A kind of gauge ring and its preparation method and application

A high-entropy alloy and diamond technology is applied in the field of gauge ring and its preparation, which can solve the problems of few research literatures, and achieve the effects of controllable alloy composition, high hardness and excellent thermal stability performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

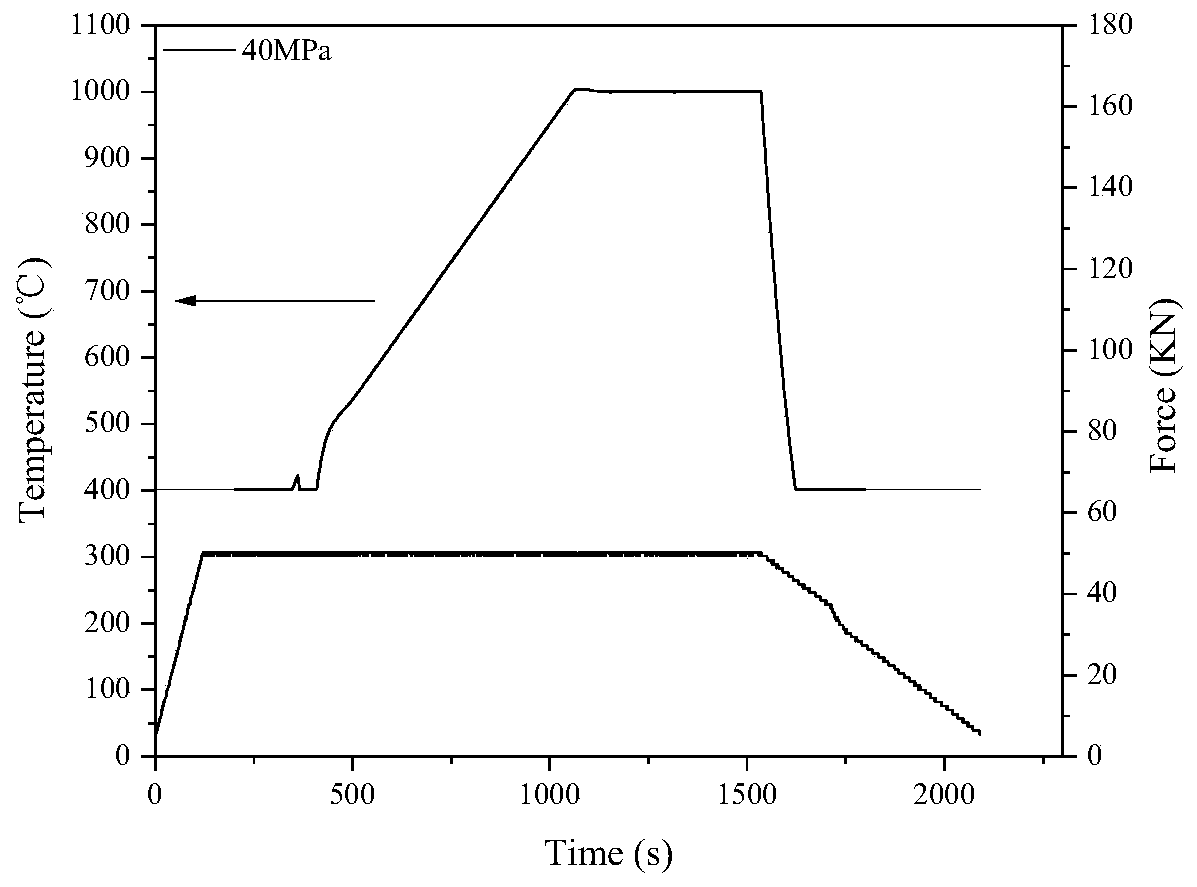

[0055] A kind of high-entropy alloy / diamond composite gauge ring of the present invention, take high-entropy alloy as matrix phase, take diamond as reinforcing phase; Mainly contain Fe, Co, Cr, Ni, Al, Cu6 in the matrix phase high-entropy alloy elements, and the molar amounts of these six elements are equal, and the diamond content is 12wt%.

[0056] The preparation method of the high-entropy alloy / diamond composite gauge ring of the present embodiment comprises the following steps:

[0057] (1) Select Fe, Co, Cr, Ni, Al and Cu plates or blocks with a purity higher than 99.9% (mass percentage), and the molar ratio is Fe:Co:Cr:Ni:Al:Cu=1:1: The ratio of 1:1:1:1 is melted and atomized to obtain high-entropy alloy powder;

[0058] (2) The above-mentioned high-entropy alloy powder is subjected to high-energy ball milling at a rotational speed of 250 rpm for 10 hours. The fluidity of the obtained powder is greater than 20g / s, and the oxygen content is less than 500ppm.

[0059] ...

Embodiment 2

[0065] A kind of high-entropy alloy / diamond composite gage ring of the present invention, take high-entropy alloy as matrix phase, take diamond as reinforcing phase; Mainly contain Fe, Co, Cr, Ni, Al and Cu6 in the matrix phase high-entropy alloy kind of element.

[0066] The preparation method of the high-entropy alloy / diamond composite gauge ring of the present embodiment comprises the following steps:

[0067] (1) Select a plate or block of Fe, Co, Cr, Ni, Al and Cu with a purity higher than 99.9% (mass percentage), and the molar ratio is Fe:Co:Cr:Ni:Al:Cu=1:1 : The ratio of 1:1:0.5:1 is melted and atomized to obtain high-entropy alloy powder;

[0068] (2) The above-mentioned high-entropy alloy powder was subjected to high-energy ball milling at a rotational speed of 250 rpm for 16 hours. The fluidity of the obtained powder is greater than 20g / s, and the oxygen content is less than 500ppm.

[0069] (3) According to the mass ratio of high-entropy alloy: diamond = 4:1, the...

Embodiment 3

[0075] A kind of high-entropy alloy / diamond composite gage ring of the present invention, take high-entropy alloy as matrix phase, take diamond as reinforcing phase; Mainly contain Fe, Co, Cr, Ni, Al and Cu6 in the matrix phase high-entropy alloy kind of element.

[0076] The preparation method of the high-entropy alloy / diamond composite gauge ring of the present embodiment comprises the following steps:

[0077] (1) Select a plate or block of Fe, Co, Cr, Ni, Al, Cu and Zn with a purity higher than 99.9% (mass percentage), and the molar ratio is Fe:Co:Cr:Ni:Al:Cu:Zn = 1: 1: 1: 1: 0.5: 0.5: 1 ratio is melted and atomized to obtain high-entropy alloy powder;

[0078] (2) The above-mentioned high-entropy alloy powder was subjected to high-energy ball milling at a rotational speed of 250 rpm for 18 hours. The fluidity of the obtained powder is greater than 20g / s, and the oxygen content is less than 500ppm.

[0079] (3) According to the mass ratio of high-entropy alloy: diamond ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxygen content | aaaaa | aaaaa |

| Average microhardness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com