Method for leaching and extracting valuable metal and sulfur element from low nickel matte

A technology of valuable metals and sulfur elements, applied in the field of metallurgy, can solve problems such as harsh process conditions and high energy consumption, and achieve the effects of short process flow, reduced investment costs, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for extracting valuable metals and sulfur elements by low nickel matte leaching, low nickel matte components: 20.98% nickel, 8.97% copper, 0.76% cobalt, 41.29% iron, 24.35% sulfur, the valuable metals and sulfur are extracted through the following steps element:

[0044] (1) Raw material pretreatment: crush 100g of low-matte nickel into powder or granular form, and pass through a sieve size standard of not higher than 200 mesh after the low-matte nickel is crushed;

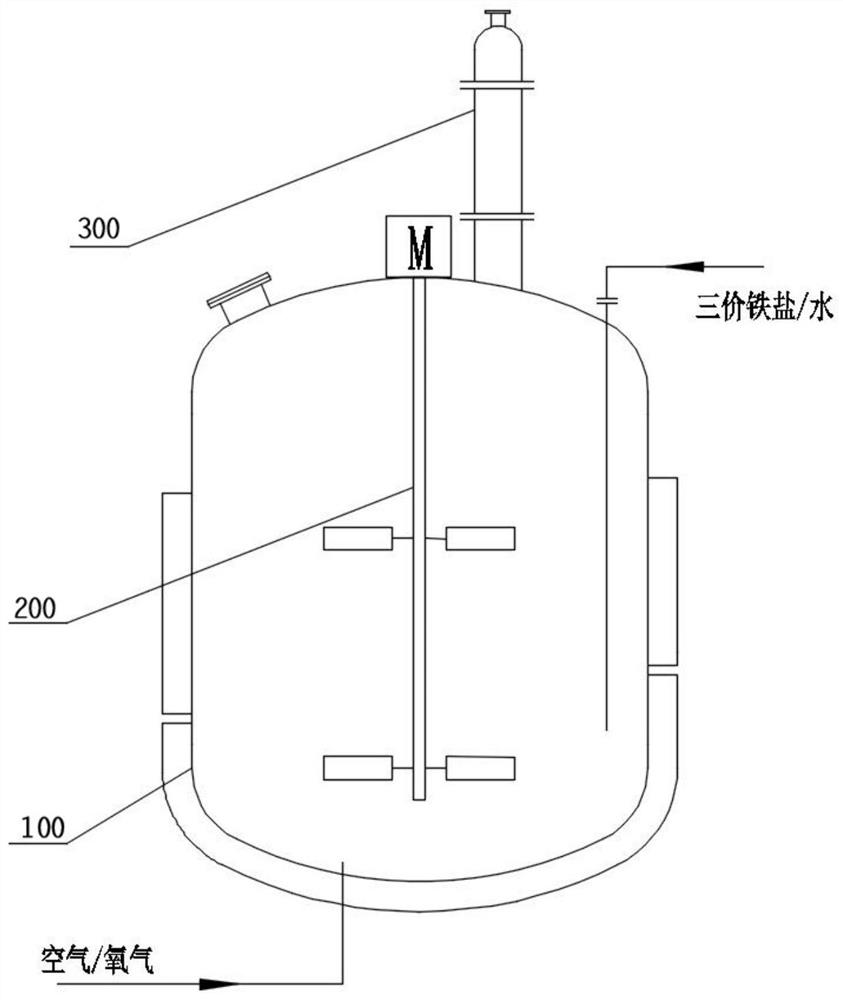

[0045] (2) Oxidative leaching: Add 400mL ferric chloride with an iron ion concentration of 1.0mol / L and 100mL carbon disulfide organic solvent to the pulverized material obtained in step (1), blow air from the bottom under constant stirring, and control the reaction The temperature is 100°C, the reaction time is 5 hours, and water and ferric salt are added to the reaction system every 40 minutes to maintain the concentration of ferric ions in the water phase at 1.0-1.5mol / L;

[0046] (3) Separatio...

Embodiment 2

[0050] A method for extracting valuable metals and sulfur elements by low nickel matte leaching, low nickel matte components: nickel 23.66%, copper 6.73%, cobalt 1.36%, iron 38.04%, sulfur 24.35%, extracting valuable metals and sulfur through the following steps element:

[0051] (1) Raw material pretreatment: crush 100g of low-matte nickel into powder or granular form, and pass through a sieve size standard of not higher than 200 mesh after the low-matte nickel is crushed;

[0052] (2) Oxidative leaching: adding 1000mL ferric ion concentration to ferric sulfate of 2.0mol / L and 3000mL carbon tetrachloride organic solvent in step (1) gained pulverized material, in the state of constantly stirring, blow into oxygen from the bottom, and Control the reaction temperature to 120°C, the reaction time to 6h, add water and ferric salt to the reaction system every 30min, and maintain the concentration of ferric ion in the water phase at 2.0-2.5mol / L;

[0053] (3) Separation treatment: ...

Embodiment 3

[0056] A method for extracting valuable metals and sulfur elements by low nickel matte leaching, low nickel matte components: nickel 26.55%, copper 5.7%, cobalt 1.06%, iron 32.19%, sulfur 27.45%, extracting valuable metals and sulfur through the following steps element:

[0057] (1) Raw material pretreatment: crush 100g of low-matte nickel into powder or granular form, and pass through a sieve size standard of not higher than 200 mesh after the low-matte nickel is crushed;

[0058] (2) Oxidative leaching, add 1000mL ferric ion concentration to iron nitrate of 3mol / L and 2000mL tetrachloroethane organic solvent in the pulverized material gained in step (1), blow into air from the bottom under the state of constantly stirring, and control The reaction temperature is 80° C., and the reaction time is 10 h. Add water and ferric salt to the reaction system every 20 minutes to maintain the concentration of ferric ions in the water phase at 3.0-5.5mol / L;

[0059] (3) Separation trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com