PERC cell back surface passive film layer and PERC cell preparation method based on ALD process

A backside passivation and backside technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problems of reducing the electrical performance of cells, the impact of light decay on cells, and the deterioration of passivation effects, etc., to shorten the manufacturing process , Improve battery appearance and increase productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

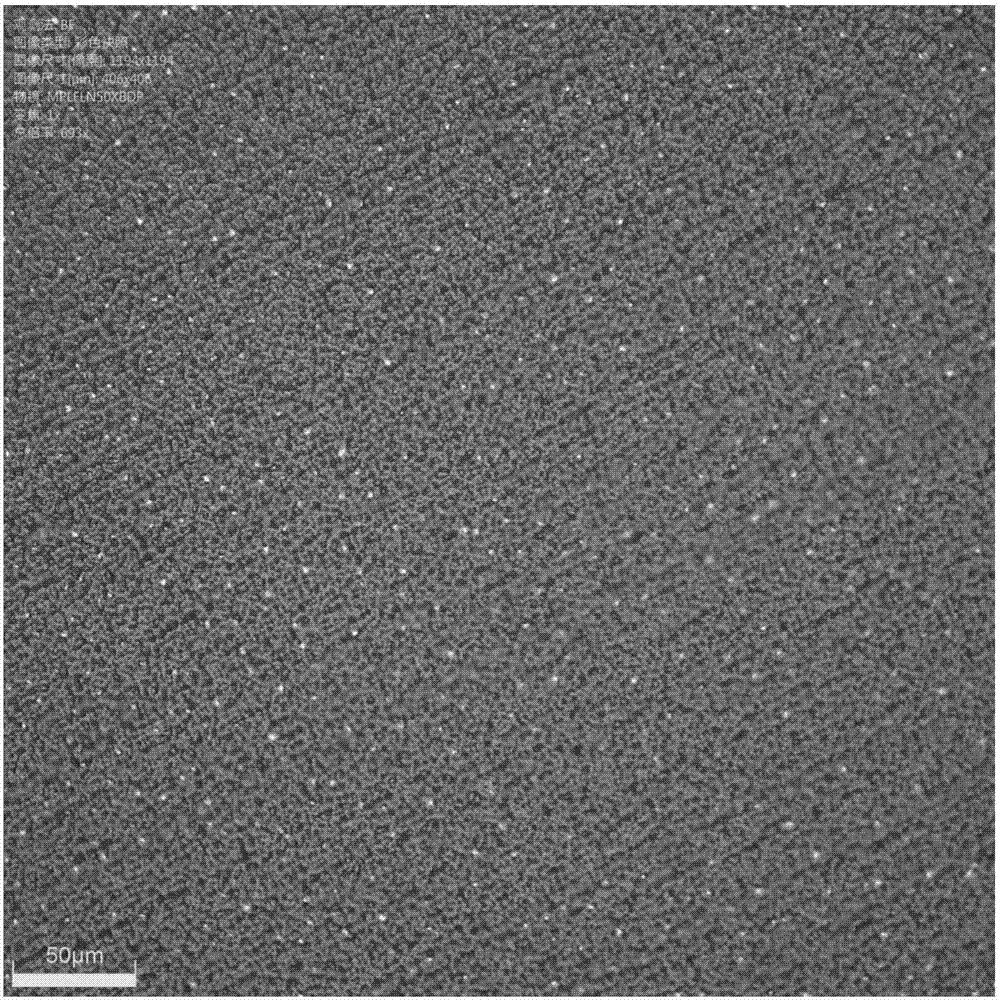

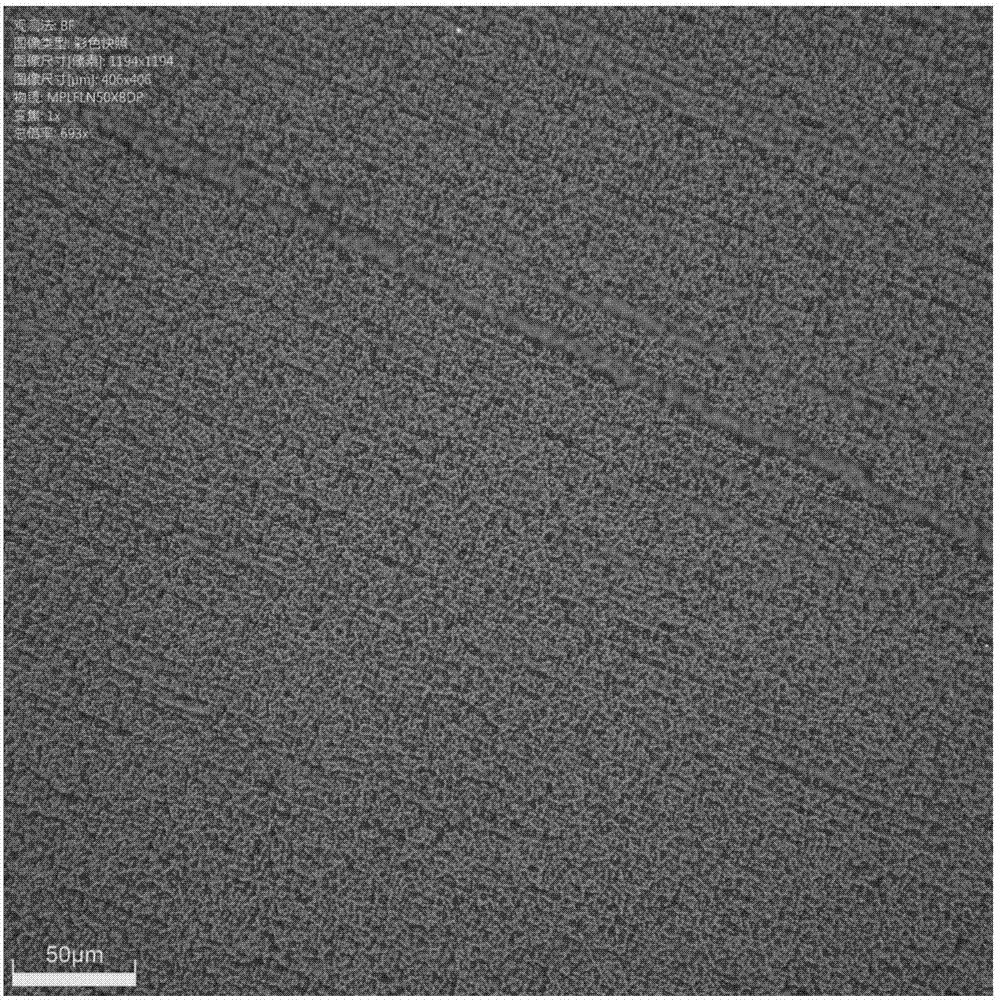

[0025] Such as Figure 5 As shown, a PERC battery back passivation film layer of the present invention includes a back aluminum oxide layer 2, a back SiONx layer 3 and a back SiNx layer 4 successively deposited on the surface of a silicon substrate 1 of a PERC battery outward, and contains the passivation film layer. The preparation method of the PERC battery based on the ALD process of the chemical film layer, including the steps: 1) alkali texturing of single crystal silicon sheet; 2) diffusion; 3) back polishing, etching and dephosphorous silicon glass; 4) preparation of aluminum oxide by back ALD ;5) Deposit SiNx anti-reflection film by PECVD on the front; 6) Deposit SiONx and SiNx laminated film by PECVD on the back, after the graphite boat is loaded into the PECVD furnace tube, the temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com