Solder for welding carbon/silicon carbide ceramic matrix composite material and titanium-aluminum-based alloy and soldering method

A technology of silicon carbide ceramic matrix and composite materials, which is applied in the field of solder and brazing for welding carbon/silicon carbide ceramic matrix composite materials and titanium-aluminum-based alloys. It can solve the problems of complex process and low service temperature, and reduce residual stress. , high welding strength and high welding production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

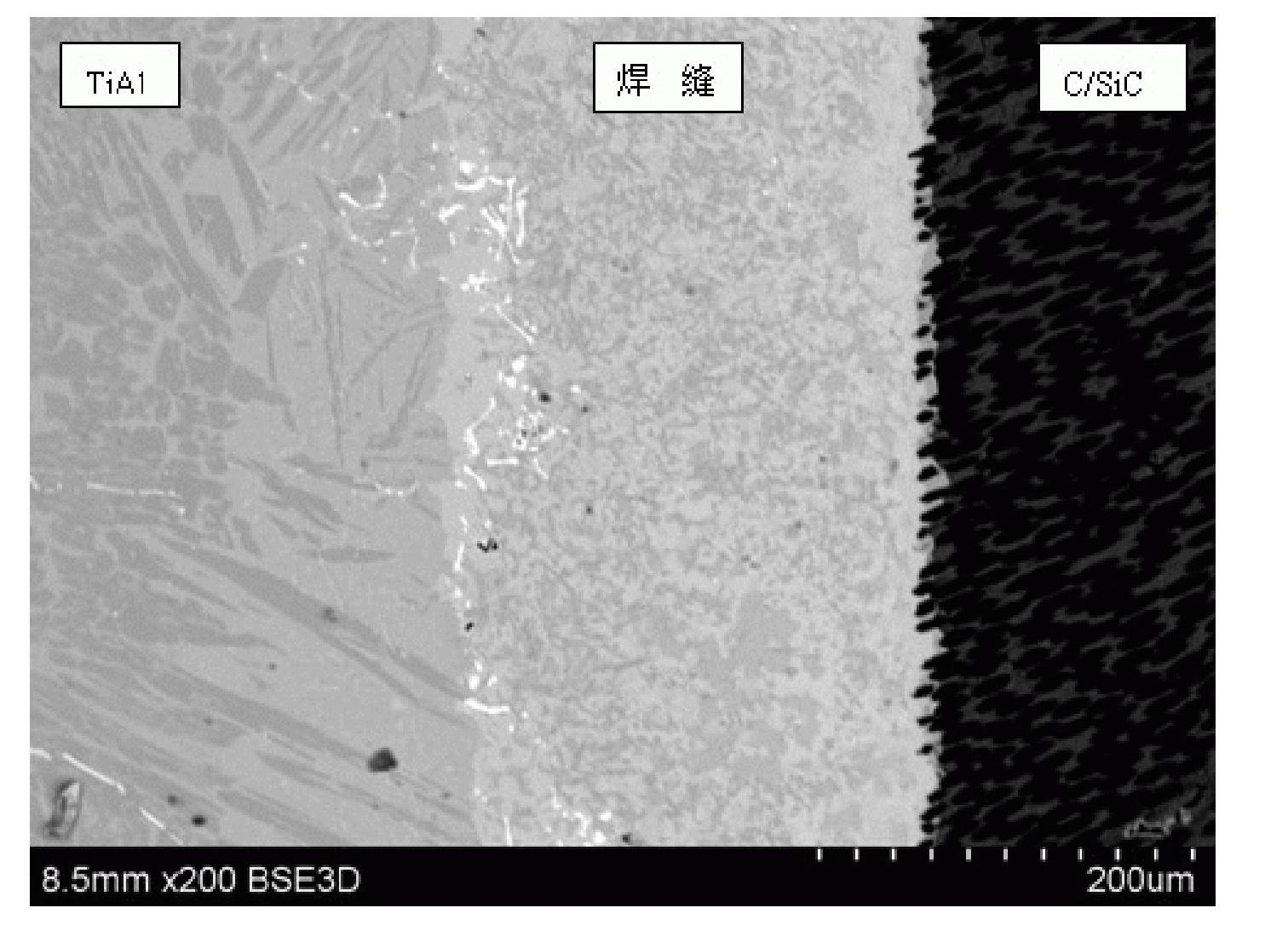

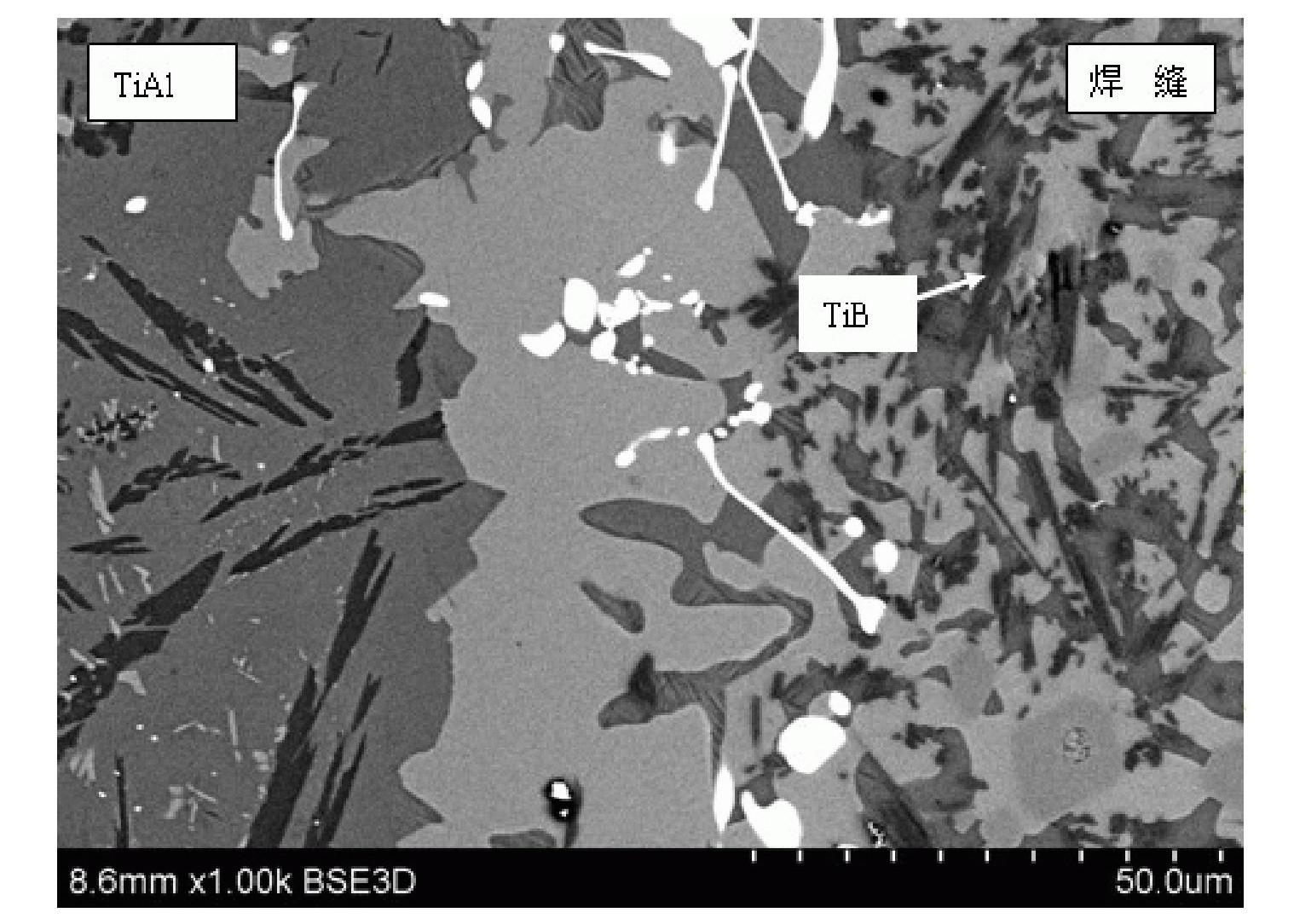

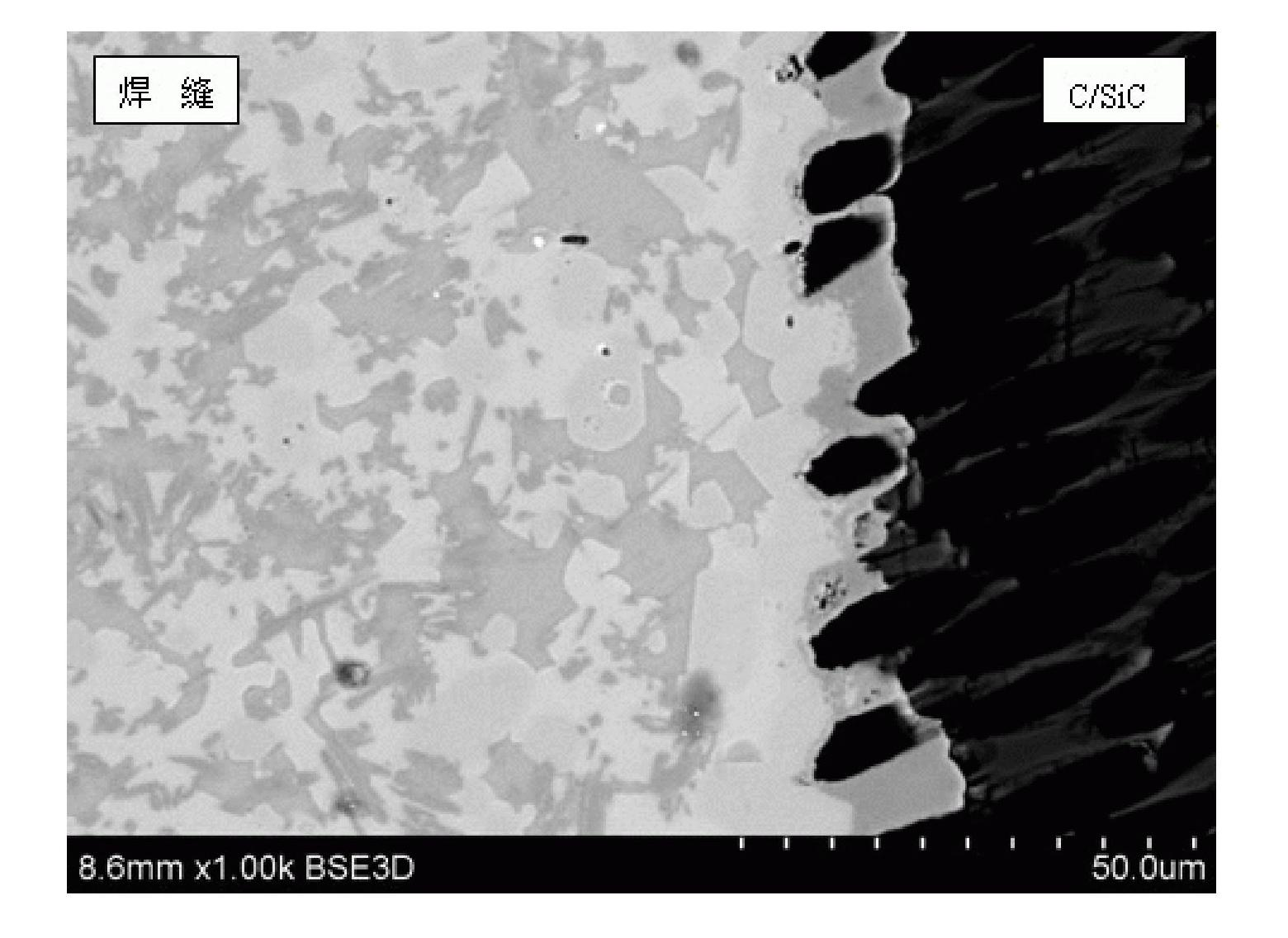

[0012] The brazing material for welding carbon / silicon carbide ceramic matrix composite material and titanium-aluminum-based alloy in this embodiment makes the carbon / silicon carbide ceramic-based composite material and titanium-aluminum-based alloy directly in-situ composite reaction brazed connection, the welding strength is high, and the joint room temperature is high. The shear strength reaches 40MPa~105MPa, and the shear strength at 600°C reaches 30MPa~70MPa, and the service temperature is higher than 600°C.

[0013] Embodiment 2: This embodiment differs from Embodiment 1 in that: the fineness of the nickel powder, titanium powder, titanium dihydride powder or boron powder is 200 mesh to 400 mesh. Others are the same as in the first embodiment.

specific Embodiment approach 2

[0014] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the fineness of the nickel powder, titanium powder, titanium dihydride powder or boron powder is 300 mesh. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 4: The difference between this embodiment and Embodiments 1 to 3 is that the brazing filler metal for welding carbon / silicon carbide ceramic matrix composite material and titanium-aluminum base alloy consists of 100 parts by mass of titanium material powder, 70 parts ~160 parts of nickel powder and 2~10 parts of boron powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com