Electrostatic spinning method for preparing interlayer nano-fabric and device thereof

A spinning device and electrostatic spinning technology, applied in the direction of non-woven fabrics, layered products, textiles and papermaking, etc., to achieve the effect of easy operation and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

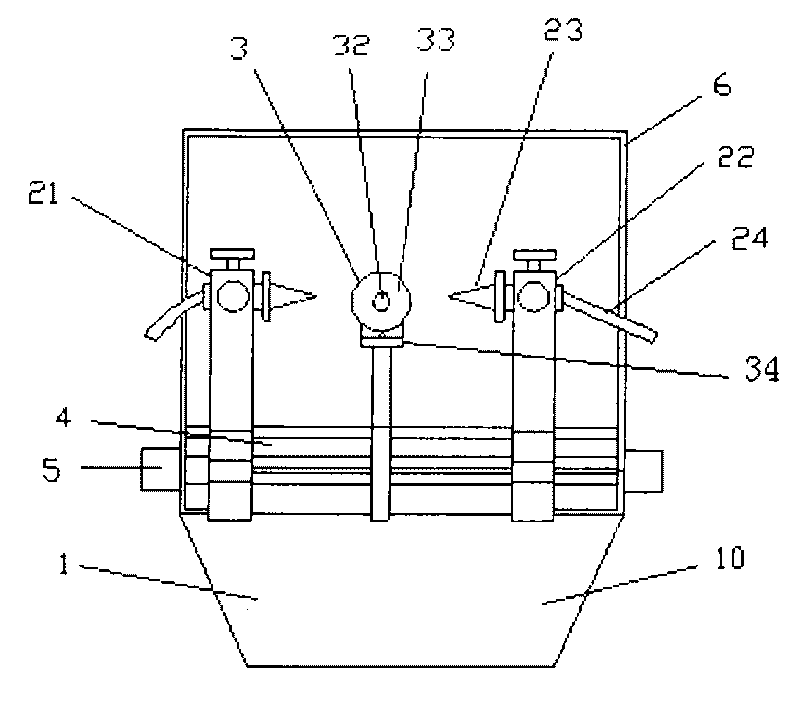

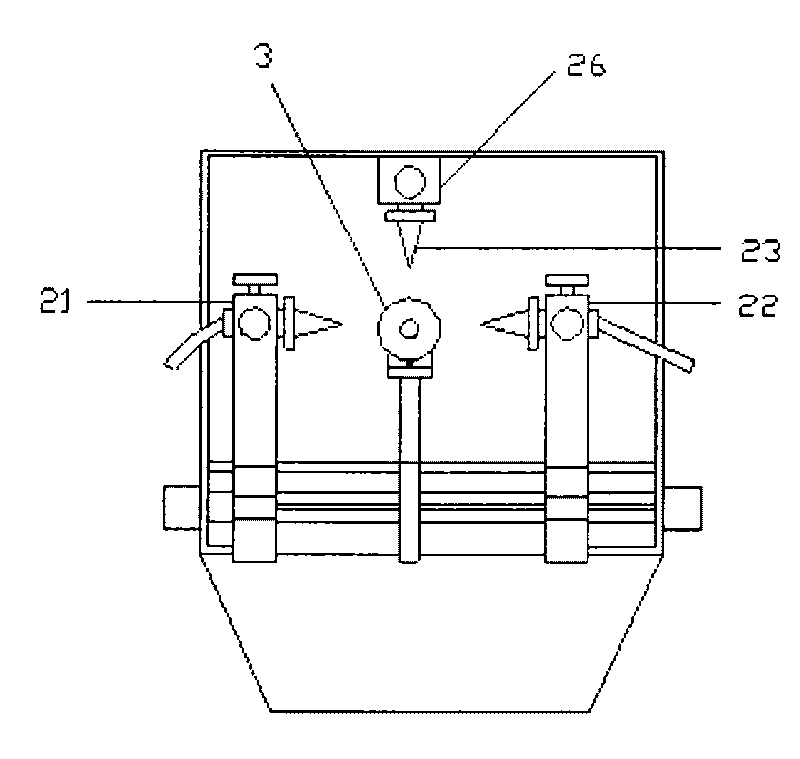

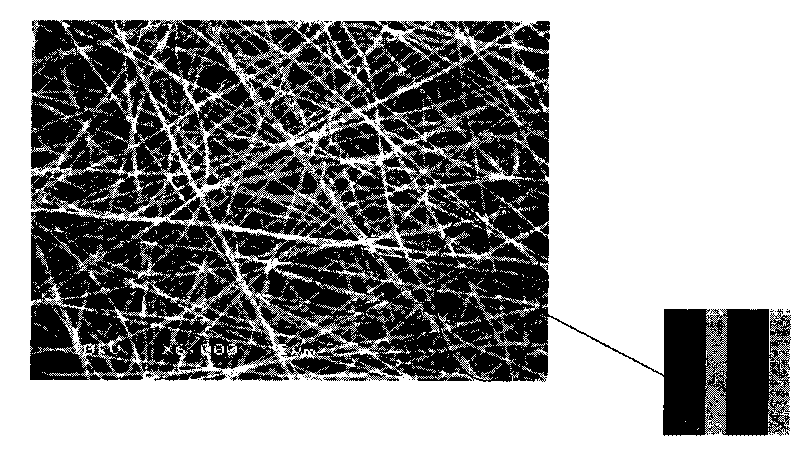

[0043] Example 1: Using the above electrospinning device to prepare PET and PAN interlayer nanofiber nonwovens

[0044] A certain quality of polyester chips (PET) is dissolved in trifluoroacetic acid and methylene chloride in a mixed solvent with a volume ratio of 4:1, the mass percentage of the solution is 13%, and it becomes a stable and uniform solution at room temperature, ready for use ; A certain quality of polyacrylonitrile (PAN) is dissolved in N, N-dimethylformamide (DMF), the mass percent of the solution is 10%, at room temperature into a stable, uniform solution, stand-by; the above The PET solution is injected into the first spinning device 21 through the liquid supply device, and the above-mentioned PAN solution is injected into the second spinning device 22 through the liquid supply device.

[0045] The distance between the spinneret 23 and the roller device 33 was 15 cm. The two spinnerets are respectively connected with voltages of 18kV and -15kV, which respec...

Embodiment 2

[0048] The same device and method as in Example 1 were used to prepare PET nanofiber non-woven fabrics.

[0049] First, a certain quality of polyester chips (PET) is dissolved in a mixed solvent with a volume ratio of trifluoroacetic acid and dichloromethane of 4:1, the mass percentage of the solution is 13%, and stirred at room temperature until it dissolves into a stable, uniform solution, and after standing for a few minutes, inject the above solution into the two jetting devices. Wherein, the distance between the spinneret and the roller device 33 is 13.5cm; the frequency of the reciprocating motion of the roller device 33 parallel to the axial direction of the roller device is 2 times / min; the rotational speed of the roller device 33 around the axial direction 200 revolutions per minute; electrospinning was performed at voltages of 18kV and -18kV respectively to obtain PET nanofiber non-woven fabrics.

Embodiment 3

[0051] The same device and method as in Example 1 were used to prepare PAN nanofiber non-woven fabrics.

[0052] First, a certain mass of polyacrylonitrile (PAN) is dissolved in N,N-dimethylformamide (DMF), the mass percentage of the solution is 10%, and it becomes a stable and uniform solution at room temperature, and it is left to stand for a few minutes Afterwards, inject the above solution into the two injection devices. Wherein, the distance between the spinneret and the roller device 33 is 13.5cm; the frequency of the reciprocating motion of the roller device 33 parallel to the axial direction of the roller device 33 is 2 times / min; The rotating speed is 200 rpm; electrospinning is carried out at voltages of 15kV and -15kV respectively to obtain PAN nanofiber nonwoven fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com