Method for extracting vanadium by utilizing sodium-modified vanadium extraction tailings and converter vanadium slag

A technology for sodium extraction of vanadium and converter vanadium slag, applied in the chemical industry, can solve the problems of low extraction rate, achieve the effect of improving vanadium conversion rate, convenient operation, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

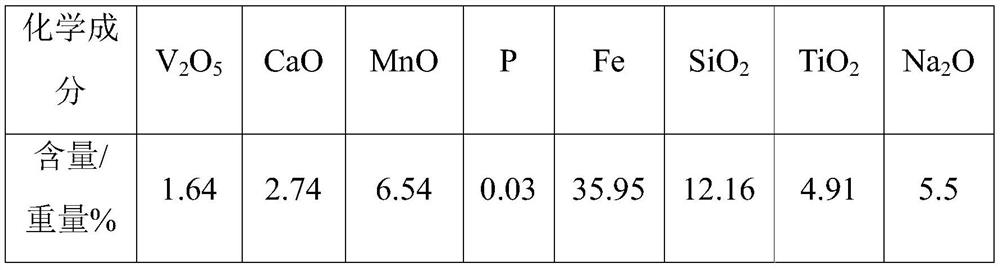

[0064] (1) Get 200g of the tailings of vanadium extraction in Table 1, and dry it in an oven until the water content is 0.1% by weight (the temperature of drying is 140°C, and the time of drying is 120min), and then the dried slag is dried in a ball mill. The dried sodium vanadium extraction tailings are ground to a particle size of less than 0.125mm;

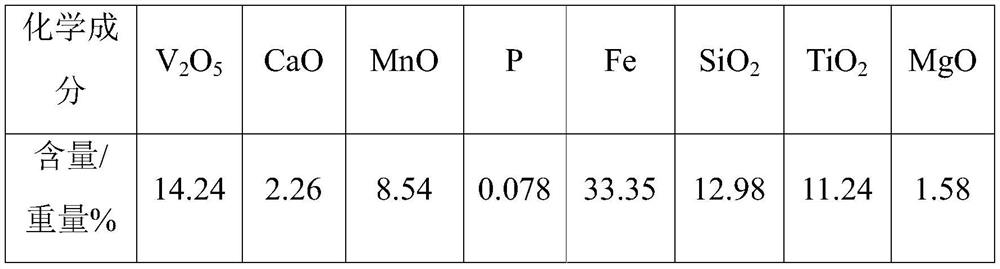

[0065] (2) get the vanadium-extracting tailing slag after the grinding of 150g step (1), add the converter vanadium slag fine powder, 1.65g calcium sulfate, 0.5g manganese sulfate and 0.5g magnesium sulfate in 15g table 2, in Carry out mechanical activation in the high-energy ball mill, the rotating speed of mechanical activation is 500r / min, the time of mechanical activation is 30min, obtains 167.65g mixture;

[0066] (3) Put the mixture obtained in step (2) into a muffle furnace, and roast it at 820°C for 180min to obtain clinker (the discharge temperature of the clinker is 700°C), and V in the clinker 2 o 5 The content of ...

Embodiment 2

[0068] (1) Get 200g of the tailings of vanadium extraction in Table 1, and dry it in an oven until the water content is 0.05% by weight (the temperature of drying is 500°C, and the time of drying is 40min), and then the dried slag is dried in a ball mill. The dried sodium vanadium extraction tailings are ground to a particle size of less than 0.125mm;

[0069] (2) get the vanadium-extracting tailings of vanadium extraction after the fine grinding of 15g step (1), add the converter vanadium slag refined powder in 150g table 2, 4.95g calcium sulfate, 1.05g manganese sulfate and 1.0g magnesium sulfate, in Carry out mechanical activation in the high-energy ball mill, the rotating speed of mechanical activation is 800r / min, the time of mechanical activation is 5min, obtains 172.00g mixture;

[0070] (3) Put the mixture obtained in step (2) into a muffle furnace, and roast it at 820°C for 180min to obtain clinker (the discharge temperature of the clinker is 700°C), and V in the clin...

Embodiment 3

[0072] (1) Get 200g of the tailings of vanadium extraction in Table 1, and dry it in an oven until the water content is 0.1% by weight (the temperature of drying is 300°C, and the time of drying is 60min), and then dry it in a ball mill. The dried sodium vanadium extraction tailings are ground to a particle size of less than 0.125mm;

[0073] (2) Get the vanadium-extracting tailings after the grinding of 150g step (1), add the converter vanadium slag refined powder in 50g table 2, 6g calcium sulfate, 1.0g manganese sulfate and 1.0g magnesium sulfate, in high energy Carry out mechanical activation in the ball mill, the rotating speed of mechanical activation is 300r / min, the time of mechanical activation is 10min, obtains 208.00g mixture;

[0074] (3) Put the mixture obtained in step (2) into a muffle furnace, and roast it at 950°C for 70 minutes to obtain clinker (the discharge temperature of the clinker is 700°C), and V in the clinker 2 o 5 The content of the clinker is 4.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com