Polypropylene electret master batch material, method for preparing same and application of polypropylene electret master batch material

A polypropylene and electret technology, which is applied in the field of polypropylene electret masterbatch materials and its preparation, can solve the problems of high resistance, low filtration efficiency of melt-blown polypropylene fibers, high electret voltage, etc., and achieve high yield, Electret effect is obvious, the effect of reducing the electret voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

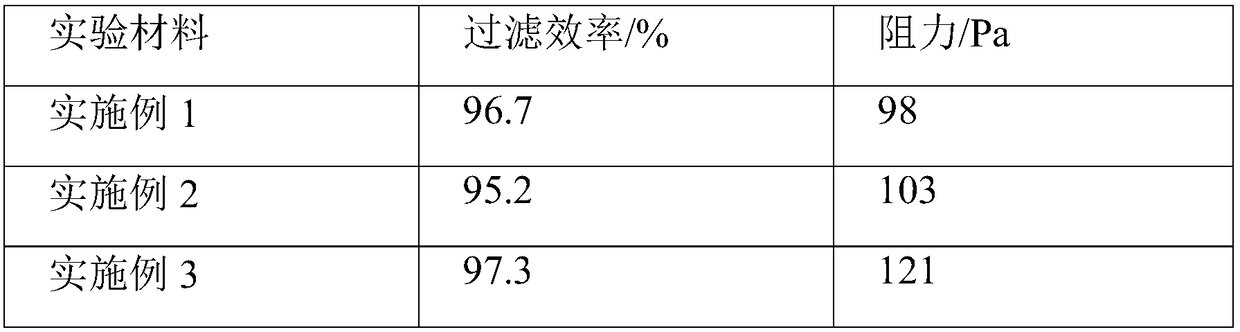

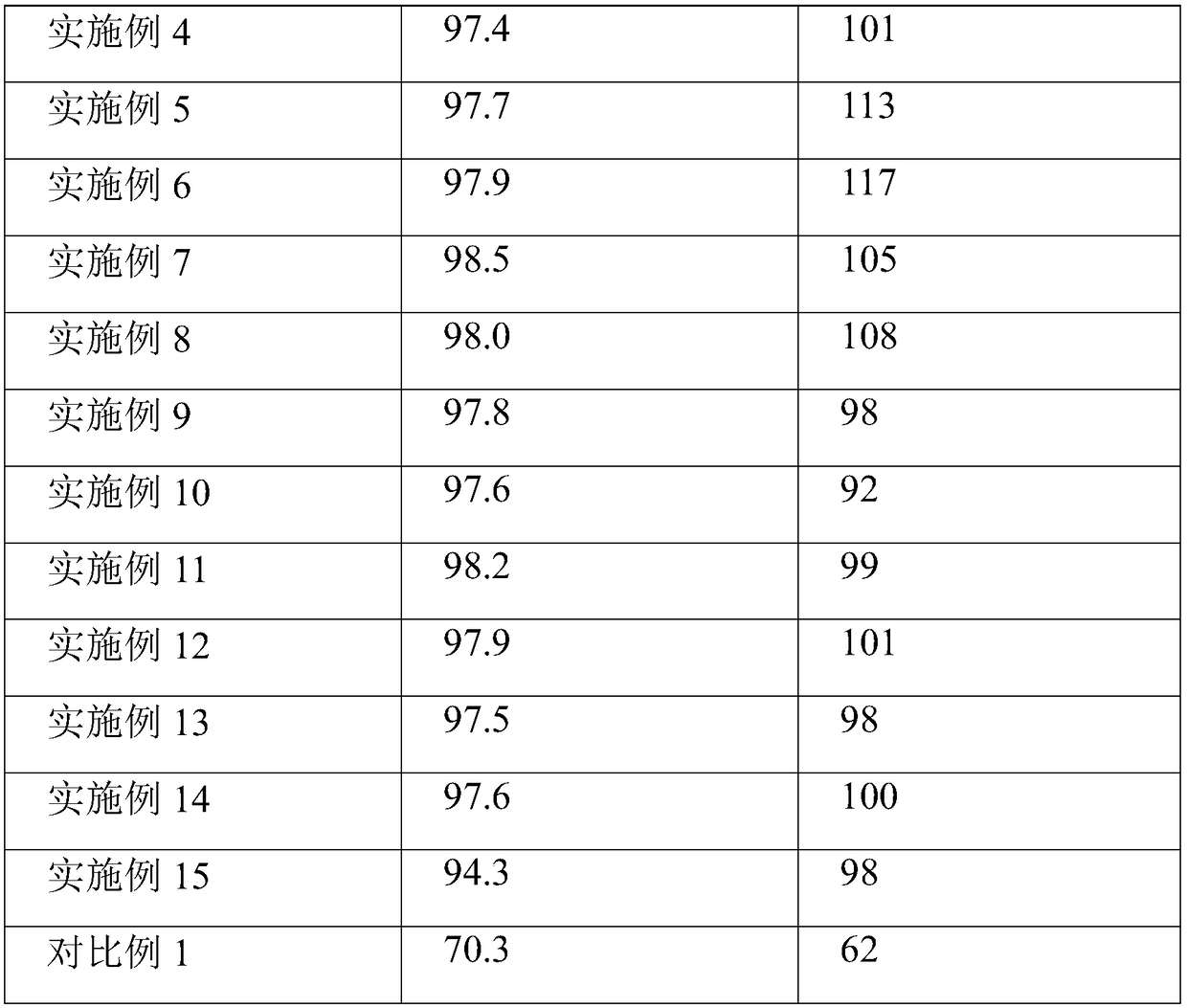

Embodiment 1

[0037] Using 87.6 parts of PP (homopolypropylene PPH, melt index 1000g / 10min), 12 parts of N,N'-ethylene bisstearamide, 0.2 parts of antioxidant, 0.2 parts of sebacic acid bis-2 , 2,6,6-tetramethylpiperidinol ester. Mixed by a high-speed mixer, transferred to a twin-screw extruder with a total of 12 sections of barrels with an aspect ratio of 48 for melt blending and extrusion, the temperature of the melting section is 160-210°C, granulation and drying of the particles to obtain polypropylene electret granular material.

Embodiment 2

[0039] Use 87.6 parts of PP (homopolypropylene PPH, melt index 1000g / 10min), 12 parts of natural wax, 0.2 part of antioxidant, and 0.2 part of 2-hydroxy-4-methoxybenzophenone. Mixed by a high-speed mixer, transferred to a twin-screw extruder with a total of 12 sections of barrels with an aspect ratio of 48 for melt blending and extrusion, the temperature of the melting section is 160-210°C, granulation and drying of the particles to obtain polypropylene electret granular material.

Embodiment 3

[0041] Using 87.6 parts of PP (homopolypropylene PPH, melt index 1000g / 10min), 12 parts of plexiglass, 0.2 parts of antioxidant, 0.2 parts of 2-hydroxy-4-dodecyloxybenzophenone . Mixed by a high-speed mixer, transferred to a twin-screw extruder with a total of 12 sections of barrels with an aspect ratio of 48 for melt blending and extrusion, the temperature of the melting section is 160-210°C, granulation and drying of the particles to obtain polypropylene electret granular material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com