Method for manufacturing metal composite pipe blank and device for manufacturing metal composite pipe blank

A technology of metal composite pipe and manufacturing method, which is applied in the field of devices for manufacturing metal composite pipe blanks and devices for manufacturing metal pipe blanks, and can solve problems such as affecting the heat conduction performance of products, high cost, and difficulty in exerting the effectiveness of copper-aluminum composite pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention provides a method for manufacturing a metal composite tube blank and a device for manufacturing a metal composite tube blank. Taking the copper-aluminum composite tube manufactured by the method of the invention as an example, the manufacture of the metal composite tube blank in the present invention will be described in detail. Method and device for manufacturing metal composite tube blank.

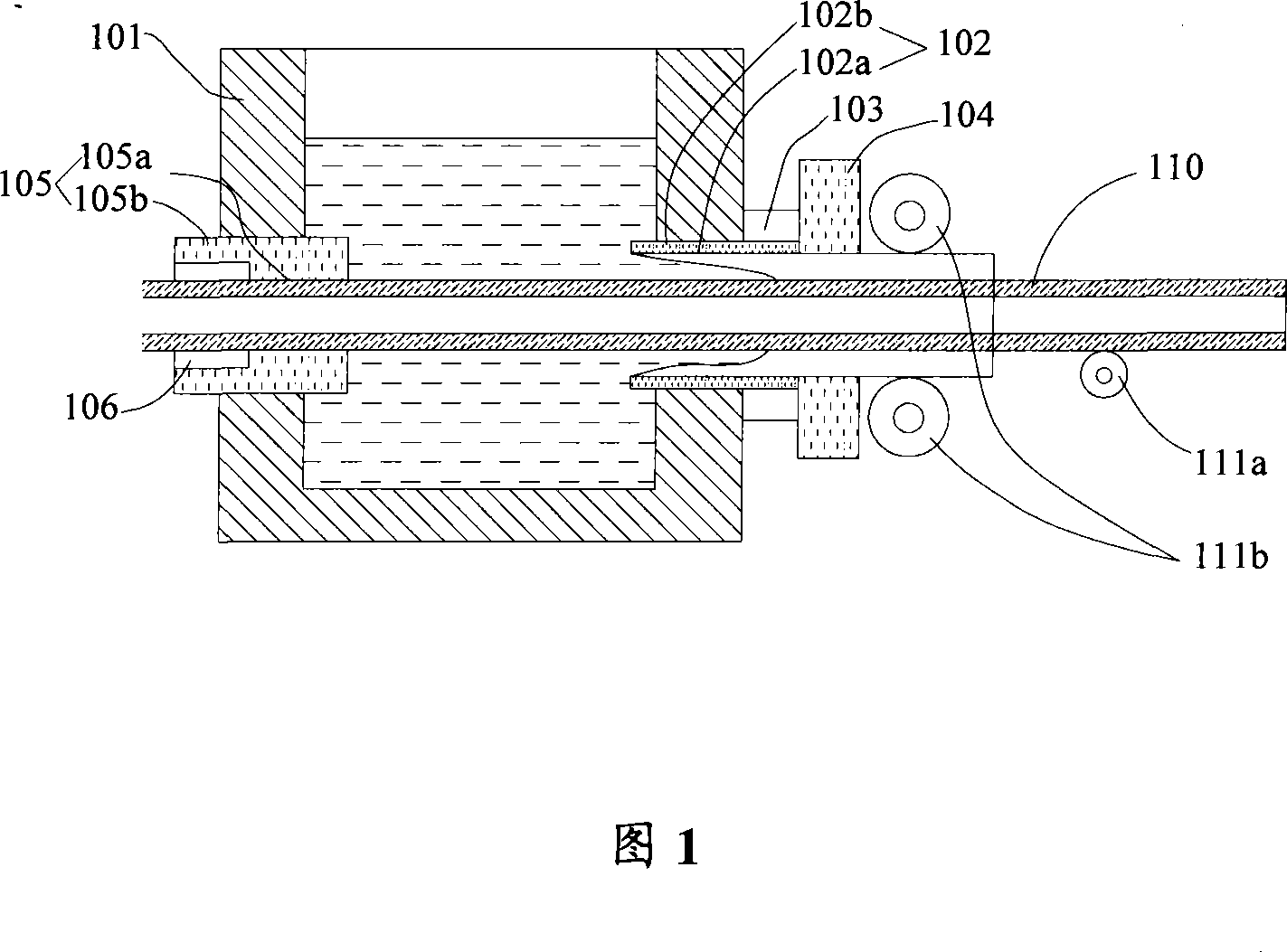

[0028] Referring to Fig. 1, this figure is the schematic diagram of manufacturing copper-aluminum composite pipe according to the first embodiment of the present invention, continuous casting mold 102 is installed on the side wall of constant temperature furnace 101, and the diameter of hole that comprises central axis on the continuous casting mold 102 and keeps horizontal is The circular mold hole 102a of 80mm and the mold cover 102b that stretches into the thermostatic furnace; The first cooler 103 that is used to solidify the molten aluminum by cooling the mold ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com