Touch panel

A technology of touch panel and cover plate, applied in the direction of electronic equipment, lamination, application, etc., to achieve the effect of reducing damage, low production cost, and reducing erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

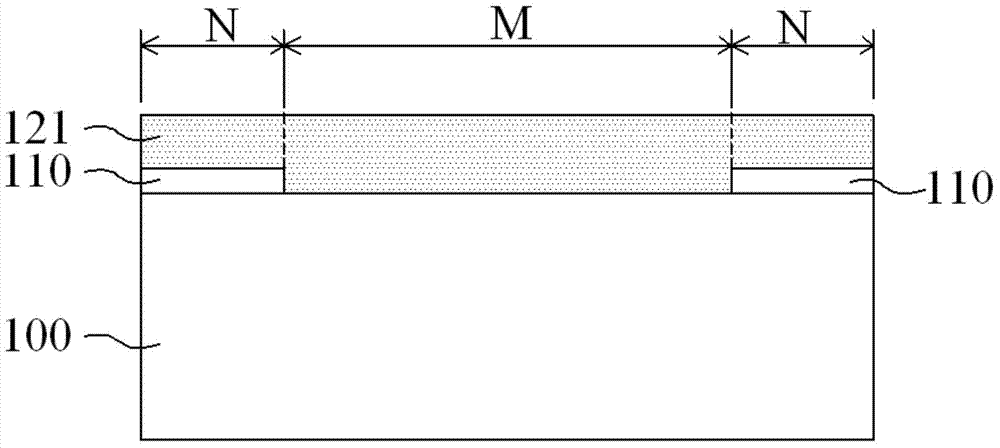

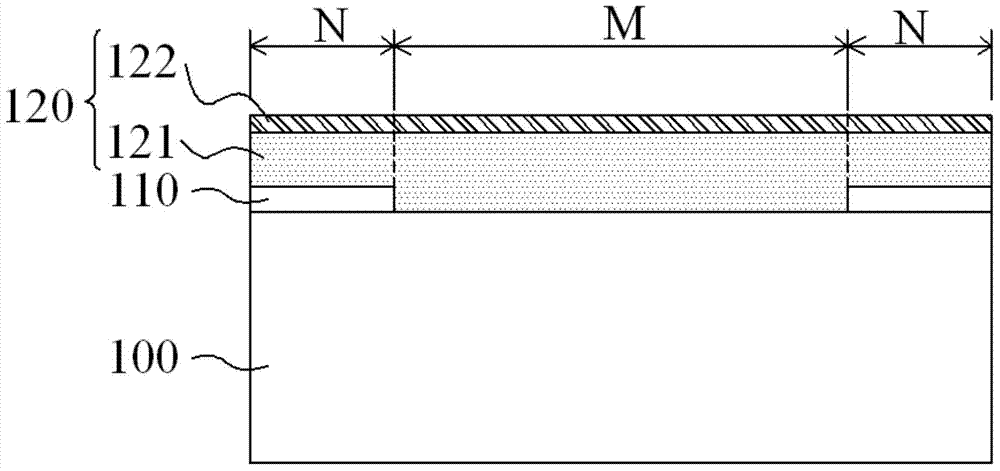

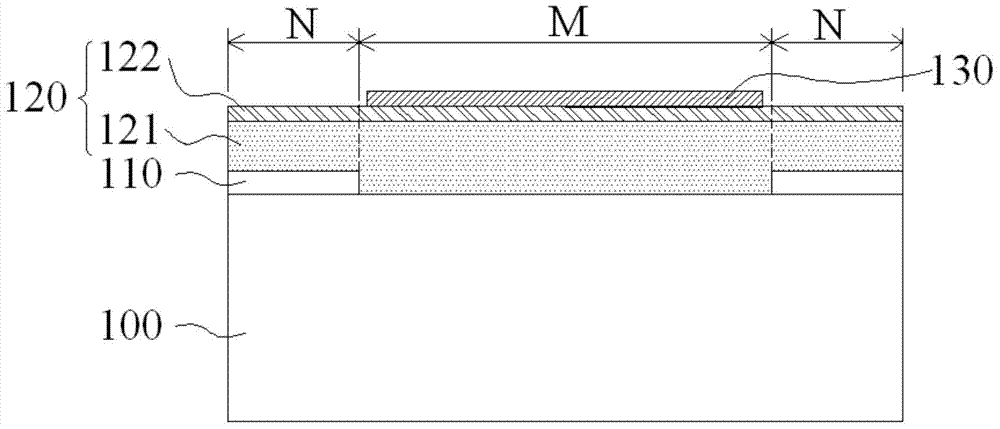

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] The disclosure of the present invention may use repeated element symbols in different embodiments, which does not mean that there is a relationship between different embodiments or drawings. In addition, an element formed "on" or "under" another element may include an embodiment in which the two elements are in direct contact, or an embodiment in which other additional elements are interposed between the two elements. Various elements may be shown in arbitrarily different scales for clarity and simplicity of illustration.

[0042] Figure 1A ~ Figure 1H It is a flowchart of a manufacturing method of a touch panel according to an embodiment of the present invention. in Figure 1H It is also a schematic structural diagram of the touch panel formed by the manufacturing method according to an embodiment of the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com