Method for preparing aluminum or aluminum-tin alloy plated layer on surface of sintered neodymium-iron-boron permanent magnet

A technology of aluminum-tin alloy and neodymium-iron-boron, which is applied in the direction of metal material coating process, coating, sputtering plating, etc., can solve the problems of reduced coating adhesion, limited coating types and protective capabilities, and weakened protective performance. , to achieve good binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Place the processed ultra-high-performance sintered NdFeB magnet blank with a grade of 40EH in a degreasing solution for surface degreasing, and the degreasing time is 10 minutes; then grind and polish the degreased NdFeB substrate , cleaned with a nitric acid solution with a mass fraction of 3%, and ultrasonically cleaned the substrate in a pure alcohol solution for 30 minutes, and put the cleaned NdFeB substrate into an oven for drying at a temperature of 120 ℃, time is 20 minutes;

[0021] (2) Put the sintered NdFeB substrate into the magnetron sputtering ion plating equipment, the distance from the substrate to the pure aluminum target is 12cm, turn on the ion plating equipment and cooling circulating water; vacuum the ion plating equipment to 1×10 -3 Pa, then pass in argon gas, control the flow rate of argon gas, adjust the air pressure in the chamber to 2Pa, and use 800V bias power supply for glow discharge cleaning for 20 minutes;

[0022] (3) Adjust the bia...

Embodiment 2

[0029] (1) Place the processed ultra-high-performance sintered NdFeB magnet blank with a grade of 40EH in a degreasing solution for surface degreasing, and the degreasing time is 10 minutes; then grind and polish the degreased NdFeB substrate , cleaned with a nitric acid solution with a mass fraction of 3%, and ultrasonically cleaned the substrate in a pure alcohol solution for 30 minutes, and put the cleaned NdFeB substrate into an oven for drying at a temperature of 120 ℃, time is 20 minutes;

[0030] (2) Put the sintered NdFeB substrate into the magnetron sputtering ion plating equipment, the distance from the substrate to the pure aluminum target is 12cm, turn on the ion plating equipment and cooling circulating water; vacuum the ion plating equipment to 1×10 -3 Pa, then pass in argon gas, control the flow rate of argon gas, adjust the air pressure in the chamber to 2Pa, and use 800V bias power supply for glow discharge cleaning for 20 minutes;

[0031] (3) Adjust the bia...

Embodiment 3

[0039] Step in embodiment 2 The vacuum heat treatment furnace is changed into a non-vacuum heat treatment furnace, and all the other processes are the same as in Example 2.

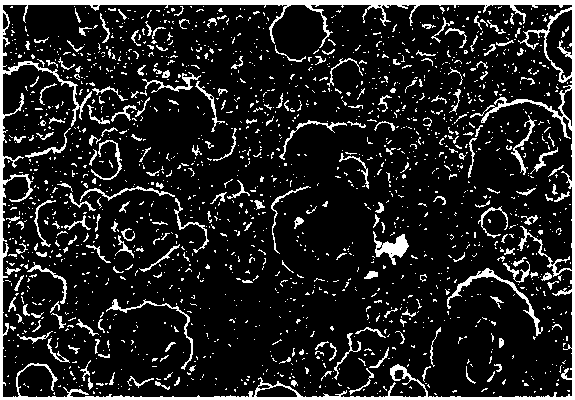

[0040] The surface morphology of the aluminum protective coating on the surface of the sintered NdFeB permanent magnet prepared by the above procedure is as follows: image 3 , and its properties are shown in Table 3-1 and Table 3-2:

[0041]

[0042]

[0043] According to Table 3-1 and Table 3-2, it can be concluded that when the non-vacuum heat treatment temperature is 530°C, the corrosion resistance and bonding force of the coating are better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com