Polyvinyl chloride (PVC) drip irrigation belt

A polyvinyl chloride and drip irrigation tape technology, which is applied in application, climate change adaptation, gardening, etc., can solve problems such as low elongation at break and impact strength, difficulty in making drip irrigation tapes that meet standards, and increased operating costs for enterprises. Achieve the effects of reducing melt viscosity, realizing high quality, and improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A polyvinyl chloride (PVC) drip irrigation belt is made of raw materials containing the following components (parts by weight, the same below)

[0031] PVC (SG-2 type) 100

[0032] DOP 20

[0033] OPE 1

[0034] CPE 3

[0035] ACR-401 2.5

[0036] DOTTG 2

[0037] Aluminate coupling agent 0.5

[0038] Ultrafine CaCO 3 10

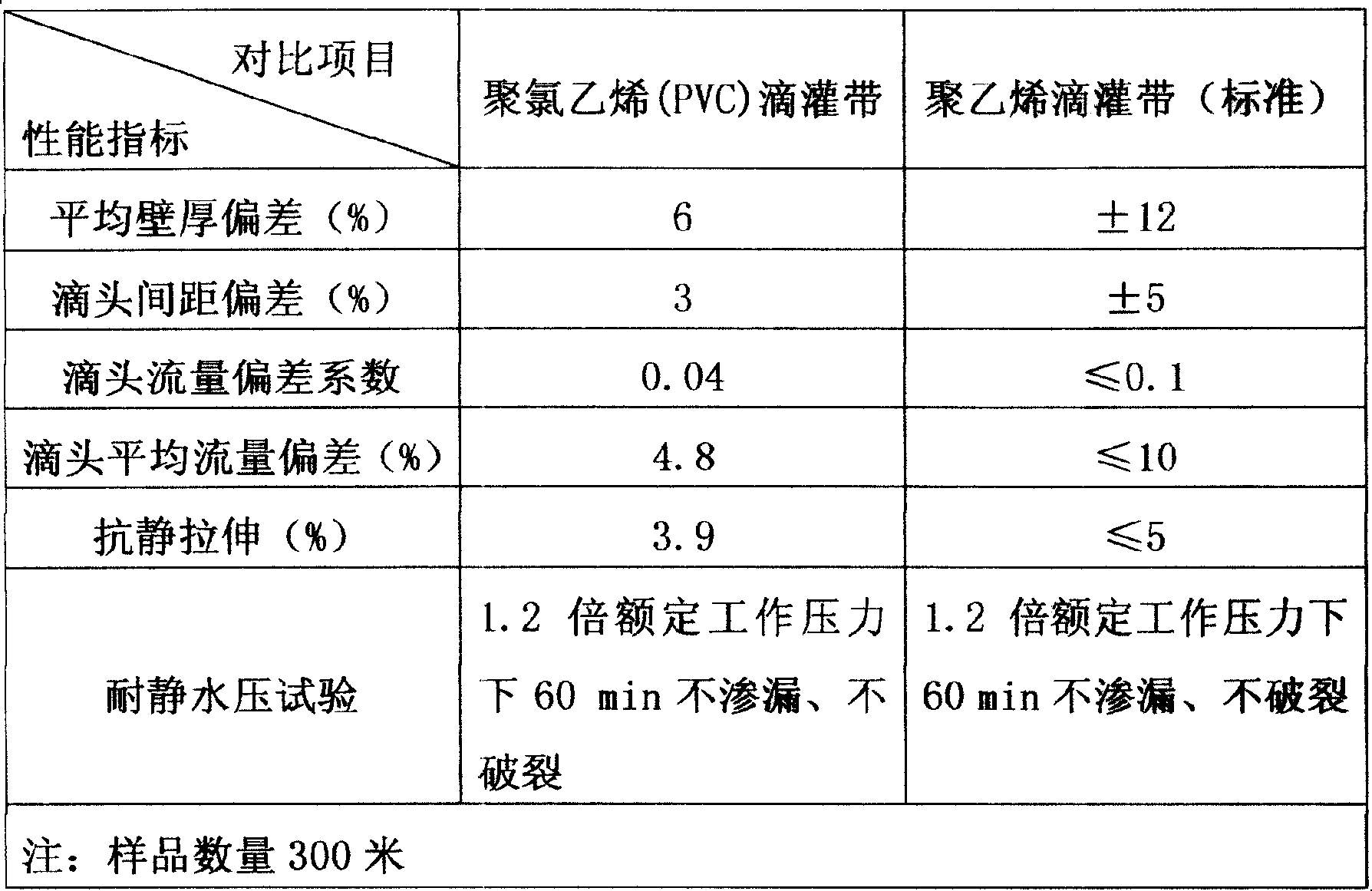

[0039] The process flow is: after weighing according to the formula, put it into the high-speed mixer, rely on friction to heat it up to 110-120°C, knead at high speed and discharge to low-speed cold stirring, and discharge after cooling to 45°C for standby. Start the twin-screw In the granulator, heat up to 160-180°C, add the above-mentioned mixed powder into the granulator to granulate, and set aside. Raise the temperature of the main machine of the drip irrigation belt to 160-195°C, add the above-mentioned prepared pellets, plasticize, filter and extrude to form a polyvinyl chloride (PVC) drip irrigation belt. Take samples for testi...

Embodiment 2

[0045] In this embodiment, the polyvinyl chloride (PVC) drip irrigation belt is made of raw materials containing the following components:

[0046] PVC (SG-3 type) 100

[0047] DOP 25

[0048] OPE0.5

[0049] Carbon black 0.5

[0050] CPE 5

[0051] ACR-401 2

[0052] DOTTG 2.5

[0053]Aluminate coupling agent 0.6

[0054] Light CaCO 3 15

[0055] The preparation process is the same as in Example 1. Detection method is according to embodiment 1, and test result is shown in table 2

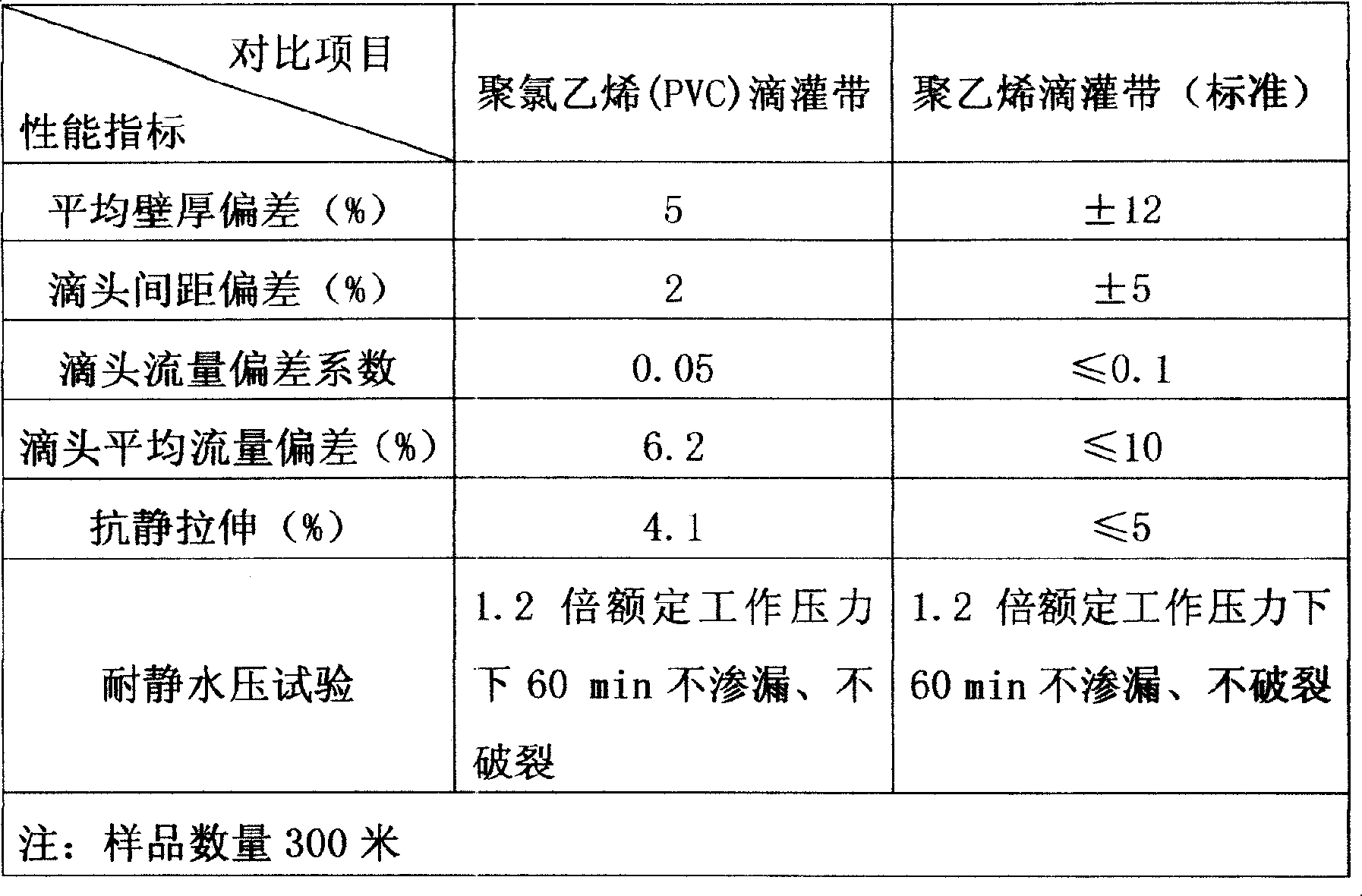

[0056] Table 2 Performance comparison of polyvinyl chloride (PVC) drip irrigation tape and polyethylene drip irrigation tape

[0057]

[0058] It can be seen from Example 2 that all the performances of this PVC drip irrigation tape meet the testing standards of QB / T 2517-2001.

Embodiment 3

[0060] In this embodiment, the polyvinyl chloride (PVC) drip irrigation belt is made of raw materials containing the following components:

[0061] PVC (SG-3 type) 100

[0062] DOP 28

[0063] stearic acid 1

[0064] carbon black 1

[0065] EVA 6

[0066] ACR-401 3

[0067] DBTL 1.5

[0068] Titanate coupling agent 0.8

[0069] Light CaCO 3 20

[0070] The preparation process is the same as in Example 1. Detection method is according to embodiment 1, and test result is shown in table 3

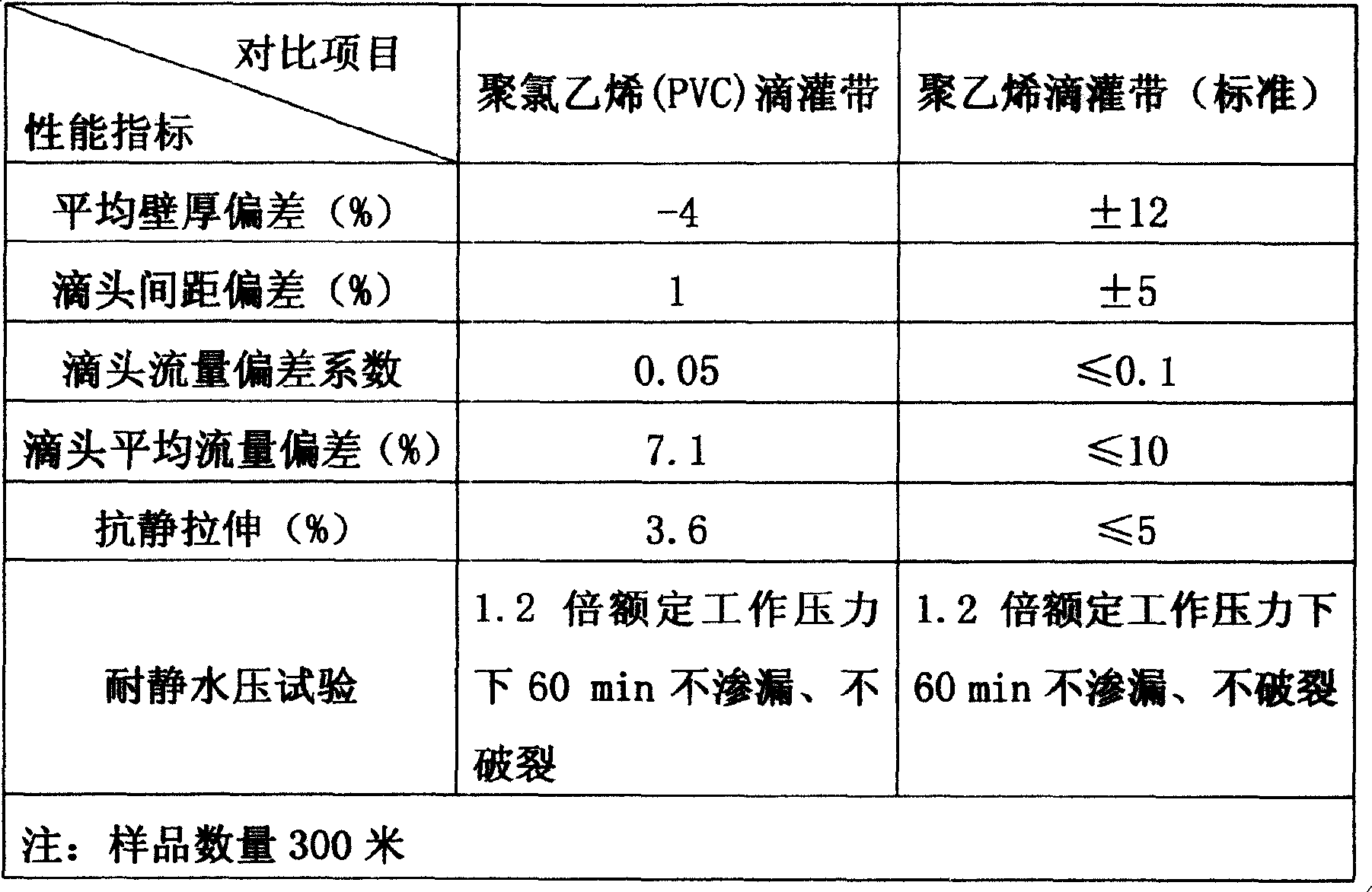

[0071] Table 3 Performance comparison between polyvinyl chloride (PVC) drip irrigation tape and polyethylene drip irrigation tape

[0072]

[0073] As can be seen from Example 3, the various properties of this polyvinyl chloride (PVC) drip irrigation tape all meet the QB / T2517-2001 testing standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com