Instant cloth cover quality detection system

A detection system and quality technology, applied in textiles, textiles, papermaking, looms, etc., can solve problems such as weft yarn slipping and affecting the smoothness of the coating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

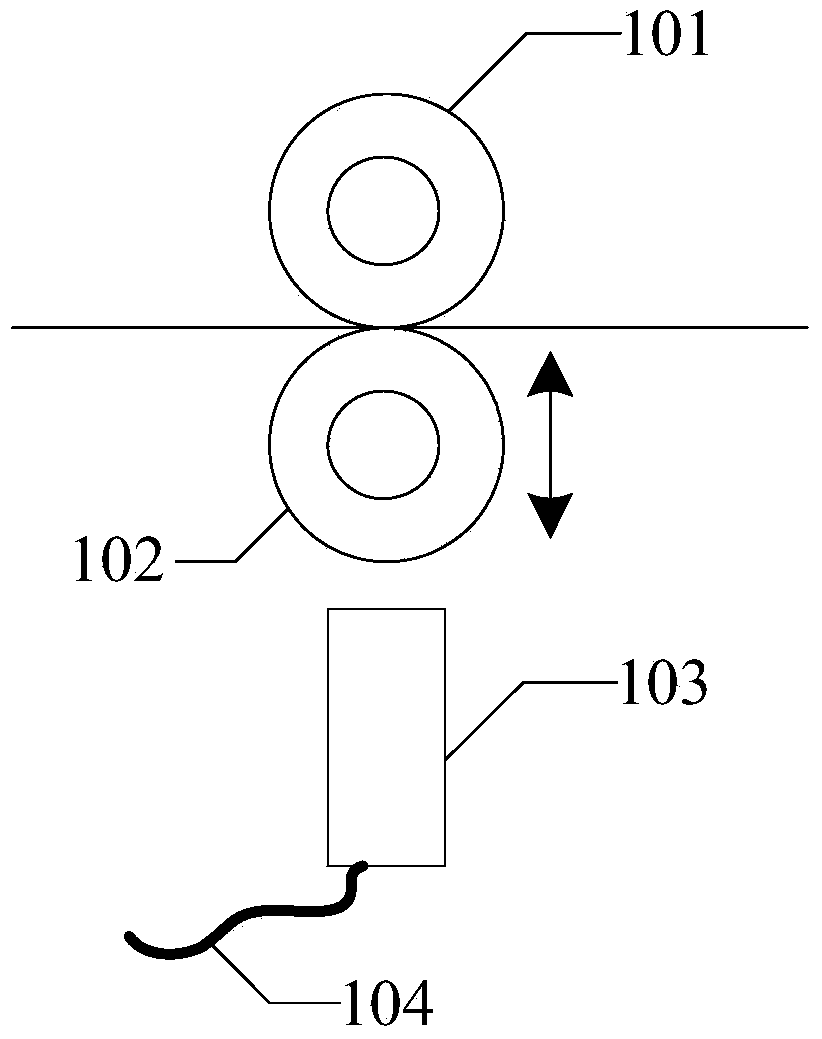

[0029] Embodiment 1 of the present application provides a real-time detection system for cloth surface quality, such as figure 1 as shown, figure 1 It is a schematic structural diagram of a real-time cloth quality detection system provided in Embodiment 1 of the present application. The detection system includes: a first bearing 101 , a second bearing 102 , a proximity switch 103 and a proximity switch wire 104 .

[0030] The rolling surfaces of the first bearing 101 and the second bearing 102 are contactable, and are used for guiding the weft yarn and fixing the longitudinal position of the weft yarn.

[0031] Wherein, the first bearing 101 is a fixed rotating bearing, and the second bearing 102 is a bearing that can slide perpendicular to the traveling direction of the weft yarn.

[0032] When the second bearing 102 slides away from the first bearing 101, it contacts with the sensing end of the proximity switch 103 to trigger the proximity switch 103. After the proximity s...

Embodiment 2

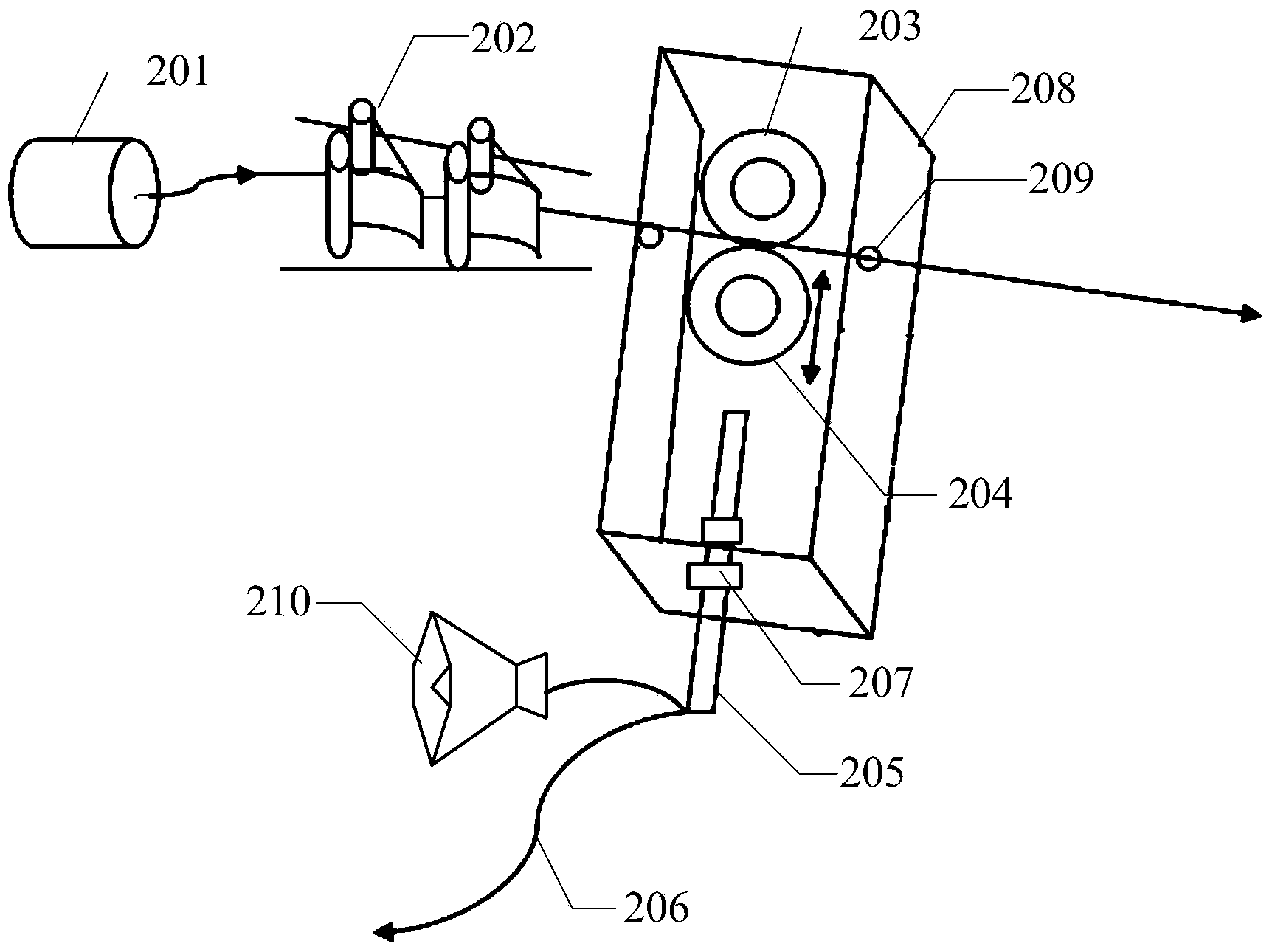

[0036] Embodiment 2 of the present application provides another kind of real-time detection system of cloth surface quality, such as figure 2 as shown, figure 2 It is a schematic structural diagram of a real-time cloth quality detection system provided in Embodiment 2 of the present application. The detection system includes: yarn reel 201, weft tensioner 202, first bearing 203, second bearing 204, proximity switch 205, proximity switch wire 206, adjustment nut 207, base 208, magnetic eye 209 and alarm device 210.

[0037] The yarn roll 201 is used for providing weft yarn.

[0038] The weft yarn tensioner 202 is used to apply tension to the weft yarn leading to the shed of the loom, and to eliminate the air loop generated when the weft yarn is unwound from the yarn roll.

[0039] Wherein, the weft yarn tensioner can be composed of a tension sheet and a tension sheet fixing device, and of course it can also be other devices capable of providing a certain tension for the wef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com