Method for synthesizing 2-amido-6-chloropurine

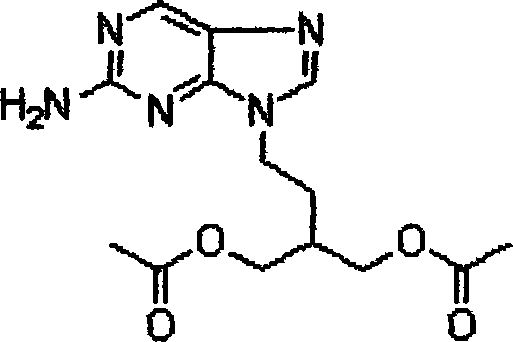

A synthetic method, the technology of chloropurine, applied in the direction of organic chemistry, etc., can solve the problems of low product yield, side reactions, affecting the yield and purity of 2-amino-6-chloropurine, etc., and achieve a reasonable and high synthetic process. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

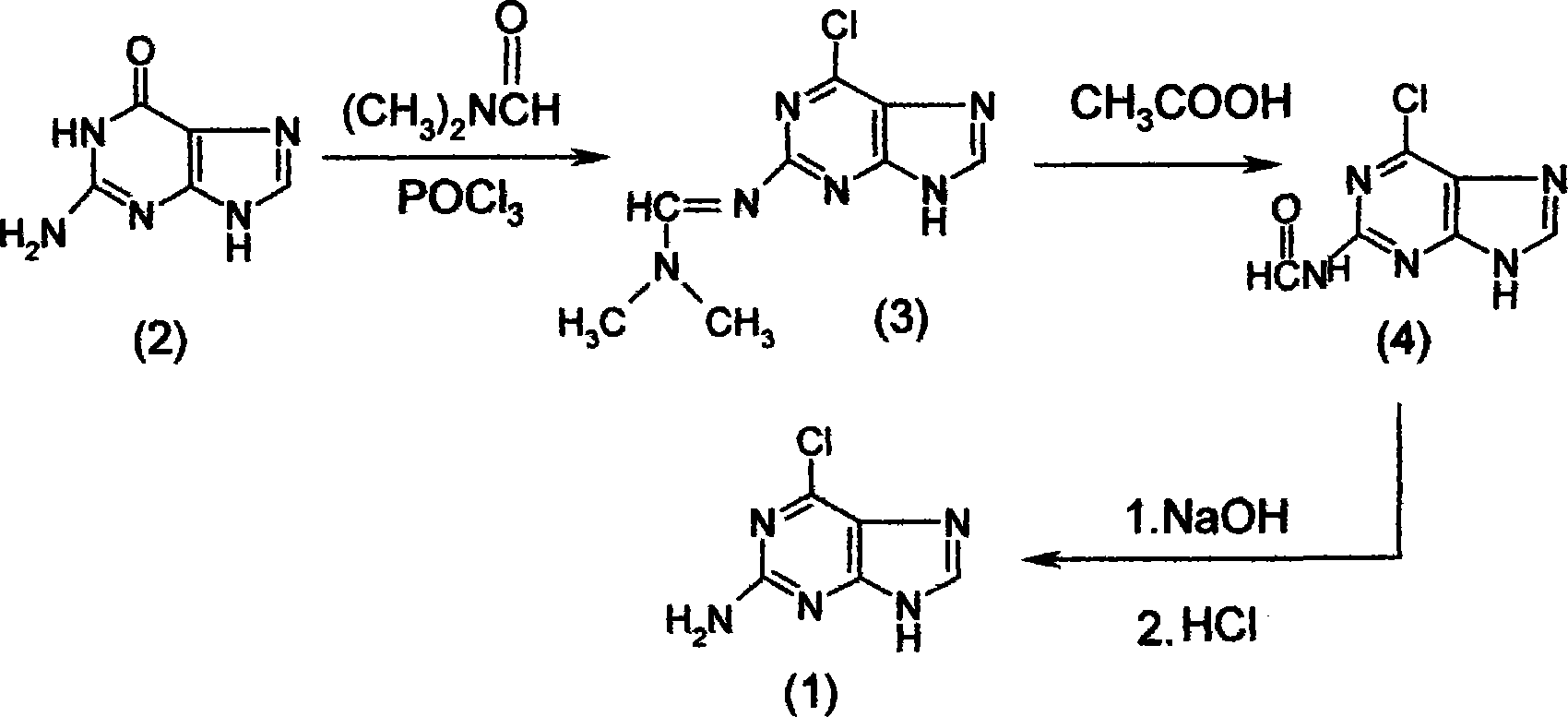

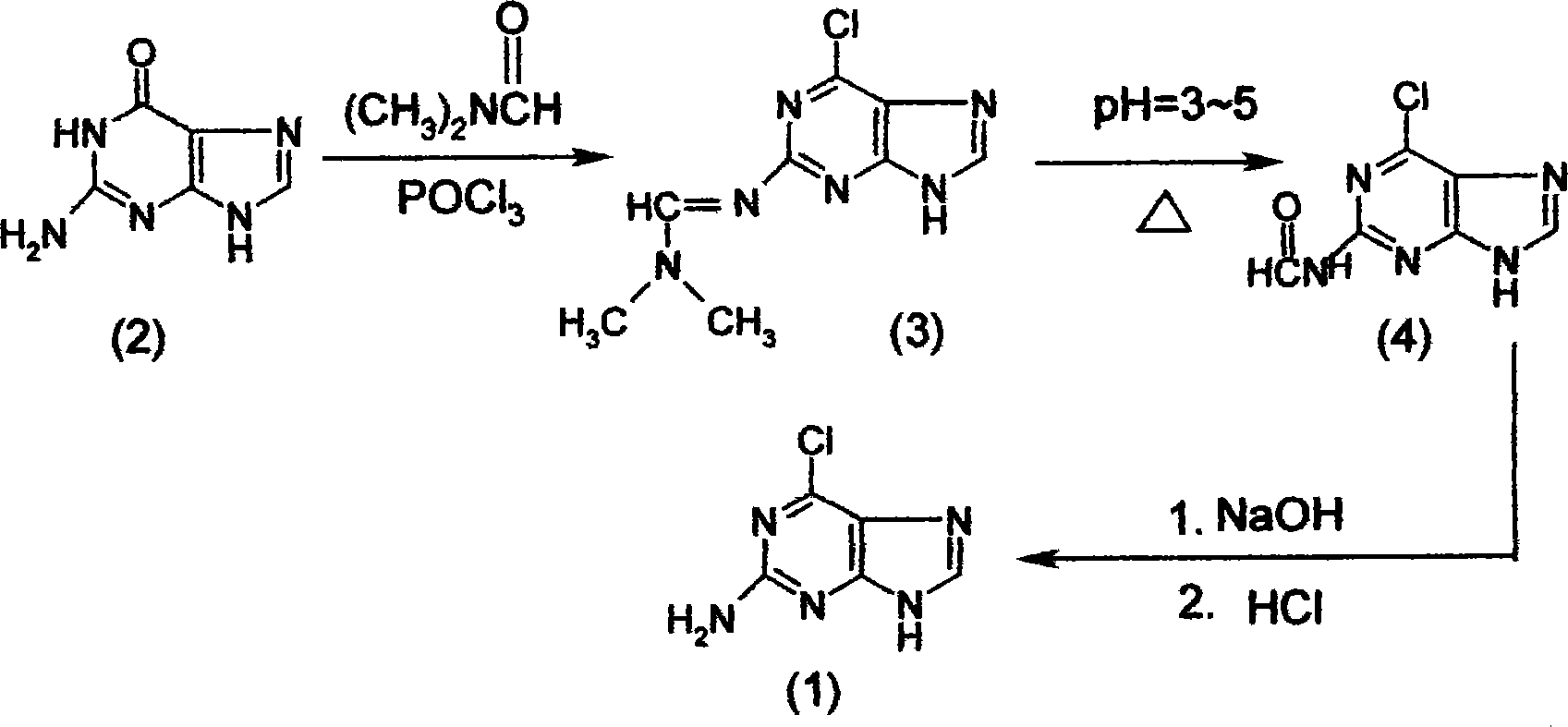

[0045] The synthesis of embodiment one 2-amino-6-chloropurine (1)

[0046] The synthetic method of 2-amino-6-chloropurine (1) comprises the following steps successively:

[0047] a) Preparation of 2-dimethylaminomethenimino-6-chloropurine (3)

[0048] First add 40mL of N,N-dimethylformamide to the dry reaction bottle, and add 35mL of POCl dropwise at 0℃~10℃ 3 , formulated as POCl 3 N,N-dimethylformamide solution, set aside; then in another dry reaction bottle, add 200mL of 1,2-dichloroethane and 20g of guanine (2), at 20℃~30℃ , dropwise add the prepared N,N-dimethylformamide solution of phosphorus oxychloride. After dripping, keep stirring for 1 hour, then heat up and reflux for 5 to 8 hours to complete the reaction, and cool to obtain 2-dimethylaminomethenimino-6-chloropurine (3). The intermediate product (3) does not need to be prepared from the reaction solution Separated from, the reaction solution containing the intermediate product (3) is for subsequent use;

[0049...

Embodiment 2

[0056] The synthesis of embodiment two 2-amino-6-chloropurine (1)

[0057] The synthetic method of 2-amino-6-chloropurine (1) comprises the following steps:

[0058] a) Preparation of 2-dimethylaminomethenimino-6-chloropurine (3)

[0059] First add 40mL of N,N-dimethylformamide to the dry reaction bottle, and add 35mL of POCl dropwise at 0℃~10℃ 3 , formulated as POCl 3 N,N-dimethylformamide solution, set aside; then in another dry reaction bottle, add 200mL of 1,2-dichloroethane and 20g of guanine (2), at 20℃~30℃ , dropwise add the prepared N,N-dimethylformamide solution of phosphorus oxychloride. After dripping, keep stirring for 1 hour, then heat up and reflux for 5 to 8 hours to complete the reaction, and cool to obtain 2-dimethylaminomethenimino-6-chloropurine (3). The intermediate product (3) does not need to be prepared from the reaction solution Separated from, the reaction solution containing the intermediate product (3) is for subsequent use;

[0060] b) Preparat...

Embodiment 3

[0067] The synthesis of embodiment three 2-amino-6-chloropurine (1)

[0068] The synthetic method of 2-amino-6-chloropurine (1) comprises the following steps successively:

[0069] a) Preparation of 2-dimethylaminomethenimino-6-chloropurine (3)

[0070] First, add 40mL of N,N-dimethylformamide to the dry reaction bottle, and add 35mL of POCl dropwise at 0-10°C 3 , formulated as POCl 3 N,N-dimethylformamide solution, set aside; then in another dry reaction bottle, add 200mL of 1,2-dichloroethane and 20g of guanine (2), at 20℃~30℃ , dropwise add the prepared N,N-dimethylformamide solution of phosphorus oxychloride. After dripping, keep stirring for 1 hour, then heat up and reflux for 5 to 8 hours to complete the reaction, and cool to obtain 2-dimethylaminomethenimino-6-chloropurine (3). The intermediate product (3) does not need to be prepared from the reaction solution Separated from, the reaction solution containing the intermediate product (3) is for subsequent use;

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com