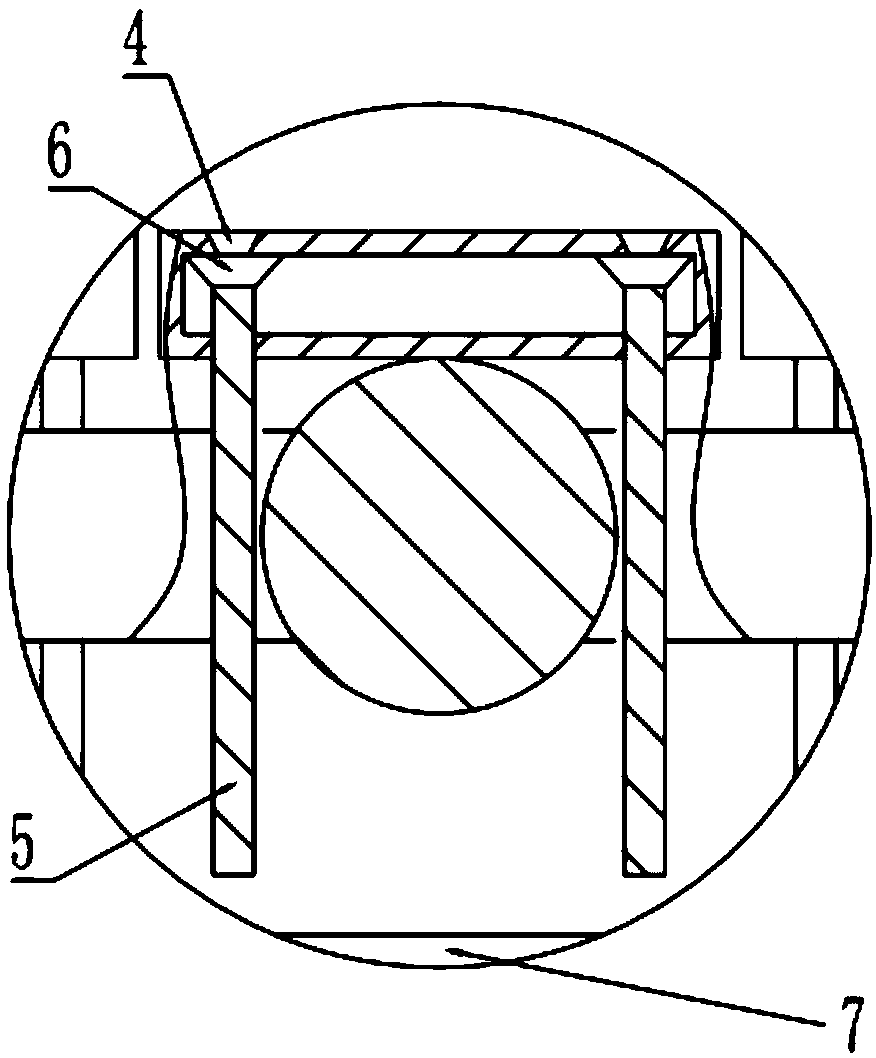

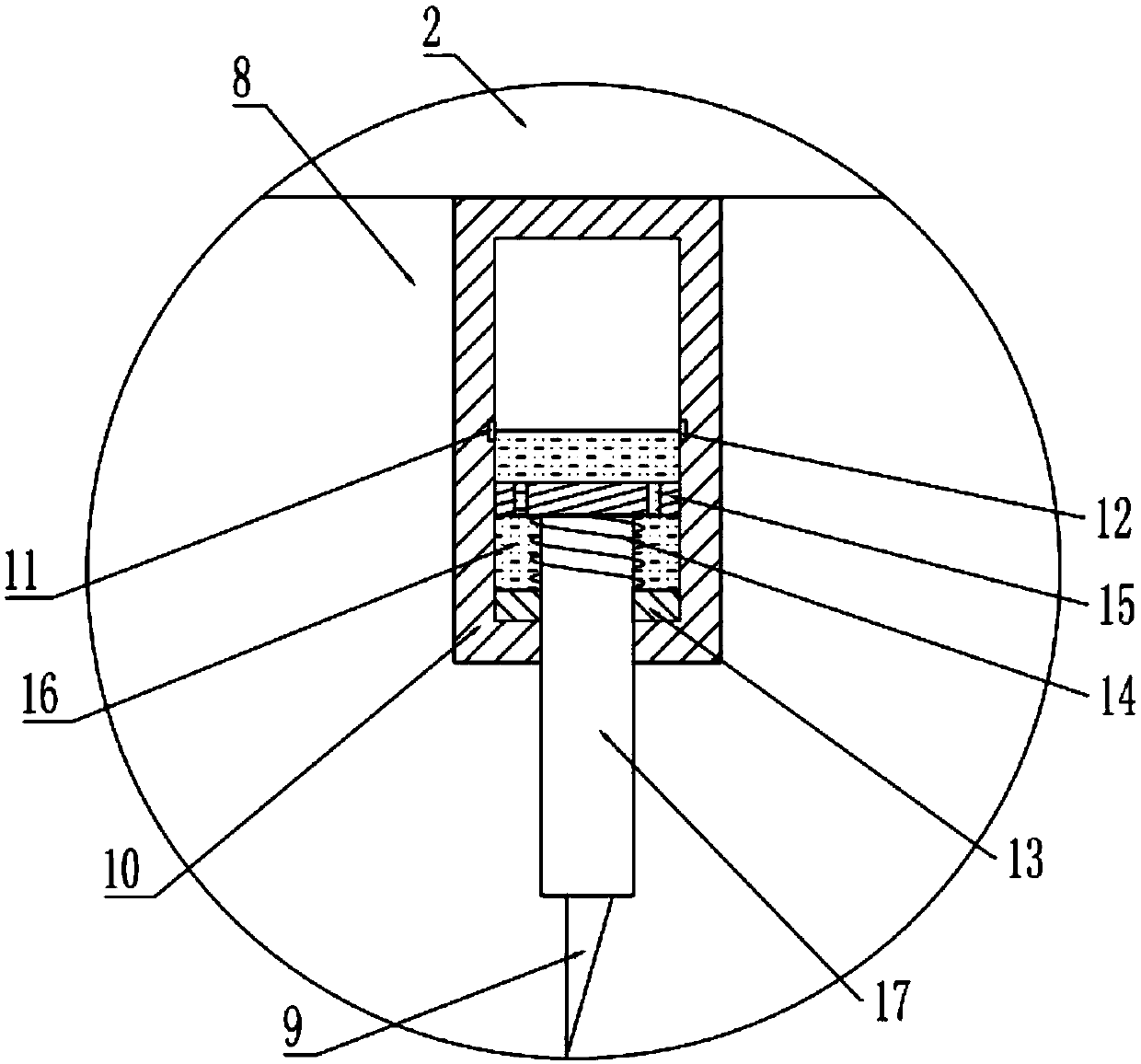

[0029] The reference signs in the drawings of the description include: iron plate conveying line 1, circular cutter moving line 2, iron plate 3, air suction hole 4, sliding rod 5, suction cup 6, permanent magnet plate 7, cutting unit 8, cutting knife 9 , cylinder block 10, conductive sheet 11, conductive sheet 2 12, electromagnet 13, spring 14, slider 15, electrolyte solution 16, connecting rod 17, sprocket 18, pulley 19, cleaning roller 20, packaging bag 21, gear Three 22.

[0030] The embodiment is basically as attached Figure 1 to Figure 3 Shown:

[0031] The slitting machine for aluminum foil packaging bag processing includes a packaging bag conveying line and an annular knife moving line 2, the packaging bag conveying line is an iron plate conveying line 1, the annular knife moving line 2 and the iron plate conveying line 1 have the same size and direction Line speed.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com