Feed source for microwave antenna and microwave antenna

A technology for microwave antennas and feeds, applied to antennas, antenna supports/mounting devices, electrical components, etc., can solve the problems of increased difficulty and cost in mass production, reduce shading loss, ensure consistency, and overcome technical problems the effect of prejudice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation examples, but it is not intended to limit the technical solution of the present invention.

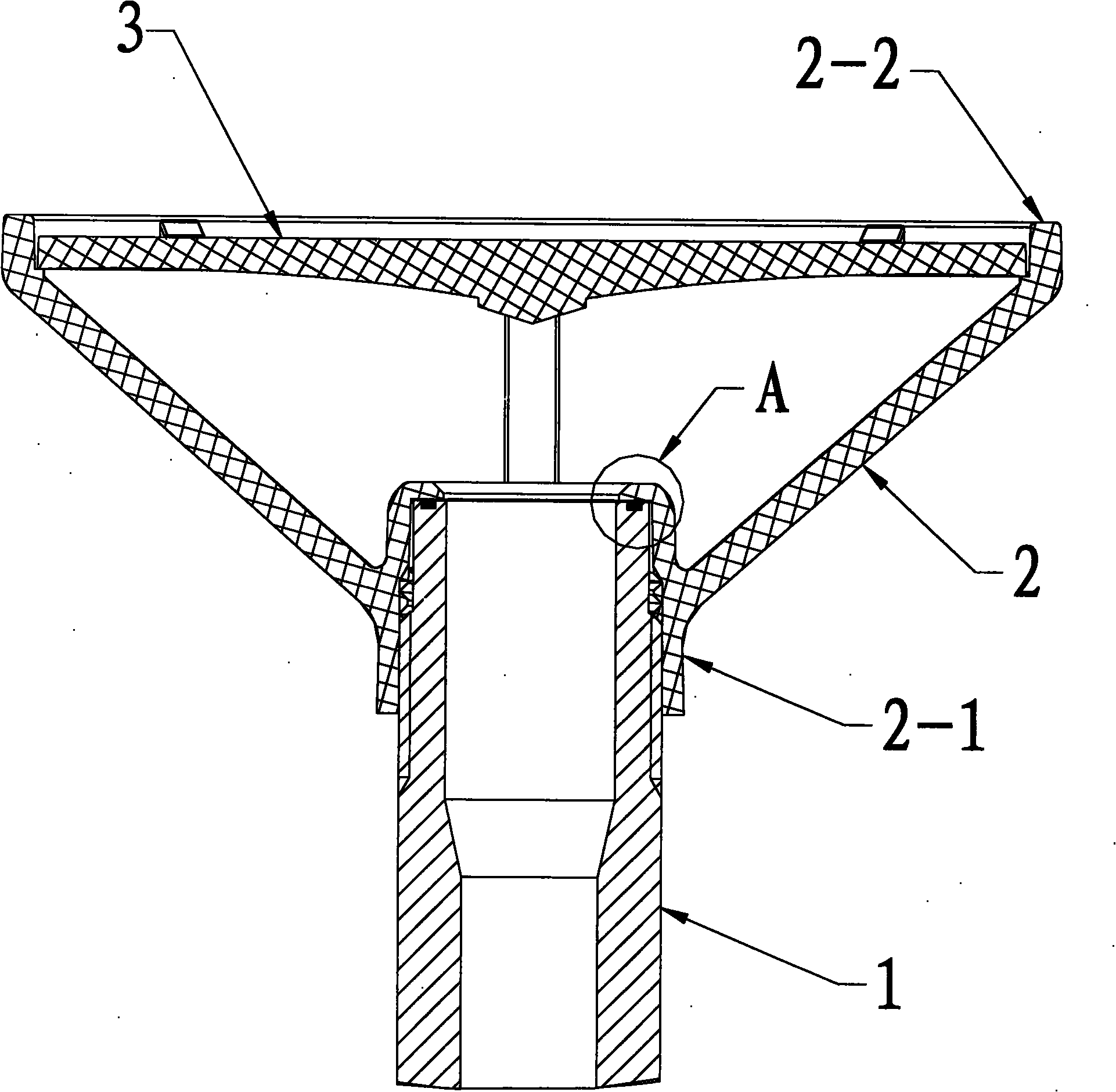

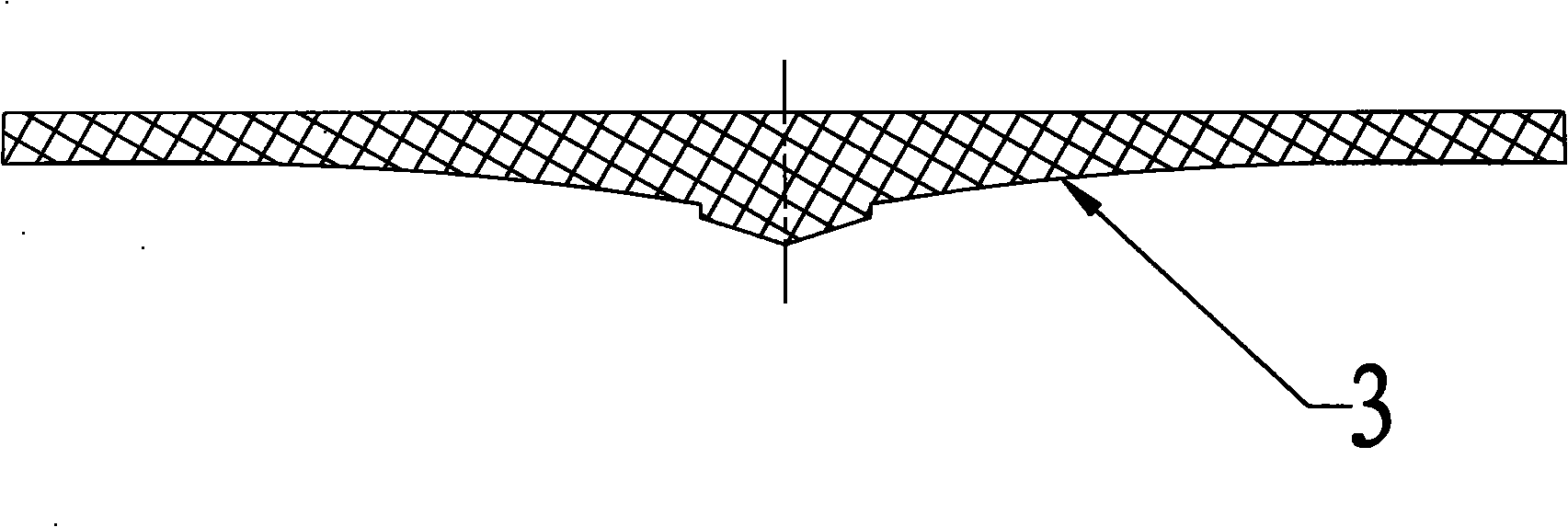

[0043] Such as figure 1 As shown, the microwave antenna feed source of the present invention is closely connected to the feed horn 1 through the first connection part 2-1 of the support frame 2, and connected to the secondary reflector 3 through the second connection part 2-2 of the support frame 2, and feeds The horn 1 and the secondary reflector 3 are on the same central axis.

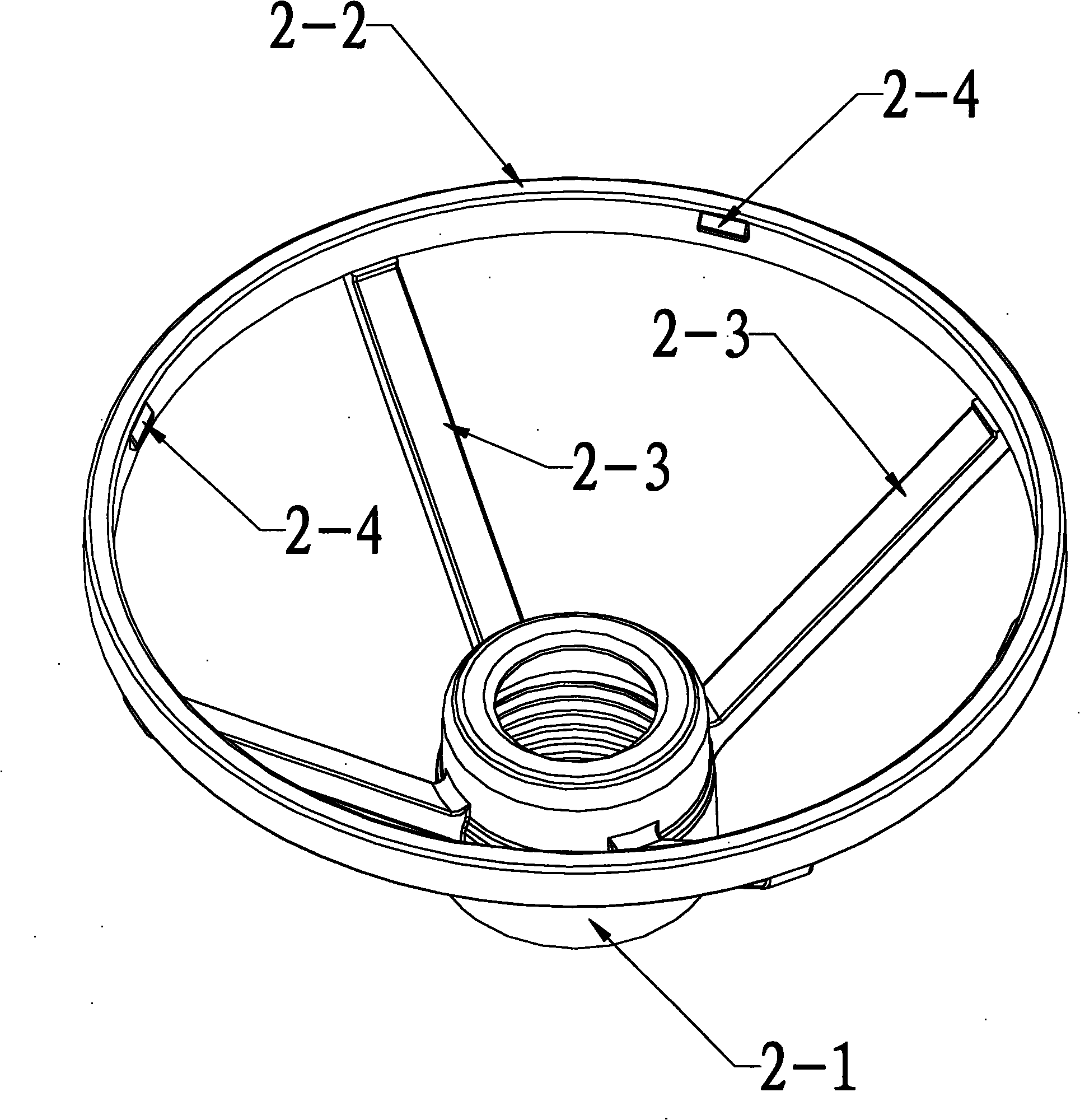

[0044] Such as figure 2 As shown, the support frame 2 of the present embodiment preferably has four support columns 2-3, and the four support columns 2-3 are connected and fixed to the first connection part 2-1 and the second connection part 2-2, and the second connection part 2 -2 is a ring that can just accommodate the sub-reflecting surface 3, and four evenly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com